Oil-based drilling fluid flushing liquor for well cementation as well as resource recycling method and application of flushing liquor

An oil-based drilling fluid and flushing fluid technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of waste of useful resources of surfactants, environmental pollution, difficulty, etc., achieve good flushing effect, enhance Elution ability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

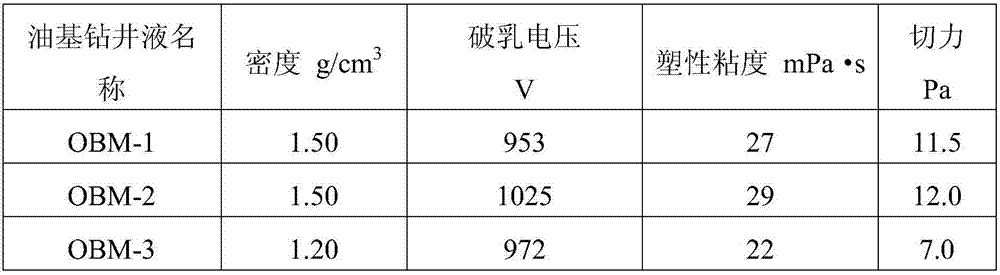

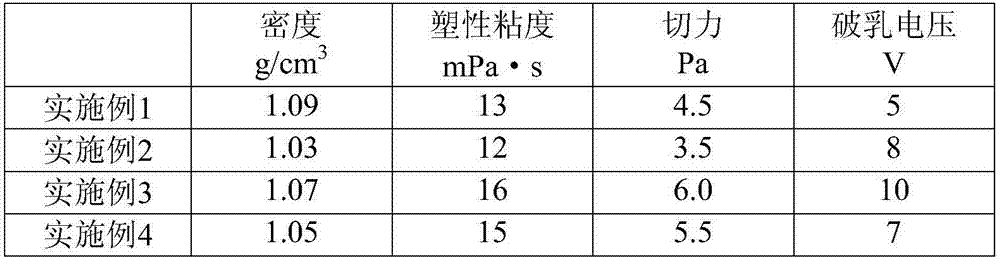

[0047] Add 20 parts by weight of coconut oleic acid triethanolamide to 70 parts of seawater, stir for 30 minutes, and dissolve for 30 minutes; then add 10 parts by weight of sodium metasilicate, stir for 28 minutes, and dissolve for 60 minutes to obtain the flushing solution. Indicated in Table 2.

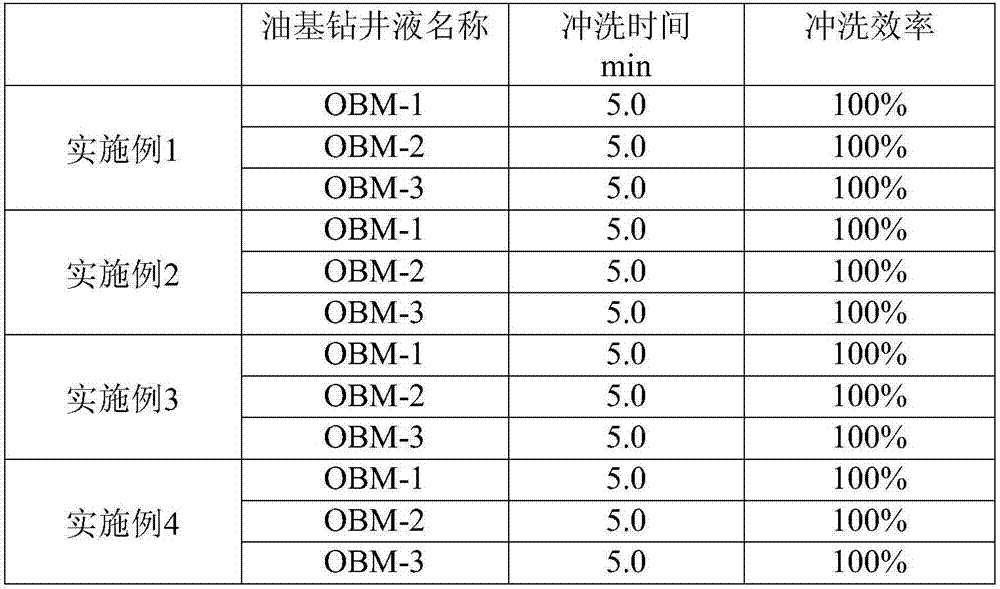

[0048] Washing tests were carried out on OBM-1, OBM-2, and OBM-3 using the flushing liquid, and the flushing effect is shown in Table 3. At the same time, the flushing liquid after use was obtained, and the performance and component content of the flushing liquid after flushing were shown in Table 4.

[0049] 100 parts by weight of OBM-1 to OBM-3 correspond to the base oil used, 5 parts by weight of OBM-1 to OBM-3 correspond to the main emulsifier used, and 0.5 parts by weight of OBM-1 to OBM-3 correspond to the used Co-emulsifier, stirred at 10000rpm for 20 minutes, then added 50 parts by weight of the above-mentioned flushing liquid after use, stirred for 40 minutes, then added 2...

Embodiment 2

[0051] Add 5 parts by weight of SP-20 to 92 parts of tap water, stir for 10 minutes, and dissolve for 30 minutes; then add 3 parts by weight of heptasodium diethylenetriamine pentamethylene phosphate, stir for 10 minutes, dissolve for 30 minutes, and obtain the rinse Fluid, the performance of the flushing fluid is shown in Table 2.

[0052] Washing tests were carried out on OBM-1, OBM-2, and OBM-3 using the flushing liquid, and the flushing effect is shown in Table 3. At the same time, the flushing liquid after use was obtained, and the performance and component content of the flushing liquid after flushing were shown in Table 4.

[0053] 100 parts by weight of OBM-1 to OBM-3 correspond to the base oil used, 6 parts by weight of OBM-1 to OBM-3 correspond to the main emulsifier used, and 1 part by weight of OBM-1 to OBM-3 corresponds to the used Co-emulsifier, stirred at 10000rpm for 20 minutes, then added 50 parts by weight of the above-mentioned flushing liquid after use, sti...

Embodiment 3

[0055] Add 12 parts by weight of lauric acid monoethanolamide in 80 parts of lake water, stir for 20 minutes, and dissolve for 45 minutes; then add 8 parts by weight of sodium metasilicate, stir for 20 minutes, and dissolve for 50 minutes to obtain the washing solution, and the performance of the washing solution is expressed In Table 2.

[0056] Washing tests were carried out on OBM-1, OBM-2, and OBM-3 using the flushing liquid, and the flushing effect is shown in Table 3. At the same time, the flushing liquid after use was obtained, and the performance and component content of the flushing liquid after flushing were shown in Table 4.

[0057] 100 parts by weight of OBM-1~OBM-3 correspond to the base oil used, 7 parts by weight of OBM-1~OBM-3 correspond to the main emulsifier used, and 2 parts by weight of OBM-1~OBM-3 correspond to the used Co-emulsifier, stirred at 10000rpm for 20 minutes, then added 50 parts by weight of the above-mentioned flushing liquid after use, stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com