Isobutane dehydrogenation catalyst, preparation method and dehydrogenation technology of isobutane dehydrogenation catalyst

A dehydrogenation catalyst, isobutane technology, applied in catalyst activation/preparation, catalyst, carbon compound catalyst, etc., can solve the problems of short service cycle, low catalyst stability, affecting production efficiency, etc., achieve high conversion rate, improve Activity and selectivity, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

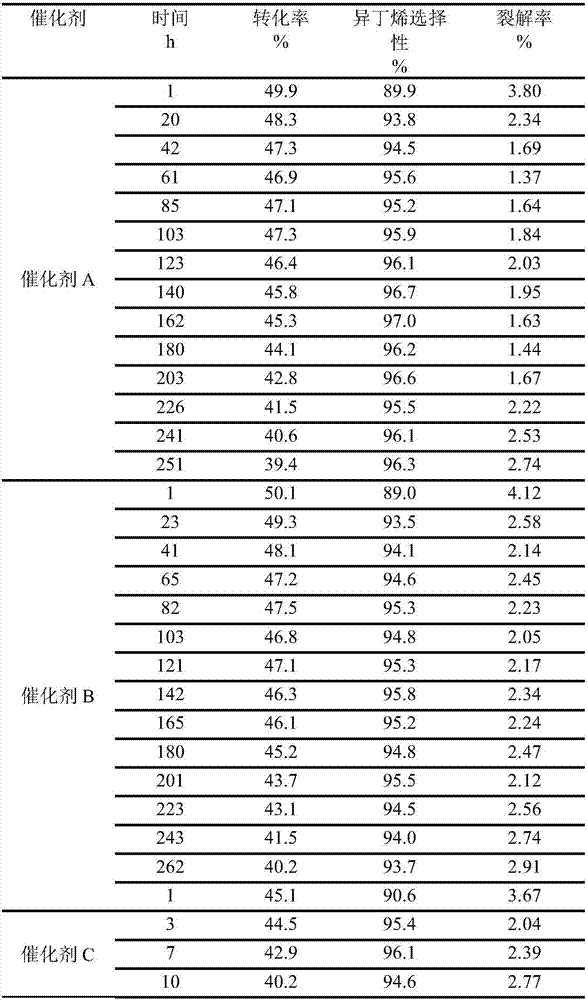

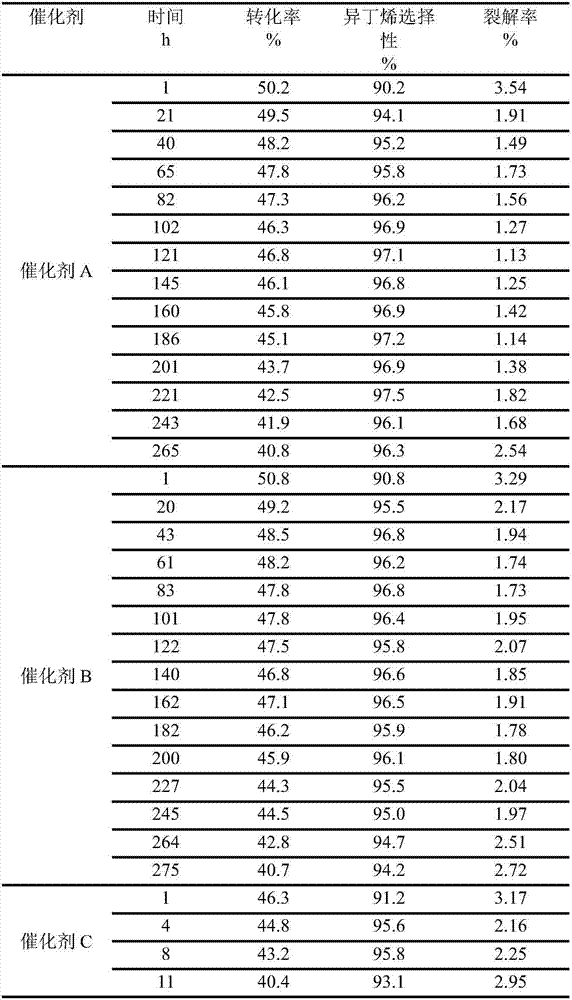

Examples

Embodiment 1

[0029] (1) Take a certain amount of formed alumina carrier and put it into the impregnation equipment;

[0030] (2) Take a certain amount of chloroplatinic acid H 2 PtCl 6 (calculated as 0.15% Pt), dissolved with an appropriate amount of dilute hydrochloric acid, added to the carrier, impregnated under negative pressure -0.07MPa for 1 hour, then dried at 110°C for 10 hours, and calcined at 500°C for 4 hours in air atmosphere ;

[0031] (3) Weigh an appropriate amount of tin tetrachloride SnCl 4 (calculated as 0.35% Sn), after dissolving with an appropriate amount of deionized water, add the carrier obtained in step (2), dip for 1 hour under negative pressure -0.07MPa, then dry at 110°C for 10 hours, Baking at 500°C for 4 hours;

[0032] (4) Weigh an appropriate amount of potassium chloride (in terms of 0.5% K), dissolve it with an appropriate amount of deionized water, add the carrier obtained in step (3), and immerse it for 1 hour under a negative pressure of -0.07MPa, th...

Embodiment 2

[0036] (1) Take a certain amount of formed alumina carrier and put it into the impregnation equipment;

[0037] (2) Take a certain amount of chloroplatinic acid H 2 PtCl 6 (calculated as 0.08% Pt), dissolved with an appropriate amount of dilute hydrochloric acid, added to the carrier, impregnated under negative pressure -0.04MPa for 1 hour, then dried at 110°C for 10 hours, and calcined at 500°C for 2 hours in air atmosphere ;

[0038] (3) Weigh an appropriate amount of tin tetrachloride SnCl 4 (calculated as 0.3% Sn), after dissolving with an appropriate amount of deionized water, add the carrier obtained in step (2), soak for 1 hour under negative pressure -0.04MPa, then dry at 110°C for 10 hours, and Baking at 500°C for 2 hours;

[0039](4) Weigh an appropriate amount of potassium chloride (in terms of 0.3% K), dissolve it with an appropriate amount of deionized water, add the carrier obtained in step (3), and immerse it for 1 hour under a negative pressure of -0.04MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com