Method for preparing polyacid/macromolecule hybrid nanofiber membrane by using electrospinning method

An electrospinning method and nanofiber membrane technology, which is applied in the field of preparation of polymer-based polyacid-loaded hybrid nanofiber membranes, can solve the problems of slow sewage treatment rate, inability to large-scale production, unstable material properties, and the like. Dimensional stability, fast and efficient reduction and removal, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of tungstopolyacid / PAN hybrid nanofiber membrane, comprising steps as follows:

[0055] (1) Preparation of spinning solution

[0056] Add 0.5 g of polyacrylonitrile (PAN) particles to 6 mL of N,N-dimethylformamide (DMF), stir until the polyacrylonitrile is completely dissolved, then add 2 g of WCl 6 , stirred to WCl 6 Dissolve completely to obtain orange-red clear spinning solution;

[0057] (2) Electrospinning

[0058] Use the electrospinning equipment model ss-2535H of Beijing Yongkang Leye Co., Ltd. to carry out electrospinning, pour the spinning solution prepared in step (1) into the syringe, and use the rotating drum receiving plate for spinning; electrospinning The conditions are: voltage 15kV, electrode distance 170mm, temperature 20°C, relative humidity 30%, propulsion pump speed 0.08ml / min, to obtain the nanofiber membrane precursor;

[0059] (3) Precursor reduction

[0060] Put the nanofiber film precursor obtained in step (2) into an...

Embodiment 2

[0065] As described in Example 1, the difference is:

[0066] WCl in step (1) 6 The addition amount is 1g;

[0067] Step (2) is with embodiment 1;

[0068] Step (3) is the same as in Example 1.

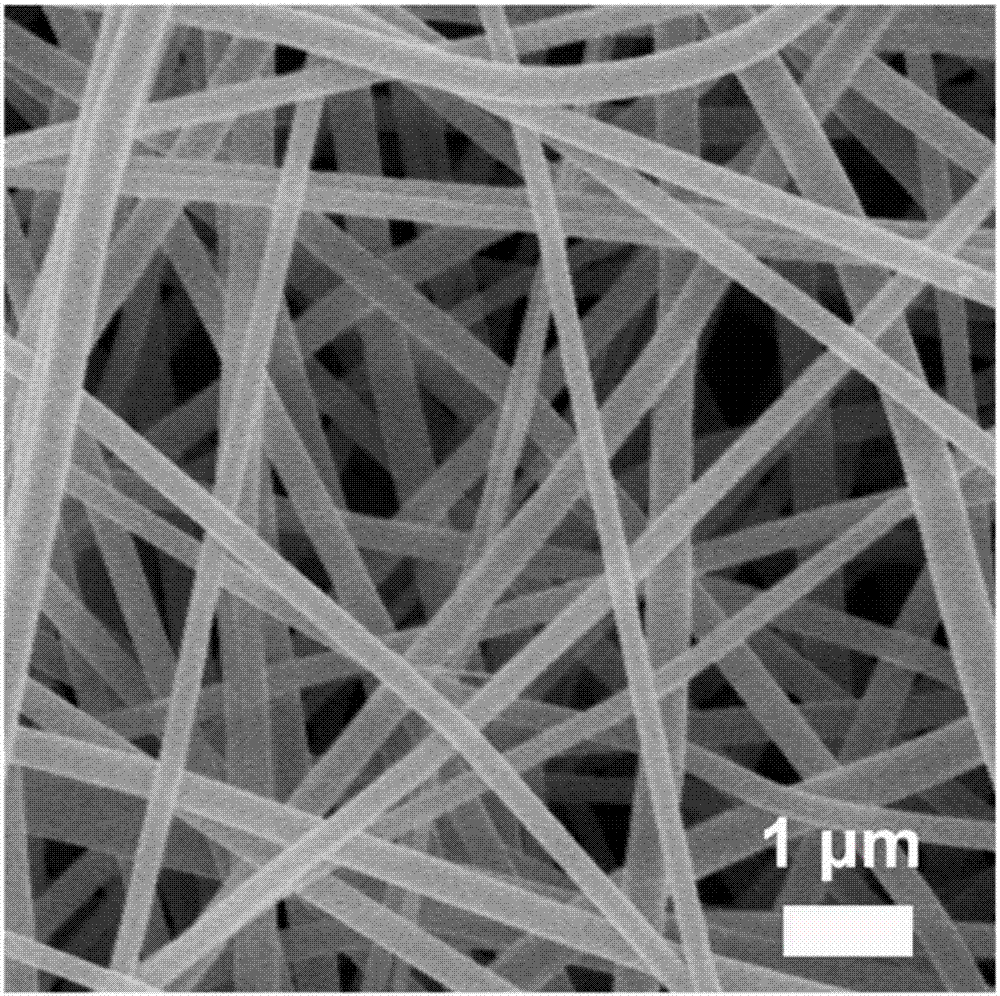

[0069] The SEM photos of the obtained tungstic acid / PAN hybrid nanofibers of the present embodiment are as follows figure 2 shown by figure 2 It can be seen that the diameter of tungstopolyacid / PAN hybrid nanofibers is uniform, and the average diameter is about 200nm.

Embodiment 3

[0088] A preparation method of tungstopolyacid / PVP hybrid nanofiber membrane, comprising steps as follows:

[0089] (1) Preparation of spinning solution

[0090] Add 0.4 g of polyvinylpyrrolidone (PVP) particles into 5 mL of N,N-dimethylformamide (DMF), stir until the polyacrylonitrile is completely dissolved, then add 0.5 g of WCl 6 , stirred to WCl 6 Dissolve completely to obtain blue-green clear spinning solution;

[0091] (2) Electrospinning

[0092] Use the electrospinning equipment model ss-2535H of Beijing Yongkang Leye Co., Ltd. to carry out electrospinning, pour the spinning solution prepared in step (1) into the syringe, and use the rotating drum receiving plate for spinning; electrospinning The conditions are: voltage 15kV, electrode distance 170mm, temperature 30°C, relative humidity 20%, propulsion pump speed 0.08mL / min, to obtain the nanofiber membrane precursor;

[0093] (3) Precursor reduction

[0094] Put the nanofiber film precursor obtained in step (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com