Method for preparing 5N cobalt chloride through P507 fractional extraction

A cobalt chloride and extraction technology, which is applied in the field of directly preparing 5N-level cobalt chloride, can solve the problems of small processing capacity, the 5N-level cobalt chloride solvent extraction method has not been established, and the purification cost is high, and the production cost is reduced, which is beneficial to large Large-scale industrial production and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

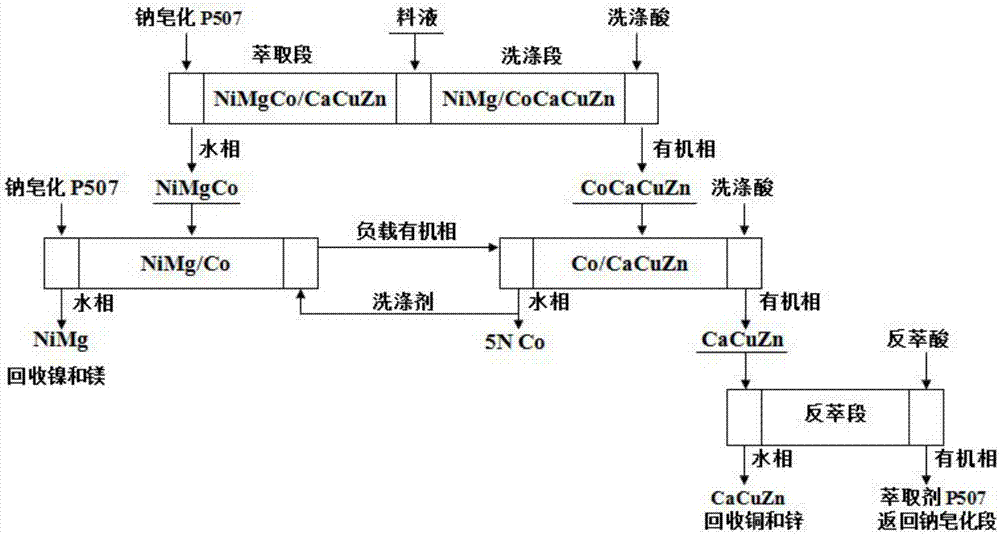

[0025] 1) Separation of NiMgCo / CoCaCuZn by fractional distillation and extraction

[0026]The organic phase of sodium saponification P507 is the sulfonated kerosene solution of extraction agent P507, the concentration of extraction agent P507 is 1.0mol / L; sodium saponification must be carried out during use, and the saponification rate is 36%. The high-cobalt and low-nickel industrial hydrochloride solution is an aqueous solution containing cobalt chloride as the feed liquid, and its composition is: Co 70.0g / L, Ni 2.0g / L, Mg 5.0g / L, Ca 2.0g / L, Cu 1.5 g / L, Zn 1.5g / L, pH=4. The washing acid is 3.0mol / L HCl.

[0027] The organic phase of sodium saponification P507 enters the NiMgCo / CoCaCuZn fractionation extraction system from the first stage, the high-cobalt and low-nickel industrial hydrochloride solution enters the NiMgCo / CoCaCuZn fractionation extraction system from the 17th stage, and the 3.0mol / L HCl washing acid enters from the 28th stage NiMgCo / CoCaCuZn Fractional Extra...

Embodiment 2

[0036] 1) Separation of NiMgCo / CoCaCuZn by fractional distillation and extraction

[0037] The organic phase of sodium saponification P507 is sulfonated kerosene solution of extraction agent P507, the concentration of extraction agent P507 is 1.5mol / L; sodium saponification must be carried out during use, and the saponification rate is 30%. High-cobalt and low-nickel industrial hydrochloride solution is an aqueous solution containing cobalt chloride as the feed liquid, and its composition is: Co 90.0g / L, Ni 3.0g / L, Mg 8.0g / L, Ca 3.0g / L, Cu 2.0 g / L, Zn 2.0 g / L, pH=3. The washing acid is 3.0mol / L HCl.

[0038] The organic phase of sodium saponification P507 enters the NiMgCo / CoCaCuZn fractionation extraction system from the first stage, the high-cobalt and low-nickel industrial hydrochloride solution enters the NiMgCo / CoCaCuZn fractionation extraction system from the 17th stage, and the 3.0mol / L HCl washing acid enters from the 28th stage NiMgCo / CoCaCuZn Fractional Extraction ...

Embodiment 3

[0047] 1) Separation of NiMgCo / CoCaCuZn by fractional distillation and extraction

[0048] The organic phase of sodium saponification P507 is sulfonated kerosene solution of extraction agent P507, the concentration of extraction agent P507 is 0.5mol / L; sodium saponification must be carried out during use, and the saponification rate is 40%. The high-cobalt and low-nickel industrial hydrochloride solution is an aqueous solution containing cobalt chloride as the feed liquid, and its composition is: Co 50.0g / L, Ni 1.0g / L, Mg 2.0g / L, Ca 1.0g / L, Cu 1.0 g / L, Zn 1.0 g / L, pH=5. The washing acid is 3.0mol / L HCl.

[0049] The organic phase of sodium saponification P507 enters the NiMgCo / CoCaCuZn fractionation extraction system from the first stage, the high-cobalt and low-nickel industrial hydrochloride solution enters the NiMgCo / CoCaCuZn fractionation extraction system from the 16th stage, and the 3.0mol / L HCl washing acid enters from the 27th stage NiMgCo / CoCaCuZn Fractional Extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com