A nanoporous Ni-Fe bimetallic layered hydroxide electrocatalytic material for oxygen evolution and its preparation method and application

A bimetallic layered, hydroxide-electric technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of reducing the binding force between the catalyst and the substrate, Difficult to large-scale industrial production, complex process and other issues, to achieve good oxygen evolution catalytic activity, good stability, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the nanoporous Ni-Fe-LDH electrocatalytic material for oxygen evolution of the present embodiment comprises the following steps:

[0038] (1) Sample preparation: A Ni-Fe alloy sheet with a thickness of 0.2mm and a composition of 79wt% Ni, 18wt% Fe, and 3% impurity elements was used as the base metal, and cut into a rectangle of 3.5cm×0.5cm, among which, The upper part with a length of 1.5cm is the clamping part, which is used to connect with the fixture, and the lower part with a length of 2cm is the actual use part, which is immersed in the electrolyte to participate in the anodic oxidation reaction.

[0039] (2) Sample cleaning: Use acetone, isopropanol and alcohol to remove the oil stain and oxide layer on the surface of the Ni-Fe alloy sheet in an ultrasonic environment. Ultrasonic cleaning in acetone and isopropanol for 20 minutes, then ultrasonic cleaning in alcohol for 20 minutes; after ultrasonic cleaning, dry it for later use.

[0040...

Embodiment 2

[0052] The preparation method of the nanoporous Ni-Fe-LDH electrocatalytic material for oxygen evolution of the present embodiment comprises the following steps:

[0053] (1) Sample preparation: the same as step (1) of Example 1.

[0054] (2) Sample cleaning: the same as step (2) of Example 1.

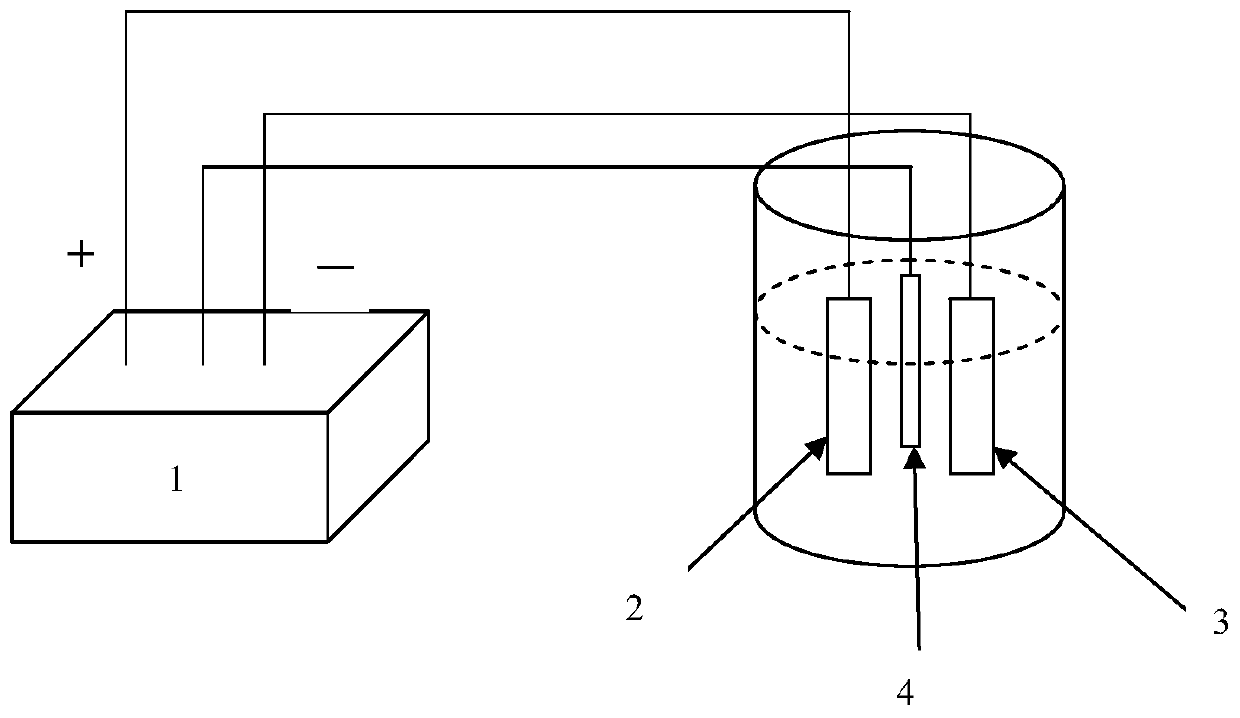

[0055] (3) Anodizing: add ammonium fluoride, water, ethylene glycol and phosphoric acid to the container to form an electrolyte, where the concentrations of ammonium fluoride, water, ethylene glycol and phosphoric acid in the electrolyte are 0.5wt% and 10wt% respectively , 40wt%, 49.5wt%, fix one end of the cleaned Ni-Fe alloy sheet on the anode fixture, and immerse the other end in the electrolyte for anodization. During the anodization process, the temperature of the electrolyte is kept at 20°C. CHI 660D Electrochemical Workstation 1 produced by Chenhua Instrument Co., Ltd., such as figure 1 As shown, a three-electrode system is adopted, with Ni-Fe alloy sheet 2 as the working elec...

Embodiment 3

[0061] (1) Sample preparation: the same as step (1) of Example 1.

[0062] (2) Sample cleaning: the same as step (2) of Example 1.

[0063] (3) Anodizing: add ammonium fluoride, water, ethylene glycol and phosphoric acid to the container to form an electrolyte, wherein the concentrations of ammonium fluoride, water, ethylene glycol and phosphoric acid in the electrolyte are 3wt%, 25wt%, 33wt%, 39wt%, one end of the cleaned Ni-Fe alloy sheet is fixed on the anode fixture, and the other end is immersed in the electrolyte for anodization. During the anodization process, the temperature of the electrolyte is kept at 20°C. CHI 660D Electrochemical Workstation 1 produced by Hua Instrument Co., Ltd., such as figure 1 As shown, a three-electrode system is adopted, with Ni-Fe alloy sheet 2 as the working electrode, pure platinum sheet 3 as the counter electrode, and saturated calomel electrode 4 (SCE) as the reference electrode. The speed is increased to 7.5V, and then constant volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com