Preparation method of source core of germanium-68 radioactive source

A germanium chloride and germanium nitrate technology, which is applied in the field of preparation of germanium-68 radioactive source cores, can solve the problems of poor radiation resistance of ion exchange resin, distortion of PET image development, safety of operators, etc. Simple and easy to control, short reaction time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

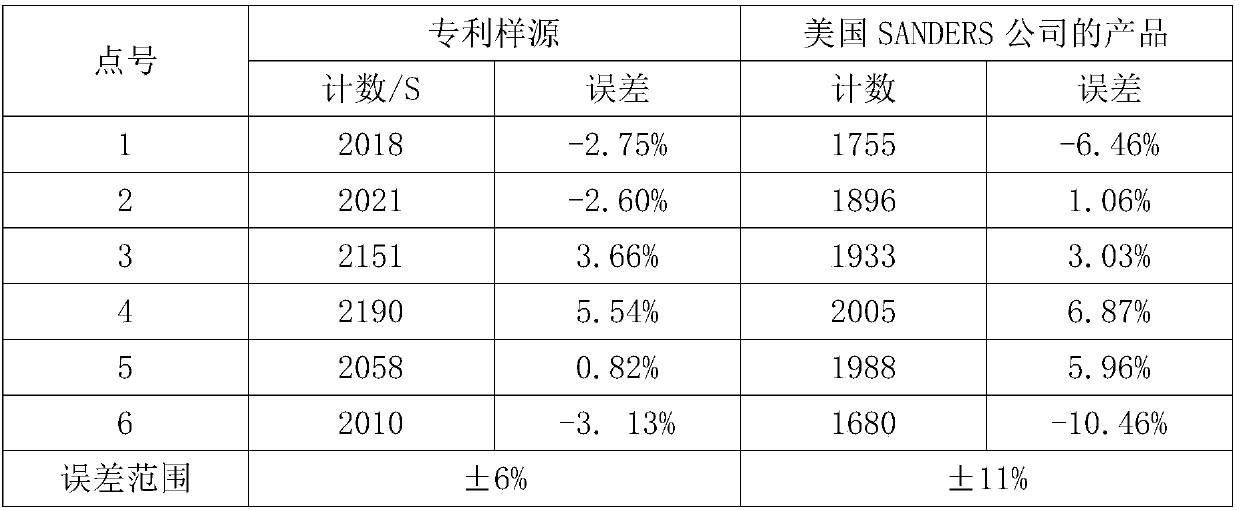

Image

Examples

Embodiment 1

[0021] A method for preparing germanium-68 radioactive source core, comprising the steps of:

[0022] In the reaction vessel, put 1 g of treated zirconium silicate particles with a particle size of 20 μm, add 5 mL of 2M hydrochloric acid aqueous solution, 1.5 mL of 0.5 M germanium chloride aqueous solution and 3 mL of 0.5 mCi / mL germanium chloride-68 aqueous solution and mix evenly. Shake and react for 40 minutes, discard the supernatant, wash twice with deionized water, then once with absolute ethanol, and dry at room temperature to obtain the source core of the germanium-68 radioactive source.

[0023] The zirconium silicate particles are treated by immersing the zirconium silicate particles in 1M hydrochloric acid aqueous solution for 20 minutes, washing with deionized water until neutral, and drying in an oven at 200°C.

[0024] Utilization rate of radioactive germanium-68=(1-activity of radioactive germanium-68 in the supernatant / activity of input radioactive germanium-68...

Embodiment 2

[0027] A method for preparing germanium-68 radioactive source core, comprising the steps of:

[0028] In the reaction vessel, put 1.5g of treated zirconium silicate particles with a particle size of 10μm, add 10mL 0.5M hydrochloric acid aqueous solution, 0.5mL 0.05M germanium chloride aqueous solution and 0.1mL 10mCi / mL germanium chloride-68 aqueous solution and mix Evenly, shake and react for 10 minutes, discard the supernatant, wash twice with deionized water, then wash once with absolute ethanol, and dry at room temperature to obtain the source core of the germanium-68 radioactive source.

[0029] The zirconium silicate particles are treated by soaking the zirconium silicate particles in 1.5M hydrochloric acid aqueous solution for 5 minutes, washing with deionized water until neutral, and drying in an oven at 250°C.

[0030] The activity of the radioactive germanium-68 in the supernatant was 0.025mCi, the activity of the input radioactive germanium-68 was 1.0mCi, and the ut...

Embodiment 3

[0032] A method for preparing germanium-68 radioactive source core, comprising the steps of:

[0033] In the reaction vessel, put 5g of treated zirconium silicate particles with a particle size of 80 μm, add 20mL of 1.5M hydrochloric acid aqueous solution, 2mL of 1.5M germanium chloride aqueous solution and 3.0mL of 5mCi / mL germanium chloride-68 aqueous solution and mix evenly. Shake and react for 30 minutes, discard the supernatant, wash twice with deionized water, then once with absolute ethanol, and dry at room temperature to obtain the germanium-68 radioactive core.

[0034] The zirconium silicate particles are treated by soaking the zirconium silicate particles in 2M hydrochloric acid aqueous solution for 15 minutes, washing with deionized water until neutral, and drying in an oven at 300°C.

[0035] The activity of radioactive germanium-68 in the supernatant was 0.113mCi, the activity of input radioactive germanium-68 was 7.5mCi, and the utilization rate of radioactive g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com