Preparation method of Nb3Al superconducting wire precursor

A technology of superconducting wires and precursors, applied in the usage of superconducting elements, superconducting/high-conducting conductors, cable/conductor manufacturing, etc., can solve the problems of magnetic flux jump, uneven structure, electromagnetic instability, etc., to avoid Magnetic flux jump, breakage prevention, effect of great commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

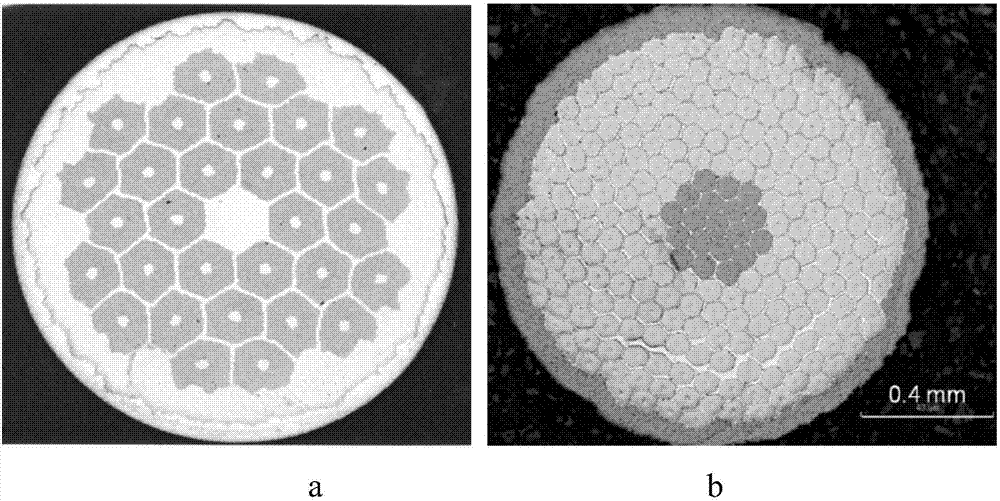

[0027] The present invention is a preparation method of a niobium tri-aluminum superconducting wire precursor. First, the Nb foil and the Al foil are superimposed and then wound on the Nb rod, and then the Cu barrier layer and the Nb protective layer are wound in turn, and then the Nb foil is extruded and processed into Nb -Al single mandrel, and then multiple Nb-Al single mandrels are put into the sheathed Cu tube, which are processed by vacuum electron beam welding and sealing, hydrostatic extrusion and drawing, and etching to remove Cu. Into the Nb-Al multi-core composite wire, that is. Specifically include the following steps:

[0028] Step 1, make Nb-Al single mandrel:

[0029] The Nb foil with a width of 100-300mm and a thickness of 0.03-0.3mm and an Al foil with a width of 100-300mm and a thickness of 0.01-0.1mm are stacked and wound on the Nb rod and packed into a Cu-coated tube. - The ratio of the thickness of Al wound on the Nb rod to the diameter of the Nb rod is ...

Embodiment 1

[0039] Step 1, making Nb-Al single mandrel

[0040] Take Cu foil, Nb foil and Al foil with a width of 100mm, wherein the thickness of Cu foil and Nb foil is 0.03mm, and the thickness of Al foil is 0.01mm. The Nb foil and Al foil are stacked and wound on a Nb rod with a diameter of 5.0mm to a diameter of 10mm, and then wrapped with a layer of Cu foil and Nb foil respectively, and placed in a Cu-coated tube with an inner diameter of 12.8mm and a wall thickness of 1.2mm , the Cu / Nb-Al composite was obtained. The Cu / Nb-Al composite was extruded into Nb-Al single mandrel rods with a pair edge distance of 1.20 mm by using a hydrostatic extrusion method at room temperature. After the Cu cladding tube on the surface of the bar was removed by etching with nitric acid, it was cut into several bars with a length of 200 mm to obtain a single core bar with a side distance of 1.0 mm and a length of 200 mm.

[0041] Step 2, pipe sealing

[0042] Fifty-four Nb-Al single mandrel rods obtain...

Embodiment 2

[0049] Step 1, making Nb-Al single mandrel

[0050] Take Cu foil, Nb foil and Al foil with a width of 200mm, wherein the thickness of Cu foil and Nb foil is 0.03mm, and the thickness of Al foil is 0.01mm. The Nb foil and Al foil are stacked and wound on a Nb rod with a diameter of 5.0mm to a diameter of 10mm, then 5 layers of Cu foil and Nb foil are wound respectively, and placed in a Cu-coated tube with an inner diameter of 10.5mm and a wall thickness of 1.0mm , the Cu / Nb-Al composite was obtained. The Cu / Nb-Al composite was extruded into Nb-Al single mandrel rods with a pair edge distance of 3.60 mm by using the room temperature hydrostatic extrusion method. After the Cu cladding tube on the surface of the bar was removed by etching with nitric acid, it was cut into several bars with a length of 200 mm to obtain a single core bar with a side distance of 3.0 mm and a length of 200 mm.

[0051] Step 2, pipe sealing

[0052] 172 Nb-Al single core rods obtained in step 1 were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com