Lithium ion reinforced inert anode for molten salt electrolysis system and preparation method thereof

An inert anode and molten salt electrolysis technology, which is applied in the field of metallurgy, can solve the problems of selective dissolution of metal phases, loss of protection, and destruction of oxide films, etc., and achieve the effects of long electrode life, lower prices, and more selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using 310S stainless steel as the substrate, chromium oxide and lithium oxide (mass ratio of chromium oxide:lithium oxide = 83.6:16.4) were used as coating materials, and a layer of 10 μm thick LiCrO was prepared on the surface of the stainless steel substrate by plasma spraying. 2 (Cr 2 o 3 · Li 2 O) oxide film layer, obtain the chromium oxide inert anode that the lithium ion of matrix is strengthened with stainless steel.

[0021] At 750°C, with CaCl 2 -NaCl-CaO molten salt (molar ratio CaCl 2 :NaCl:CaO=48:48:4%) as electrolyte, with TiO 2 As the cathode, the service behavior of the lithium ion-enhanced chromium oxide inert anode was tested by means of 2.9V constant cell voltage electrolysis. The results show that the inert anode in CaCl 2 After working in the -NaCl-CaO system for 1000 hours, it can still maintain stable oxygen evolution.

Embodiment 2

[0023] Using metal nickel as the substrate, a layer of nickel oxide is formed on the surface by air pre-oxidation, and then a layer of 12 μm is prepared on the surface of nickel oxide by ion implantation with lithium oxide as the raw material and ion beam energy of 200keV. thick lithiated nickel oxide (Li 0.15 Ni 1.05 o 2 ) layer to obtain a lithium-ion-enhanced nickel oxide inert anode based on nickel metal.

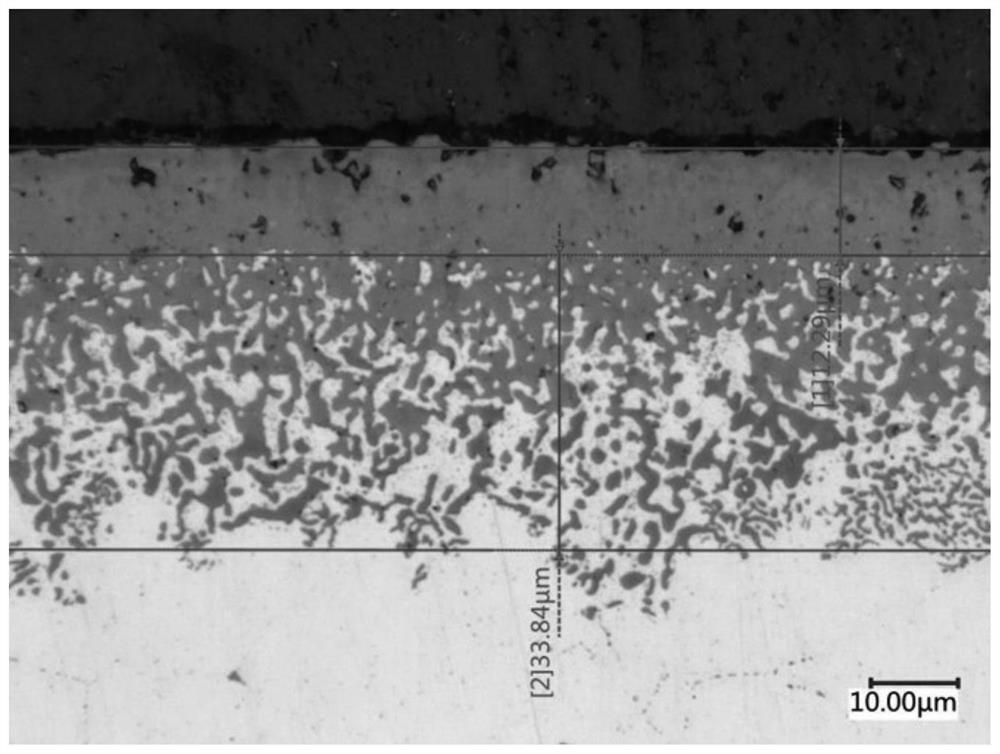

[0024] The structure of the inert anode is as follows figure 1 As shown, its cross-sectional optical photograph is shown as figure 2 shown. It can be seen from the figure that the outer layer is a dense lithiated nickel oxide layer with a thickness of 12 μm, and there is a cross distribution layer of metal oxide and metal with a thickness of 30 μm between the lithiated nickel oxide layer and the metal substrate.

[0025] At 650°C, with LiCl-Li 2 O molten salt (molar ratio LiCl:Li 2 O=98:2) was used as the electrolyte, and the spent fuel oxide was used as the cat...

Embodiment 3

[0027] Using nickel-cobalt alloy as the substrate, a layer of 30 μm thick LiCoO was prepared on the surface by electrochemical pre-oxidation method. 2 (Co 2 o 3 · Li 2 O) to obtain a lithium-ion-enhanced cobalt oxide inert anode based on a nickel-cobalt alloy.

[0028] At 850°C, with CaCl 2 -CaO molten salt (molar ratio CaCl 2 :CaO=98:2) as electrolyte, with CaWO 4 As the cathode, at 200mA / cm 2 The service behavior of the lithium-ion-enhanced cobalt oxide inert anode was tested by constant current electrolysis under the condition of anodic current density. The results show that the inert anode in CaCl 2 - After working in the CaO system for 100 hours, it can still maintain stable oxygen evolution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com