Preparation method for cellulose base water-absorbent resin

A water-absorbent resin and cellulose-based technology, which is applied in the field of preparation of cellulose-based water-absorbent resin, can solve the problems of poor water retention capacity and poor salt resistance, and achieve the effects of improving water retention performance, salt resistance, and strong water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

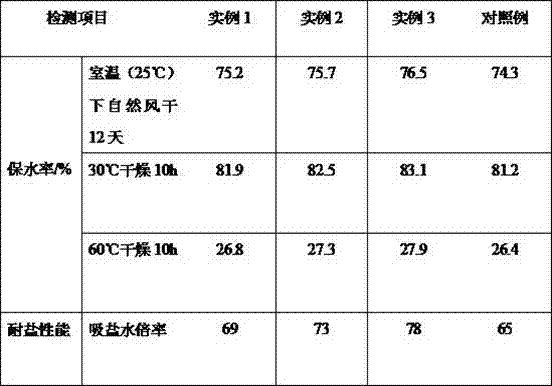

example 1

[0020] Take 30g of cellulose, 5mL of ethylenediamine and 100mL of 25% oxidant solution in a beaker, place the beaker in a water bath, control the temperature of the water bath at 70°C, stir and react for 1 hour and then filter to obtain a filter residue. , 15g of N-vinylpyrrolidone and 100mL of solvent were added to a three-necked flask equipped with a thermometer and a reflux device, and the three-necked flask was moved into a digital speed measuring constant temperature magnetic stirrer, and stirred at a temperature of 120°C and a speed of 200r / min After mixing for 10 minutes, add 0.1 g of initiator and 0.3 g of cross-linking agent to the three-necked flask, keep warm for 2 hours and then filter to obtain a filter cake. Then put the three-necked flask in a water bath, control the temperature of the water bath to 60°C, and stir the reaction for 1 hour to obtain the product, pour the product into a rotary evaporator, and concentrate by rotary evaporation for 25 minutes to obtai...

example 2

[0022] Take 35g of cellulose, 7mL of ethylenediamine and 150mL of 25% oxidant solution in a beaker, place the beaker in a water bath, control the temperature of the water bath at 75°C, stir and react for 2 hours and then filter to obtain a filter residue. , 18g of N-vinylpyrrolidone and 150mL of solvent were added to a three-necked flask equipped with a thermometer and a reflux device, and the three-necked flask was moved into a digital speed measuring constant temperature magnetic stirrer, and stirred at a temperature of 125°C and a speed of 250r / min After mixing for 13 minutes, add 0.2 g of initiator and 0.4 g of cross-linking agent to the three-necked flask, keep warm for 3 hours and then filter to obtain a filter cake. Then put the three-necked flask in a water bath, control the temperature of the water bath to 65°C, and stir the reaction for 2 hours to obtain the product, pour the product into a rotary evaporator, and concentrate by rotary evaporation for 28 minutes to obt...

example 3

[0024] Add 40g of cellulose, 8mL of ethylenediamine and 200mL of 25% oxidant solution into a beaker, place the beaker in a water bath, control the temperature of the water bath at 80°C, stir and react for 2 hours and then filter to obtain a filter residue. , 20g of N-vinylpyrrolidone and 200mL of solvent were added to a three-necked flask equipped with a thermometer and a reflux device, and the three-necked flask was moved into a digital speed measuring constant temperature magnetic stirrer, and stirred at a temperature of 130°C and a speed of 300r / min After mixing for 15 minutes, add 0.3 g of initiator and 0.5 g of cross-linking agent to the three-necked flask, keep warm for 3 hours and then filter to obtain a filter cake. Then put the three-necked flask in a water bath, control the temperature of the water bath to 70°C, and stir the reaction for 2 hours to obtain the product, pour the product into a rotary evaporator, and concentrate by rotary evaporation for 30 minutes to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com