A method for preparing a double-layer silicon nitride film on a semiconductor substrate

A double-layer silicon nitride and semiconductor technology, applied in the field of solar cells, can solve the problems of poor anti-reflection and passivation effect of single-layer silicon nitride film, large interface difference between the bottom film and top film, and increasing the proportion of reworked sheets. Achieve the effect of enhancing passivation and anti-reflection effects, improving appearance, and eliminating interface differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

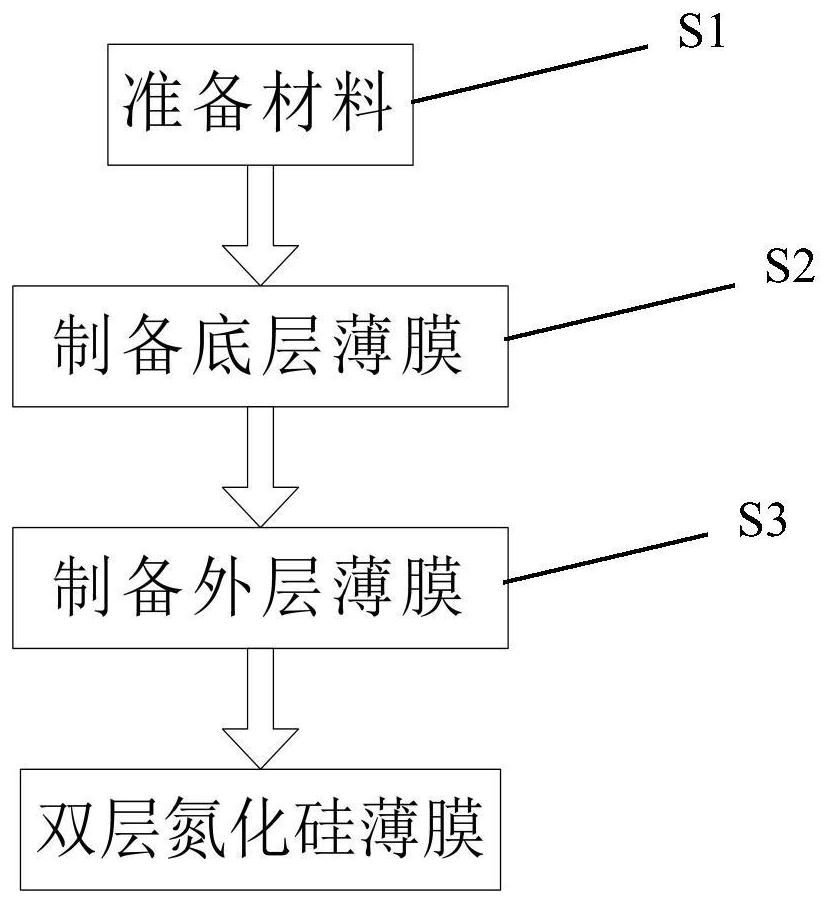

[0026] refer to Figures 1 to 2 , a method for preparing a double-layer silicon nitride film on a semiconductor substrate in this embodiment, comprising the following steps:

[0027] Step S1: Prepare materials

[0028] Prepare clean silicon wafers.

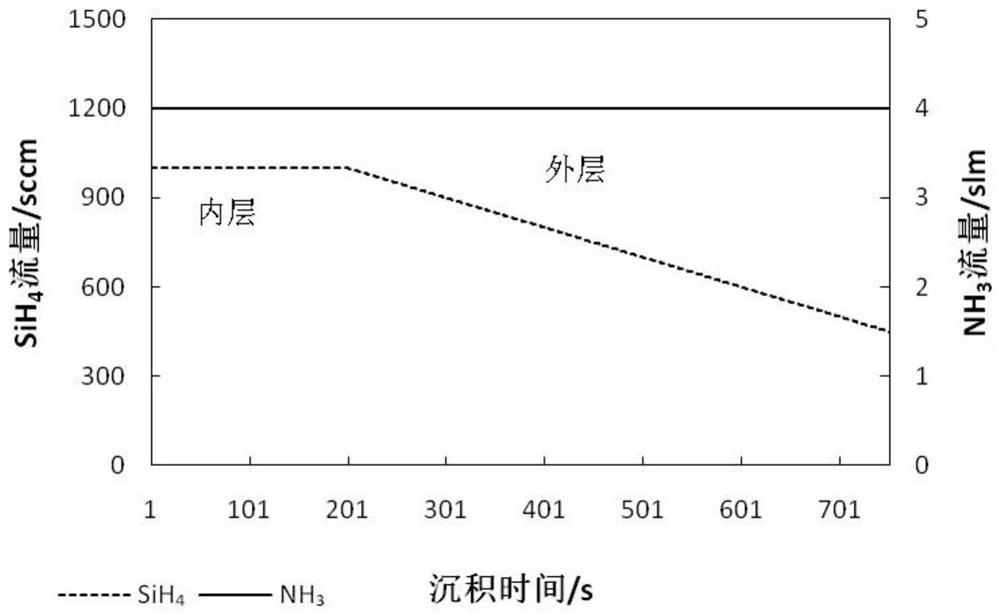

[0029] Step S2: Prepare the underlying film

[0030] Put the silicon wafer into the deposition equipment, and pass the reaction gas SiH into the deposition chamber 4 and NH 3 And by setting the first deposition condition, the underlying silicon nitride film is deposited on the silicon wafer.

