Nickel-free environment-friendly electroplating process

An electroplating process and environmental protection technology, applied in the field of nickel-free environmental protection electroplating process, can solve problems such as unfavorable market and export business expansion, and achieve the effect of low toxicity and environmental protection in the process, mild conditions, and reduction of cumbersome processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

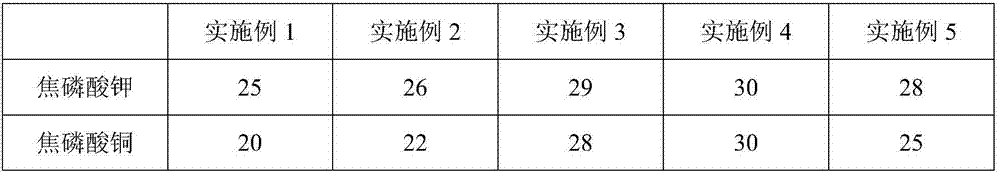

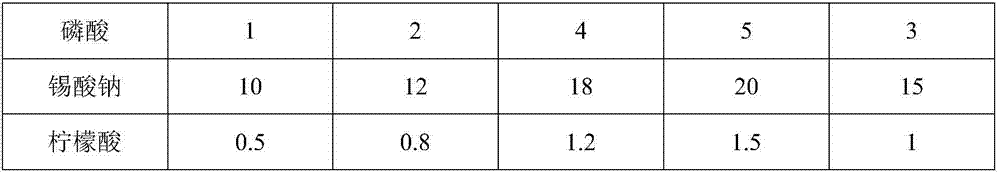

Examples

Embodiment 1

[0024] A nickel-free environmental protection electroplating process described in this embodiment comprises the following method steps:

[0025] 1) Pre-treatment: Wipe the surface of the plastic structural parts with absolute ethanol, then put it into the plasma generator to evacuate and inject the mixed gas for surface plasma treatment, wash with water after the plasma treatment, the vacuum degree of the plasma treatment process is 30-100Pa, mix Gas flow rate is 120-180sccm, plasma generator power supply parameters: high frequency power supply 40KHz, radio frequency power supply 13.56MHz, plasma treatment time is 30s-15min;

[0026] 2) Pre-soaking treatment: the pre-treated plastic structural parts are sent to the pre-soaking tank for pre-soaking, and after pre-soaking, they are put into the cleaning tank and cleaned with deionized water. The pre-soaking liquid in the pre-soaking tank is 15-25g / L Aqueous stannous chloride solution, the pre-soaking treatment time is 1-3min;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com