Preparation method for significantly enhancing surface photo-voltage signal of BiOCl

A surface photovoltage and signal technology, applied in the fields of material chemistry and photocatalytic materials, can solve the problems of poor controllability and complicated operation, and achieve the effects of simple operation, easy availability of raw materials and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

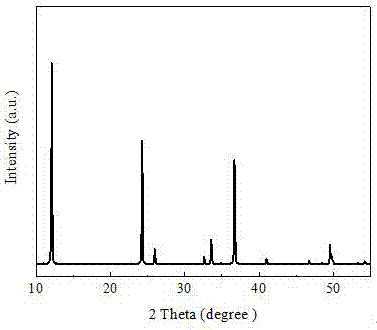

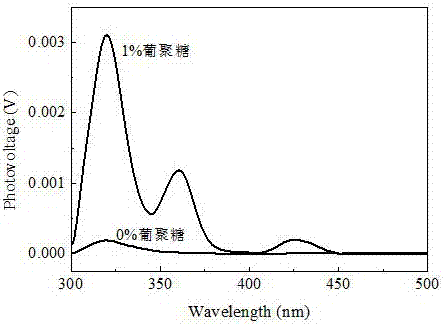

[0032] In the first step, bismuth nitrate is dissolved in glacial acetic acid. Specifically, 5 g of bismuth nitrate was dissolved in 40 mL of glacial acetic acid, and 20,000 dextran was added. The molar number of dextran was 1% of that of bismuth nitrate.

[0033] In the second step, 10 mL of KCl solution was added dropwise to the bismuth nitrate-glacial acetic acid solution, and the number of moles of KCl was equal to the number of moles of bismuth nitrate. The resulting precipitate was transferred to a hydrothermal reaction kettle, hydrothermally treated at 180°C for 24 hours, and cooled naturally to room temperature.

[0034] In the third step, wash with deionized water and then wash with alcohol for 1-2 times, take out the powder and disperse it in alcohol, dry at 80°C to obtain a sample, and test the surface photovoltage.

Embodiment 2

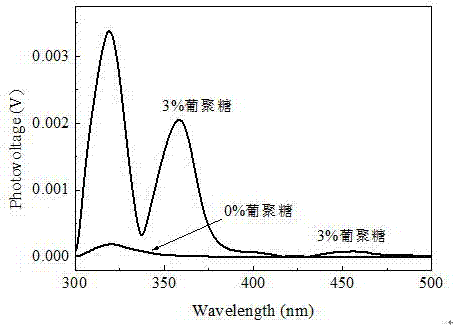

[0038] In the first step, bismuth nitrate is dissolved in glacial acetic acid. Specifically, 5 g of bismuth nitrate was dissolved in 50 mL of glacial acetic acid, and dextran 20,000 was added. The molar number of dextran was 3% of that of bismuth nitrate.

[0039] In the second step, 10 mL of KCl solution was added dropwise to the bismuth nitrate-glacial acetic acid solution, and the number of moles of KCl was equal to the number of moles of bismuth nitrate. The resulting precipitate was transferred to a hydrothermal reactor, hydrothermally treated at 160°C for 24 hours, and cooled naturally to room temperature.

[0040] In the third step, wash with deionized water and then wash with alcohol for 1-2 times, take out the powder and disperse it in alcohol, dry at 60°C to obtain a sample, and test the surface photovoltage.

[0041] Compared with Comparative Example 1, in Example 2, 20,000 dextran was added, the molar number of dextran was 3% of that of bismuth nitrate, the hydrot...

Embodiment 3

[0044] In the first step, bismuth nitrate is dissolved in glacial acetic acid. Specifically, 5 g of bismuth nitrate was dissolved in 60 mL of glacial acetic acid, and 20,000 dextran was added. The molar number of dextran was 4% of that of bismuth nitrate.

[0045] In the second step, 10 mL of KCl solution was added dropwise to the bismuth nitrate-glacial acetic acid solution, and the number of moles of KCl was equal to the number of moles of bismuth nitrate. The resulting precipitate was transferred to a hydrothermal reactor, hydrothermally treated at 170°C for 24 hours, and naturally cooled to room temperature.

[0046] In the third step, wash with deionized water and then wash with alcohol for 1-2 times, take out the powder and disperse it in alcohol, dry at 70°C to obtain a sample, and test the surface photovoltage.

[0047] Compared with Comparative Example 1, in Example 3, 20,000 dextran was added, the molar number of dextran was 4% of that of bismuth nitrate, the hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com