[0031] The first deposition condition is: deposition power is 6000W, pressure is 1500mTorr, time is 200s, NH 3 flow rate of 4 slm, SiH 4 The flow rate is 1000sccm. Control NH 3 and SiH 4 The flow rate is fixed and a certain thickness of the underlying film is deposited to ensure the passivation effect of the underlying film.

[0032] Step S3: Prepare the outer film

[0033] Continue to feed reaction gas SiH in the deposition chamb...

Embodiment 2

[0036] refer to figure 1 with image 3 , a method for preparing a double-layer silicon nitride film on a semiconductor substrate in this embodiment, comprising the following steps:

[0037] Step S1: Prepare materials

[0038] Prepare clean silicon wafers.

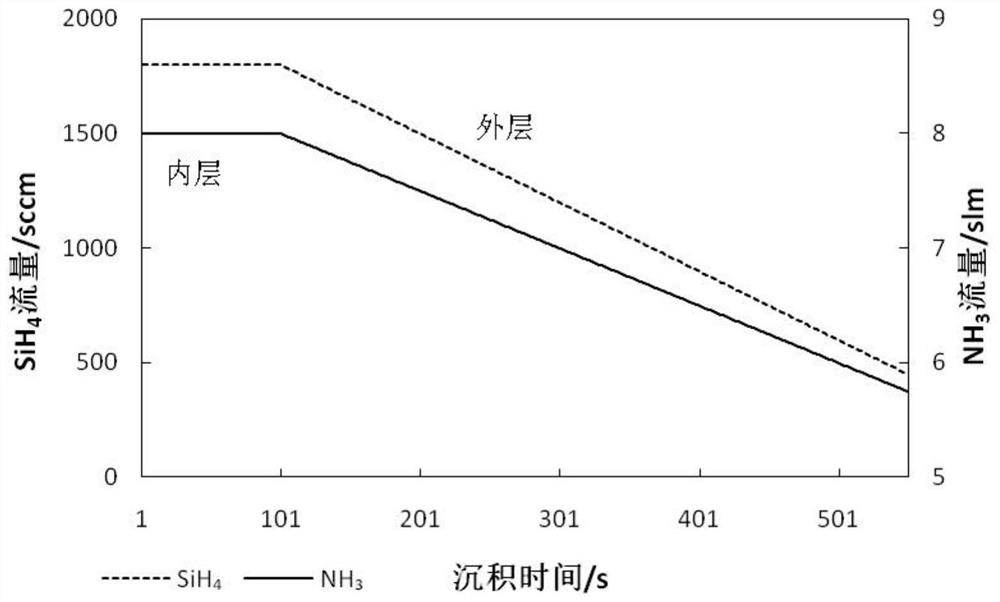

[0039] Step S2: Prepare the underlying film

[0040] Put the silicon wafer into the deposition equipment, and pass the reaction gas SiH into the deposition chamber 4 and NH 3 And by setting the first deposition condition, the underlying silicon nitride film is deposited on the silicon wafer.

[0041] The first deposition condition is: deposition power is 8000W, pressure is 2000mTorr, time is 100s, NH 3 flow rate of 8 slm, SiH 4 The flow rate is 1800sccm. Control reaction gas NH 3 and SiH 4 The flow rate is fixed and a certain thickness of the underlying film is deposited to ensure the passivation effect of the underlying film.

[0042] Step S3: Prepare the outer film

[0043] Continue to feed reaction gas SiH in...

Embodiment 3

[0046] refer to figure 1 with Figure 4 , a method for preparing a double-layer silicon nitride film on a semiconductor substrate in this embodiment, comprising the following steps:

[0047] Step S1: Prepare materials

[0048] Prepare clean silicon wafers.

[0049] Step S2: Prepare the underlying film

[0050] Put the silicon wafer into the deposition equipment, and pass the reaction gas SiH into the deposition chamber 4 and NH 3 And by setting the first deposition condition, the underlying silicon nitride film is deposited on the silicon wafer.

[0051] The first deposition condition is: deposition power is 7000W, pressure is 1700mTorr, time is 100s, NH 3 flow rate of 5 slm, SiH 4 The flow rate is 1000sccm. Control NH 3 and SiH 4 The flow rate is fixed and a certain thickness of the underlying film is deposited to ensure the passivation effect of the underlying film.

[0052] Step S3: Prepare the outer film

[0053] Continue to feed SiH in the deposition chamber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com