Methods for improving efficiency of simultaneous saccharification and fermentation reactions

A technology for synchronous saccharification and fermentation and fermentation products, which is applied in the direction of using microorganisms, biochemical equipment and methods, fermentation, etc., and can solve problems such as lengthy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

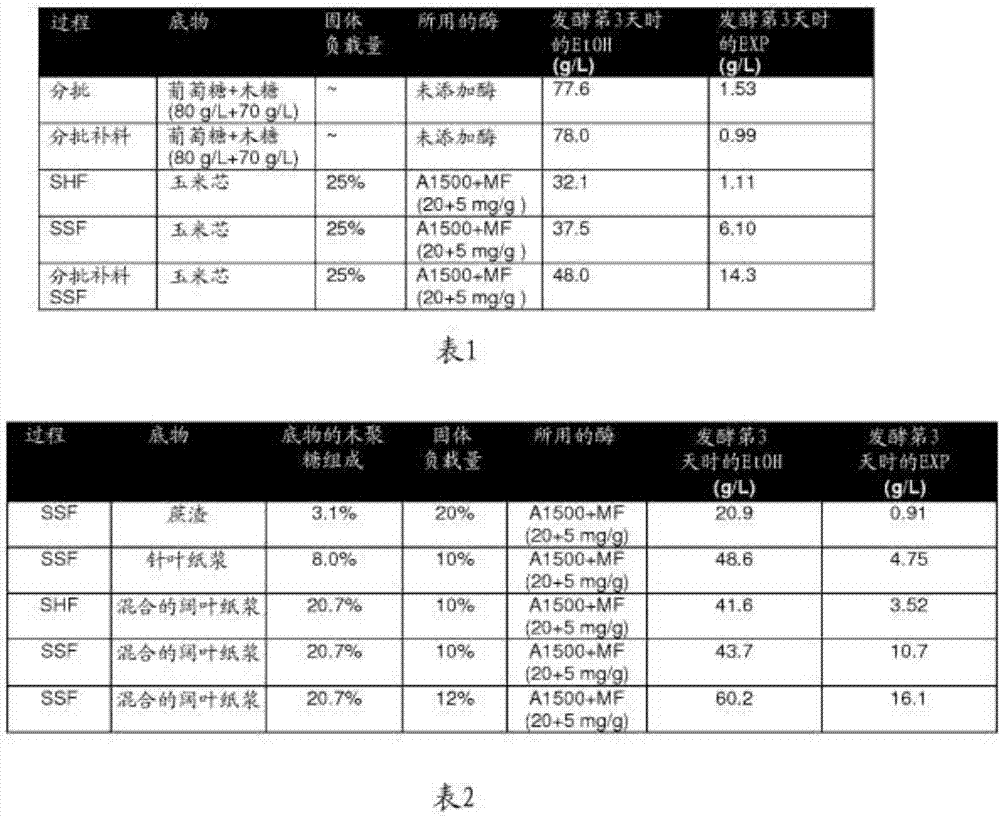

[0333] 7. Example 1: Analysis of Exp formation in SSF reactions

[0334] 7.1. Materials and methods

[0335] 7.1.1. Substrates

[0336] The substrates used in this work are listed below. The cellulose, xylan and lignin components of the pretreated substrates are also listed. Composition analysis utilized the standards detailed in "NREL protocols for Standard Biomass Analytical Procedures" (available at http: / / www.nrel.gov / biomass / pdfs / 42618.pdf) Assay performed:

[0337] Corn cob pretreated with dilute ammonia water . Corn cobs are pretreated prior to enzymatic hydrolysis according to, for example, U.S. Patent Application Publication Nos. The methods and processing scope described in patent application publication WO06 / 110901A2 were carried out (unless otherwise indicated).

[0338] The composition of the substrate includes : 34.8% cellulose, 29.2% xylan, 12.8% lignin.

[0339] Bagasse pretreated with dilute sulfuric acid . This substrate is produced and su...

example 2

[0401] 8. Example 2: Hemicellulase leads to reduction of exp

[0402] The following example demonstrates that the addition of certain hemicellulases reduces EXP in SSF reactions.

