A papermaking method using waste tea stems as raw materials

A technology for tea stalks and raw materials, which is applied in the field of papermaking using waste tea stalks as raw materials, can solve the problems of shortage and low quality, and achieve the effects of high paper strength, fine fiber distribution and good interweaving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

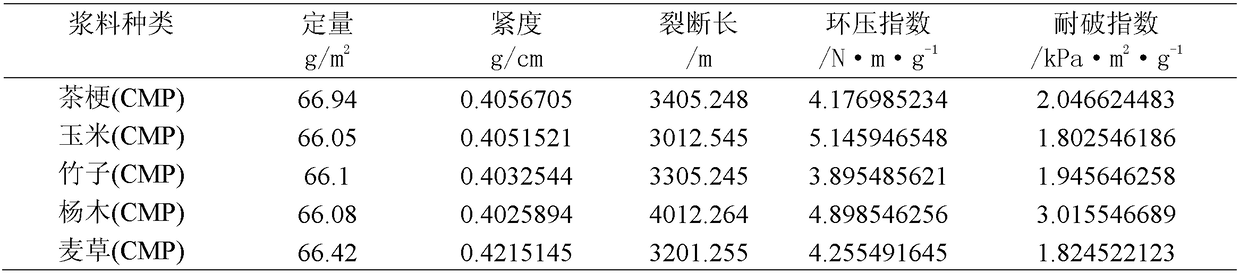

Image

Examples

Embodiment 1

[0021] The papermaking method of the present invention is that waste tea stalk is raw material, concrete steps are as follows:

[0022] Step 1. Preprocessing

[0023] Select tea stems for washing, drying, chopping and dedusting;

[0024] Step 2. Cooking and pressing

[0025] The tea stem in step 1 is passed through a water solvent (liquid-to-material mass ratio 40:1), and extracted at a temperature of 80°C for 35 minutes to obtain the tea polyphenols therein, which is then used; then NaOH and anthraquinone, NaOH are added to the tea stem The dosage is 20%, the dosage of anthraquinone is 3‰, and the liquid ratio is 1:3. (the amount of sodium hydroxide and anthraquinone is relative to the quality of the dry tea stalks, and the liquid ratio is the quality of the dry tea stalks: the quality of water). After fully stirring and mixing evenly, steaming is carried out, and then the cooking waste liquid is separated by dehydration and pressing to obtain Coarse slurry (through this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com