Flexible laying structure and construction method suitable for steel bridge deck at damp and hot high-temperature region

A construction method and technology for steel bridge decks, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult construction control of epoxy asphalt concrete, restrictions on the application of epoxy asphalt concrete, poor water tightness and anti-deformation ability, etc. , to achieve the effect of small porosity, good fatigue resistance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] In order to have problems in the prior art, the present invention proposes a specific implementation, including the following steps:

[0029] 1. Design of pouring asphalt concrete and epoxy asphalt concrete flexible pavement:

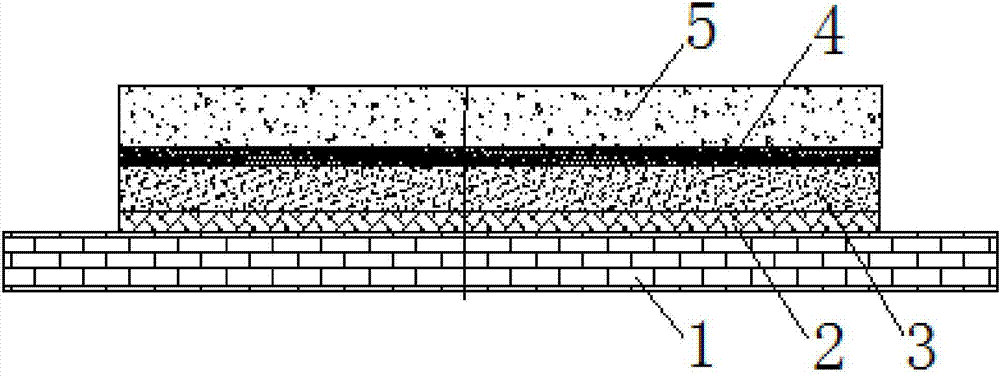

[0030] The design of poured asphalt concrete and epoxy asphalt concrete flexible pavement includes surface blasting and derusting treatment of steel box girder bridge deck, coating of waterproof adhesive layer, pouring asphalt concrete pavement underlayer (premixed gravel ), laying the interlayer adhesive layer and the paving upper layer paved with epoxy asphalt.

[0031] The pavement lower layer 3 adopts 2-3.5 cm high-temperature-resistant cast-type asphalt concrete, and the pavement upper layer 5 adopts a thin layer of 3-5 cm epoxy asphalt concrete. The pavement layer structure is as follows figure 1 shown.

[0032] The above pavement structure has the following characteristics:

[0033] 1) The lower layer adopts high temperature resistant p...

Embodiment 1

[0097] This embodiment includes the following steps:

[0098] 1. Material design of waterproof adhesive layer:

[0099] Use methyl methacrylate waterproof (MMA) bonding layer and GS-type solvent-based adhesive, the pull-out strength of the waterproof layer and the primer is 5.2Mpa, and the pull-out strength of the bond layer and the underlying layer is 2.3Mpa;

[0100] 2. Preparation of epoxy asphalt concrete:

[0101] In terms of mass ratio, the epoxy asphalt selected for epoxy asphalt concrete: aggregate: filler: fiber = 100:7:12:0.3; the main agent and curing agent in epoxy asphalt are first mixed according to the ratio of 53:47, the mixture Then mix with 70# matrix asphalt according to the ratio of 50:50; the main agent is bisphenol A epoxy, the curing agent is resin aromatic polyamine, the fiber is lignin fiber; the aggregate is basalt, and the filler is limestone powder;

[0102] When preparing epoxy asphalt, first mix base asphalt with medium material, stir at 90°C fo...

Embodiment 2

[0125] This embodiment includes the following steps:

[0126] 1. Material design of waterproof adhesive layer:

[0127] Use methyl methacrylate waterproof (MMA) bonding layer and rubber-based solvent-based adhesive, the pull-out strength of the waterproof layer and the primer is 4.8Mpa, and the pull-out strength of the bond layer and the underlying layer is 3.2Mpa;

[0128] 2. Preparation of epoxy asphalt concrete:

[0129] In terms of mass ratio, epoxy asphalt, aggregates, fillers, and fibers used in epoxy asphalt concrete = 100:8:15:0.3; the main agent and curing agent in epoxy asphalt are first mixed according to the ratio of 57:43, and the mixture Then mix with 70# matrix asphalt according to the ratio of 50:50; the main agent is bisphenol A epoxy, the curing agent is resin aromatic polyamine, the fiber is lignin fiber; the aggregate is basalt, and the filler is limestone powder;

[0130] When preparing epoxy asphalt, first mix base asphalt with medium material, stir at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com