Inner cavity enhanced photoacoustic spectrum type trace gas sensor device

A sensor device and trace gas technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of limited sensor sensitivity and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

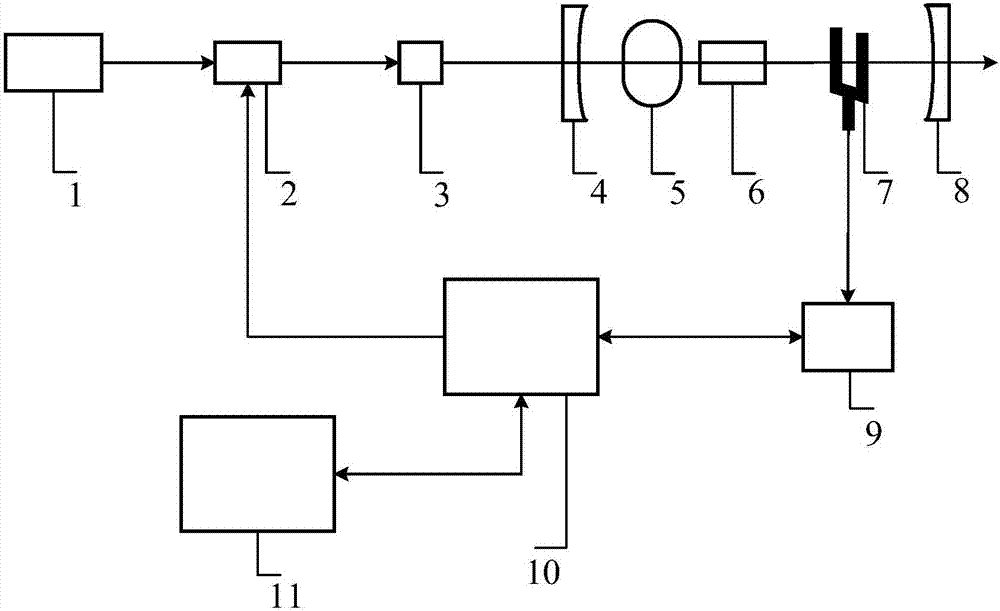

Embodiment 1

[0027] In photoacoustic spectroscopy, since the detection limit of the sensor is proportional to the laser power, the output power of the tunable laser is crucial to the detection performance of the sensor. However, as far as tunable lasers are concerned, the laser power output outside the laser resonator is on the order of mW (<50mW), and the acoustic wave detection element is placed outside the resonator, that is, the laser energy outside the cavity is used. This low power level of laser makes it difficult to further improve the detection performance of photoacoustic spectroscopy sensors, which cannot meet the application requirements in many fields.

[0028] However, the power level inside the laser resonator is much higher than outside the resonator. This is because the output coupling mirror of the laser has a certain transmittance. Taking the transmittance of 5% as an example, the laser power density inside the resonator is 19 times that outside the cavity. . Based on t...

Embodiment 2

[0038] In the present invention, the target detection gas is carbon monoxide (CO) as an example, the selected absorption wavelength is 2.33 μm, the laser resonator is placed in the CO-N2 mixed gas with a concentration of 1000ppm, and the semiconductor laser modulated by the chopper passes through the The direct focusing system is incident into the laser resonator, and the tunable filter is controlled to select an oscillating laser with a wavelength of 2.33 μm to excite CO gas to generate sound waves, and the impedance amplifier is used to amplify and extract the sound wave signal detected by the quartz tuning fork. Acoustic signal strength evaluates the performance of this inner cavity photoacoustic spectroscopy gas sensor, and the technical effect is excellent.

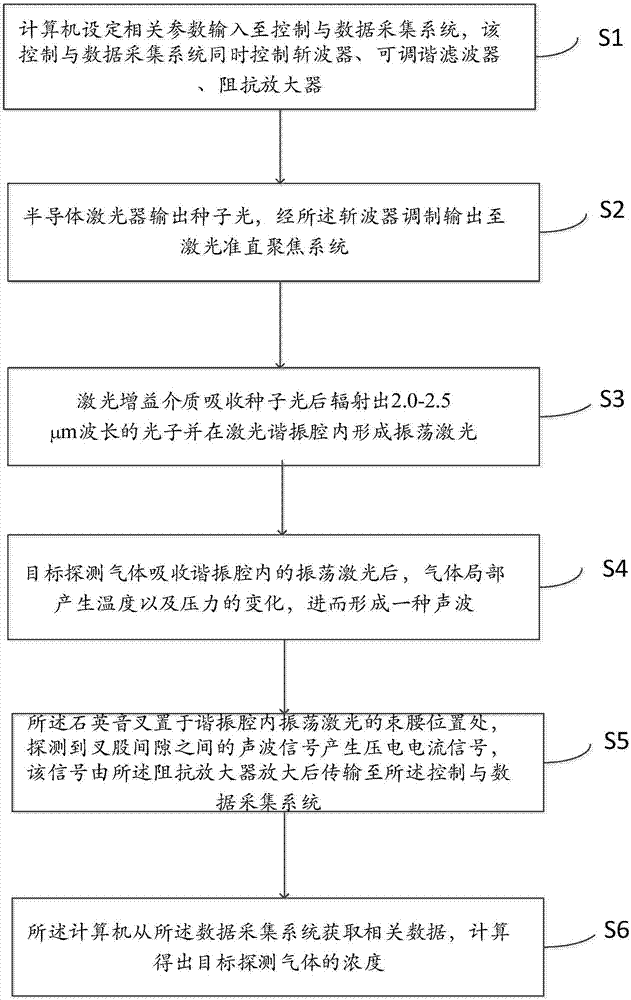

[0039] Specifically, the following steps are implemented, such as figure 2 Shown:

[0040] The relevant parameters set by the computer are input to the control and data acquisition system, and the control and data ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com