An active filter material for manganese removal by catalytic oxidation in a water purification plant and its preparation method

A technology for catalytic oxidation and water purification plants, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. The preparation speed is fast, the preparation method is simple, and the preparation cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

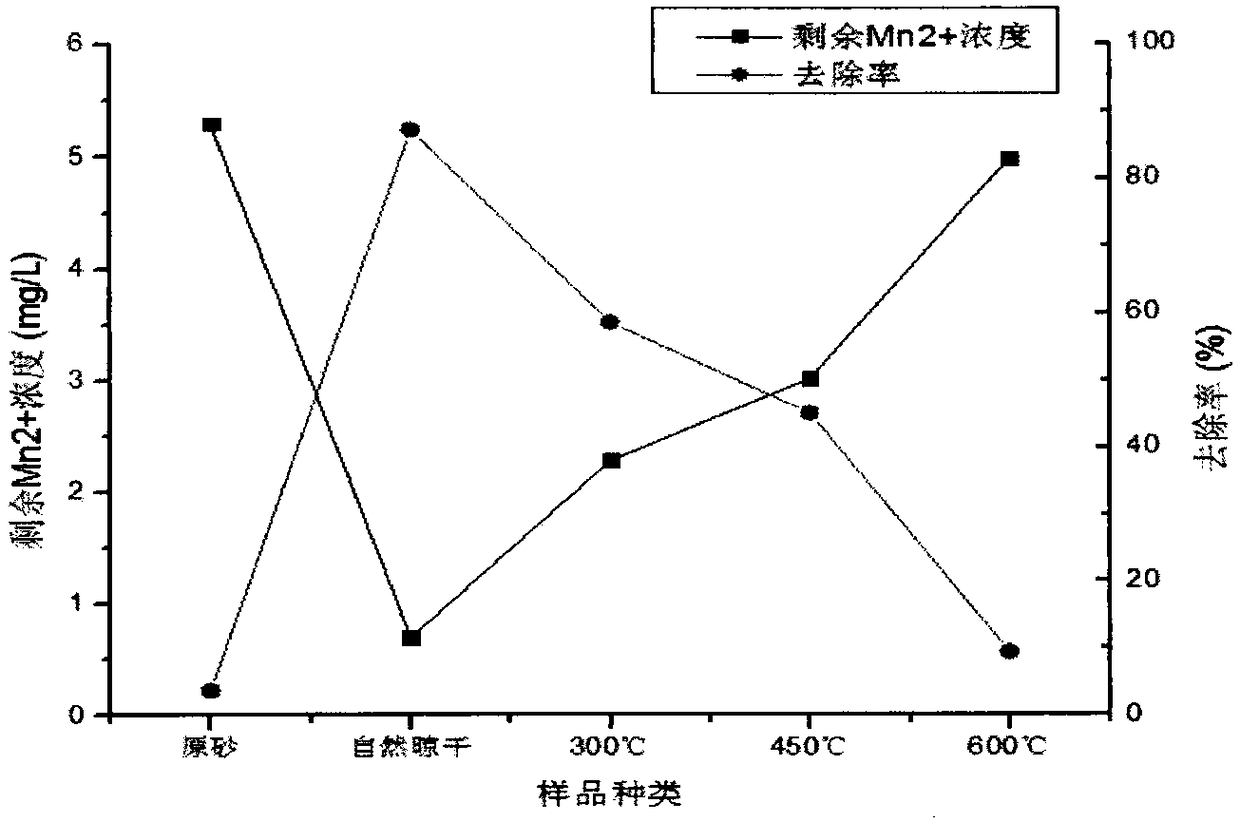

[0031] This embodiment provides an active filter material for manganese removal by catalytic oxidation in a water purification plant and a preparation method thereof, comprising the following steps:

[0032] (1) Acid etching: the particle size is d 10 =Coarse quartz sand of 0.9-1.2 mm is used as a raw material, and the quartz sand is soaked with 7.3% HCl for 48 hours for acid etching, taken out, and drained;

[0033] (2) Alkaline etching: the quartz sand after the treatment of step (1) is washed several times with a mass ratio of 1% NaOH solution, then soaked for 24 hours with a mass ratio of 4% NaOH solution, then the quartz sand is taken out, After washing with distilled water, draining or drying, place it in a muffle furnace, calcinate at 600°C for 2 hours in an air atmosphere, and cool naturally;

[0034] (3) Submerge the treated quartz sand in step (2) in MnSO with a concentration of 0.15mol / L 4 In the solution, soak for 2 hours, and keep stirring slowly during the soak...

Embodiment 2

[0039] This embodiment provides an active filter material for manganese removal by catalytic oxidation in a water purification plant and a preparation method thereof, comprising the following steps:

[0040] (1) Take 5kg of quartz sand and put it in a plastic bucket, its d 10 =0.9-1.2mm, immerse the quartz sand with 7.3% HCl solution for 48 hours, the HCl solution just submerges the quartz sand, after acid etching, take out the quartz sand and drain the liquid.

[0041] (2) washing the quartz sand after step (1) with a mass ratio of 1% NaOH solution for several times, and then immersing it in a 4% NaOH solution for 24 hours, the NaOH solution just submerged the quartz sand, after the immersion finished, Wash with distilled water several times, dry, and then calcined at 600°C for 2 hours, and cool naturally.

[0042] (3) Accurately add MnSO with a concentration of 0.15mol / L 4 1325ml of the solution is submerged in the quartz sand, soaked for 2 hours, and continuously stirred ...

Embodiment 3

[0050] This embodiment provides an active filter material for manganese removal by catalytic oxidation in a water purification plant and a preparation method thereof, comprising the following steps:

[0051] (1) Take 5kg of quartz sand and put it in a plastic bucket, its d 10 =0.9-1.2mm, immerse the quartz sand with 7.3% HCl solution for 48 hours, the HCl solution just submerges the quartz sand, after acid etching, take out the quartz sand and drain the liquid;

[0052] (2) washing the quartz sand after step (1) with a mass ratio of 1% NaOH solution for several times, and then immersing it in a 4% NaOH solution for 24 hours, the NaOH solution just submerged the quartz sand, after the immersion finished, Wash with distilled water several times, dry, and then calcined at 600°C for 2 hours, and cool naturally.

[0053] (3) Accurately add MnSO with a concentration of 0.15mol / L 4 1325ml of the solution is submerged in the quartz sand, soaked for 2 hours, and continuously stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com