Preparation method of mulberry twig granular biofuel

A biofuel, mulberry technology, applied in the directions of biofuels, waste fuels, fuels, etc., can solve the problems of high combustion value of mulberry branch granule biofuel, ineffective utilization of mulberry branches, and increase farmers' income, etc., to achieve excellent combustion characteristics, increase Farmers' income, the effect of strong reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

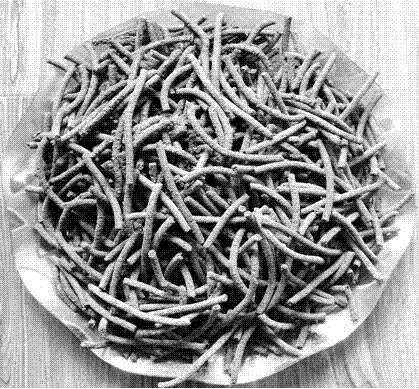

Image

Examples

Embodiment 1

[0035] Utilize the mulberry branches cut after the end of silkworm rearing in spring, carry out primary drying through natural sunlight, collect the primary dried mulberry branches and grind them with a pulverizer until the particle size is below 3mm to obtain mulberry branch powder, and mulberry branch powder Sun-dried to a moisture content of less than 15%. Mulberry branch powder 93 wt% and river mud powder 7wt% are mixed evenly to obtain mixed powder, the particle size of river mud powder is below 3mm, and the water content of river mud powder is about 12%.

[0036] The mixed powder is compression-molded by a molding machine to obtain pellets (the mixed powder is suitable for various pellet fuel molding machines in the current market to produce pellet fuel), the temperature of the compression molding is controlled at 180°C, the pressure is 12MPa, and the particle diameter is 0.8 About cm, the length can be adjusted according to the use of fuel.

[0037] Taking a particle w...

Embodiment 2

[0041] Utilize the mulberry branches cut after the end of silkworm rearing in spring, carry out primary drying through natural sunlight, collect the primary dried mulberry branches and grind them with a pulverizer until the particle size is below 3mm to obtain mulberry branch powder, and mulberry branch powder Sun-dried to a moisture content of less than 15%. Mulberry branch powder 95 wt% is mixed with river mud powder 5wt% evenly to obtain mixed powder, the particle size of river mud powder is below 3mm, and the water content of river mud powder is about 10%.

[0042] The mixed powder is molded by a molding machine to obtain granules. The temperature of the mold is controlled at 200°C, the pressure is 15MPa, the diameter of the particles is about 0.8cm, and the length can be adjusted according to the purpose of the fuel.

[0043] Taking a particle with a length of 2cm as an example, its industrial indicators and combustion characteristic parameters are as follows:

[0044]Mo...

Embodiment 3

[0047] After falling leaves in winter, use the weak and small residual branches obtained by pruning mulberry branches in winter and pruning mulberry trees as raw materials for mulberry branches, and carry out primary drying through natural sunlight, and collect the primary dried mulberry branches and grind them with a pulverizer until the particle size is 3mm. The mulberry branch powder is obtained as follows, and the mulberry branch powder is dried in the sun until the moisture content is within 15%. Mulberry branch powder 92 wt % and river mud powder 8wt% are mixed evenly to obtain mixed powder, the particle size of river mud powder is below 3 mm, and the water content of river mud powder is about 15%.

[0048] The mixed powder is molded by a molding machine to obtain granules. The temperature of the mold is controlled at 150°C, the pressure is 10MPa, the diameter of the particles is about 0.8cm, and the length can be adjusted according to the purpose of the fuel.

[0049] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com