Tricobalt tetroxide composite α-type iron oxide worm-like nanostructure array photoanode, preparation method and application thereof

A technology of cobalt tetroxide and nanostructure, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of slow oxygen evolution reaction kinetics, short hole diffusion distance, poor conductivity, etc. Achieve good oxygen evolution catalytic activity, low price, and the effect of inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

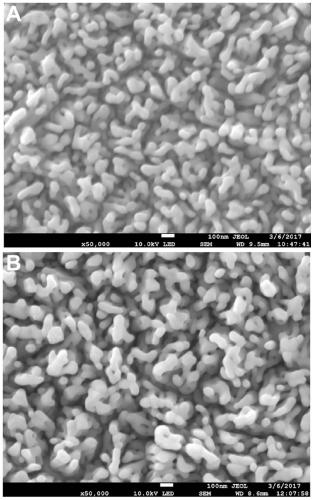

[0026] Preparation of tricobalt tetroxide composite α-type iron oxide worm-like nanostructure array photoanode

[0027] (1) Sonicate the FTO glass with acetone for 15 minutes, then wash it with water; then use it for 15 minutes with absolute ethanol, and then wash it with water; finally use deionized water for 15 minutes, then soak it in 0.15M FeCl 3 ·6H 2 Under the condition of 100°C in O solution, carry out hydrothermal reaction for 4h, then raise the temperature to 550°C in the muffle furnace and keep it for 1h, then raise the temperature to 730°C and keep it for 15min, then cool down to obtain FTO glass loaded with α-type iron oxide, The α-type iron oxide is in the form of a worm-like nanostructure array;

[0028] (2) Co(NO 3 ) 2 ·6H 2 O, NH 4 F and CO(NH 2 ) 2 Mix and prepare the precursor solution at a weight ratio of 2:7:10, then place the precursor solution and the FTO glass loaded with α-type iron oxide in step (1) in the reaction vessel at the same time and re...

Embodiment 2

[0031] Preparation of tricobalt tetroxide composite α-type iron oxide worm-like nanostructure array photoanode

[0032] (1) Sonicate the FTO glass with acetone for 10 minutes and wash it with water; then use absolute ethanol for 10 minutes and wash it with water; finally use deionized water for 10 minutes and immerse it in 0.12M FeCl 3 ·6H 2 Under the condition of 120°C in the O solution, carry out the hydrothermal reaction for 3h, then raise the temperature to 550°C in the muffle furnace and keep it for 1h, then raise the temperature to 700°C and keep it for 15min, then cool down to obtain FTO glass loaded with α-type iron oxide, The α-type iron oxide is in the form of a worm-like nanostructure array;

[0033] (2) Co(NO 3 ) 2 ·6H 2 O, NH 4 F and CO(NH 2 ) 2 Mix and prepare the precursor solution at a weight ratio of 1:7:10, then place the precursor solution and the FTO glass loaded with α-type iron oxide in step (1) in the reaction vessel at the same time and react at ...

Embodiment 3

[0036] Preparation of tricobalt tetroxide composite α-type iron oxide worm-like nanostructure array photoanode

[0037] (1) Sonicate the FTO glass with acetone for 12 minutes, then wash it with water; then use absolute ethanol for 12 minutes, then wash it with water; finally use deionized water for 12 minutes, then immerse it in 0.1M FeCl 3 ·6H 2 Under the condition of 110°C in O solution, the hydrothermal reaction was carried out for 6h, then the temperature was raised to 550°C in the muffle furnace and kept for 1h, then the temperature was raised to 715°C and kept for 15min, and the FTO glass loaded with α-type iron oxide was obtained by cooling down. The α-type iron oxide is in the form of a worm-like nanostructure array;

[0038] (2) Co(NO 3 ) 2 ·6H 2 O, NH 4 F and CO(NH 2 ) 2 Mix and prepare the precursor solution at a weight ratio of 3:7:10, then place the precursor solution and the FTO glass loaded with α-type iron oxide in step (1) in the reaction vessel at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com