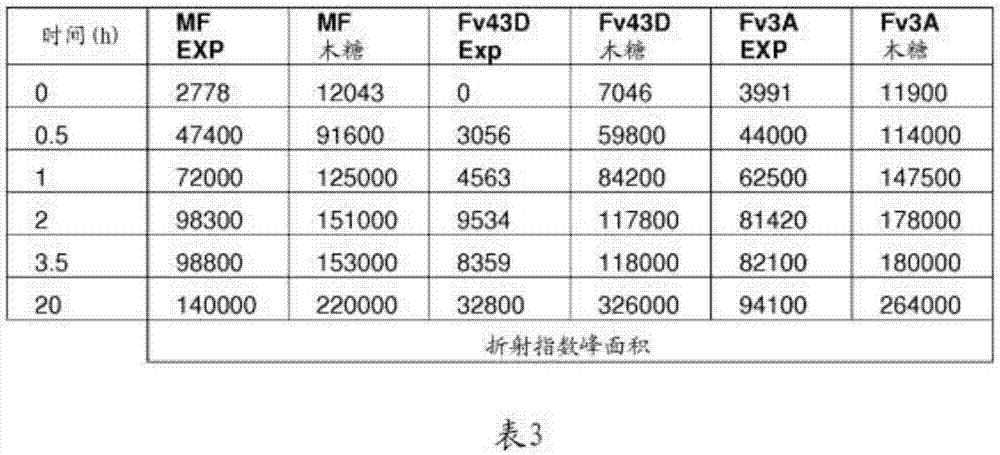

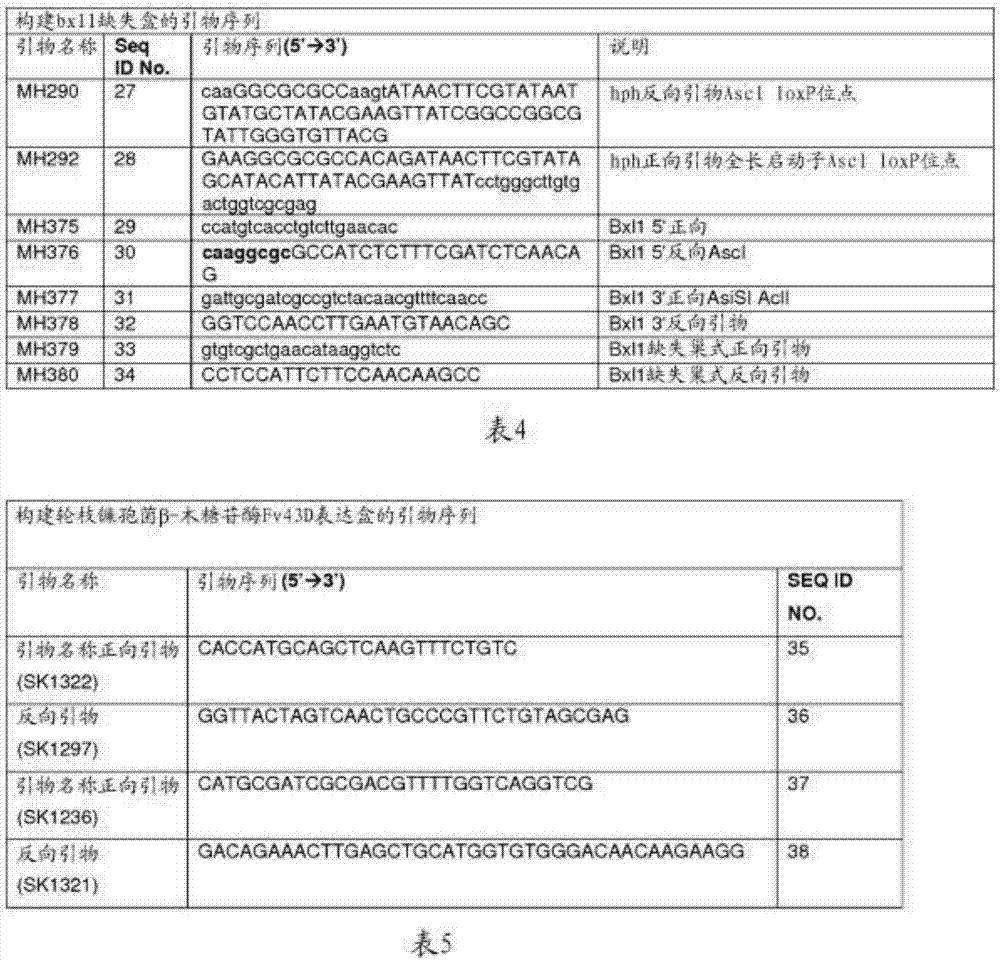

[0403] 8.1. Fv43D leads to reduced EXP in Zymomonas SSF

[0404] EXP formation typically consumes xylose (either directly, or from xylobiose or other xylo-oligomers) and ethanol in an equimolar ratio. This consumption mechanism directly leads to significantly reduced ethanol production because many microorganisms, including Zymomonas, are unable to degrade, ferment, or otherwise utilize EXP. One (1) gram of EXP was calculated to be equivalent to a loss of 0.688 g of ethanol produced (assuming xylose was fermented to ethanol at a rate of 0.51 g / g xylose). Thus, preventing the formation of EXP can lead to a consequent increase in ethanol production. have been found, such as Figure 10 It was shown that addition of the Fusarium verticillium beta-xylosidase Fv43D at an amount of only 1 mg / g xyla...

example 3

[0418] 9. Example 3: EXP formation mechanism

[0419] Under SSF conditions ( Figure 10 and 11 ), the EXP production in the presence of Verticillium β-xylosidase Fv3A was approximately 4-fold higher than in the presence of Verticillium β-xylosidase Fv43D, such observations inspired Efforts have been made to understand the mechanism of EXP formation.

[0420] There are potentially two possible pathways for EXP formation: (1) by transglycosylation; or (2) by reverse hydrolysis. Each of these pathways is described below:

[0421] 1) Transglycosylation: X-O-X+EtOH→X-O-Et+X

[0422] 2) reverse hydrolysis:

[0423] According to Drouet et al. (1994, Biotech. & Bioeng. 43: 1075-1080), the transglycosylation mechanism is the more rapid of the two. Only the β-anomer is formed in the transglycosylation reaction (see Figure 29 ) implies that the reaction is catalyzed by an enzyme that acts on the substrate in a way that maintains the anomeric configuration, where the sugars ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com