Ultra-wide-range fiber Bragg grating temperature sensor

An optical fiber Bragg, temperature sensor technology, applied in thermometers, thermometers, instruments and other directions with physical/chemical changes, can solve the problems of difficult high temperature sensing, low mechanical strength, insufficient stability, etc., to enhance mechanical strength and facilitate production. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

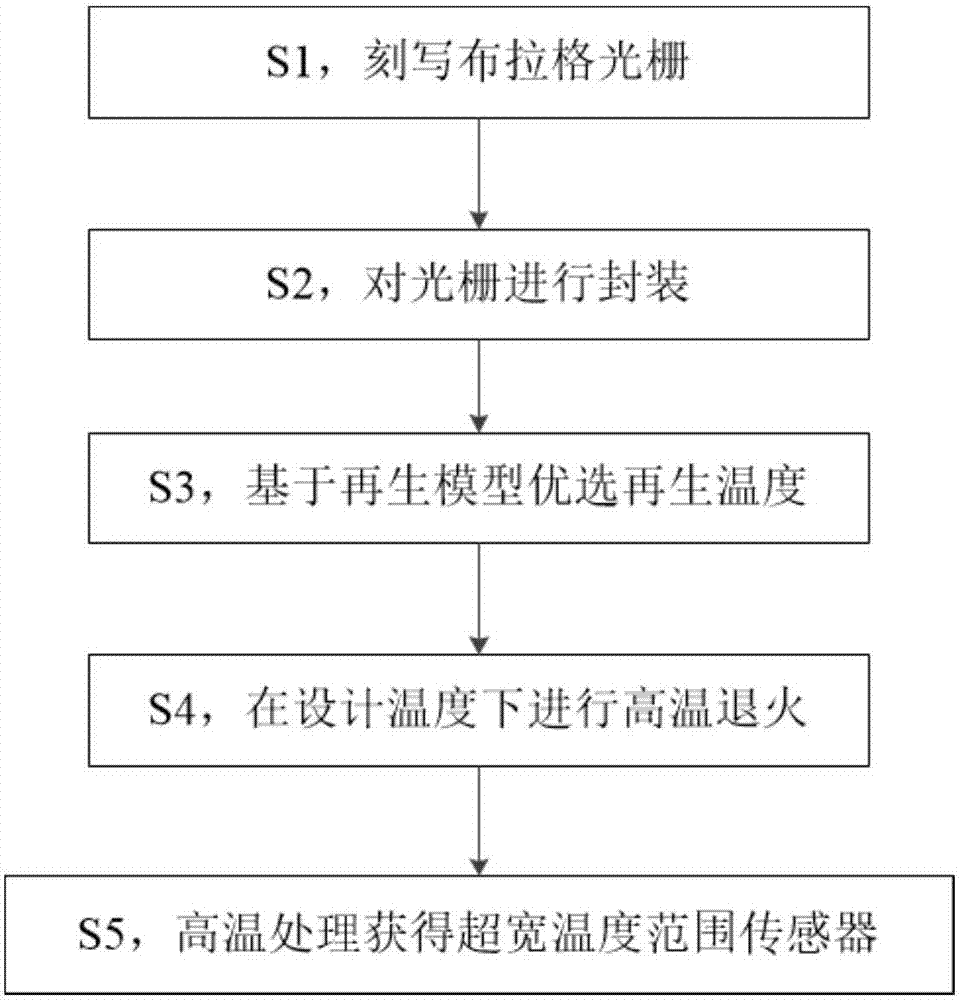

[0032] figure 1 Show the manufacturing process of a kind of ultra-wide range fiber Bragg grating temperature sensor of the present invention, specifically comprise the following steps:

[0033] 1) Writing a seed grating on a gold-coated fiber using a UV laser and a phase mask.

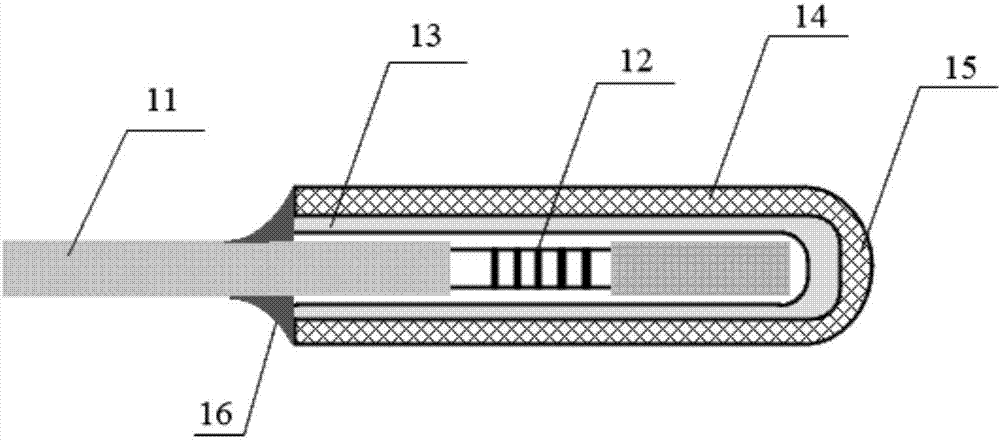

[0034] 2) Refer to attached figure 2 As shown, a high-temperature ceramic capillary inner tube 13 with an inner diameter slightly larger than the outer diameter of the optical fiber by 2-3 microns, an outer diameter of 1 mm, and a length of 100 mm and a stainless steel outer tube 14 with an inner diameter of 1 mm, an outer diameter of 2 mm, and a length of 100 mm are passed through the process. The composite capillary is assembled into a composite capillary, one end of the stainless steel tube is sintered and sealed, and then the engraved Bragg grating 12 is inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com