Preparation method of lithium-sulfur battery negative electrode biological carbon material

A technology of bio-carbon materials and lithium-sulfur batteries, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of poor electrode cycle stability, prevent long-term cycle stability of lithium-sulfur batteries, and reduce energy density. Achieve the effect of improving the degree of graphitization and electrical conductivity, rich in internal cellulose content, and conducive to complete penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

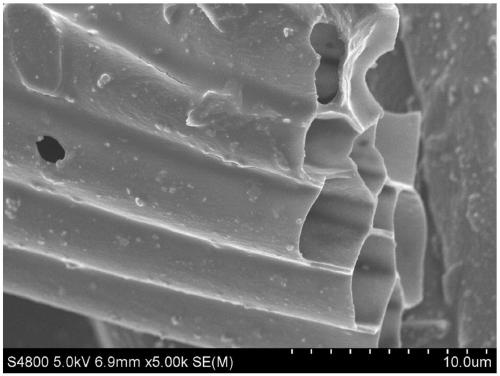

Image

Examples

Embodiment 1

[0029] 1) Take 2g of dandelion and wash with distilled water and dry to obtain product A;

[0030] 2) Add 100mL of water to product A, then add 10mL of concentrated sulfuric acid, concentrated hydrochloric acid and concentrated nitric acid at a volume ratio of 6:2:2, stir with a glass rod for 10 minutes to fully react, and obtain solution B;

[0031] 3) Dilute solution B to pH=7, filter and dry to obtain product C;

[0032] 4) Add 1 mL of concentrated sulfuric acid and 49 mL of water to product C, place it in a hydrothermal reaction kettle at 160°C, and react for 30 hours to obtain solution D;

[0033] 5) Dilute solution D to pH=7, filter, and dry to obtain product E;

[0034] 6) Spread the product E on a white alumina porcelain boat, spread a layer of conductive graphite evenly on it, and place it in a tube furnace with an argon atmosphere from room temperature to 1000 °C at a heating rate of 5 °C / min. °C, reacted at 1000 °C for 10 h to obtain product F, wherein the argon f...

Embodiment 2

[0039] 1) Take 8g of dandelion and wash with distilled water and dry to obtain product A;

[0040] 2) Add 100mL of water to product A, then add 60mL of concentrated sulfuric acid, concentrated hydrochloric acid and concentrated nitric acid at a volume ratio of 6:2:2, stir with a glass rod for 10 minutes to fully react, and obtain solution B;

[0041] 3) Dilute solution B to pH=7, filter and dry to obtain product C;

[0042] 4) Add 5 mL of concentrated sulfuric acid and 45 mL of water to product C, place it in a hydrothermal reaction kettle at 180°C, and react for 24 hours to obtain solution D;

[0043] 5) Dilute solution D to pH=7, filter, and dry to obtain product E;

[0044] 6) Spread the product E on a white alumina porcelain boat, spread a layer of conductive graphite evenly on it, and place it in a tube furnace with an argon atmosphere from room temperature to 1000 °C at a heating rate of 10 °C / min. ℃ to obtain product F, wherein the argon flow rate is 60 sccm;

[0045...

Embodiment 3

[0050] 1) Take 8g of dandelion and wash with distilled water and dry to obtain product A;

[0051] 2) Add 100mL of water to product A, then add 60mL of concentrated sulfuric acid, concentrated hydrochloric acid and concentrated nitric acid at a volume ratio of 6:2:2, stir with a glass rod for 10 minutes to fully react, and obtain solution B;

[0052] 3) Dilute solution B to pH=7, filter and dry to obtain product C;

[0053] 4) Add 5 mL of concentrated sulfuric acid and 45 mL of water to product C, place it in a hydrothermal reaction kettle at 180°C, and react for 24 hours to obtain solution D;

[0054] 5) Dilute solution D to pH=7, filter, and dry to obtain product E;

[0055] 6) Spread the product E on a white alumina porcelain boat, and spread a layer of conductive graphite evenly on it, and place it in a tube furnace with an argon atmosphere from room temperature to 1000 °C at a heating rate of 8 °C / min. ° C, reacted at 1000 ° C for 2 hours to obtain product F, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com