A LED chip structure based on flip-chip packaging

A LED chip and flip-chip packaging technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of large thermal resistance, reduced luminous efficiency, and unfavorable chip heat transmission, so as to improve performance and service life, reduce Small shading absorption, increasing the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

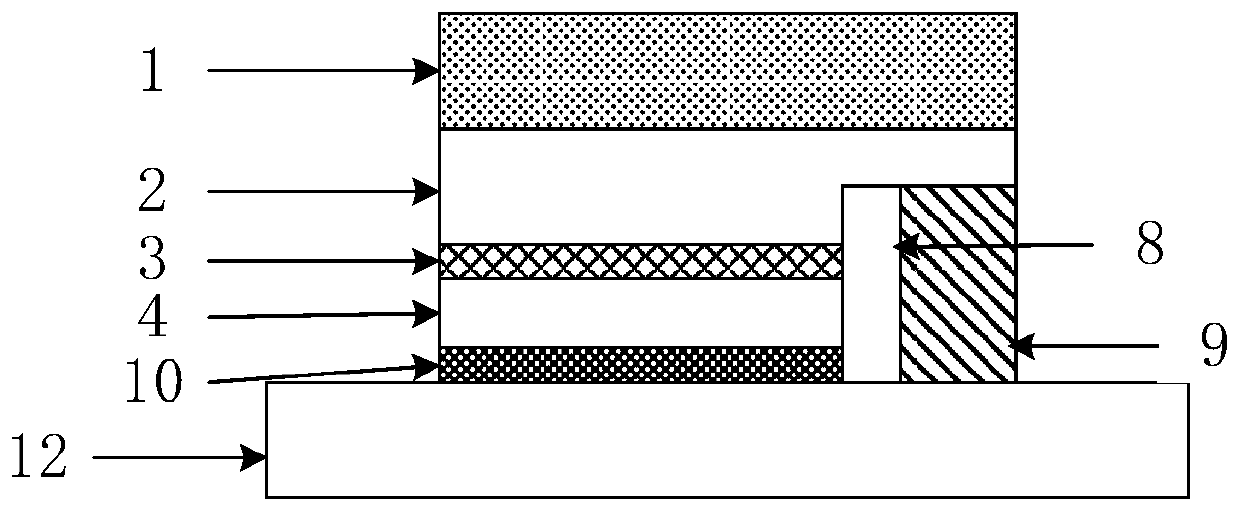

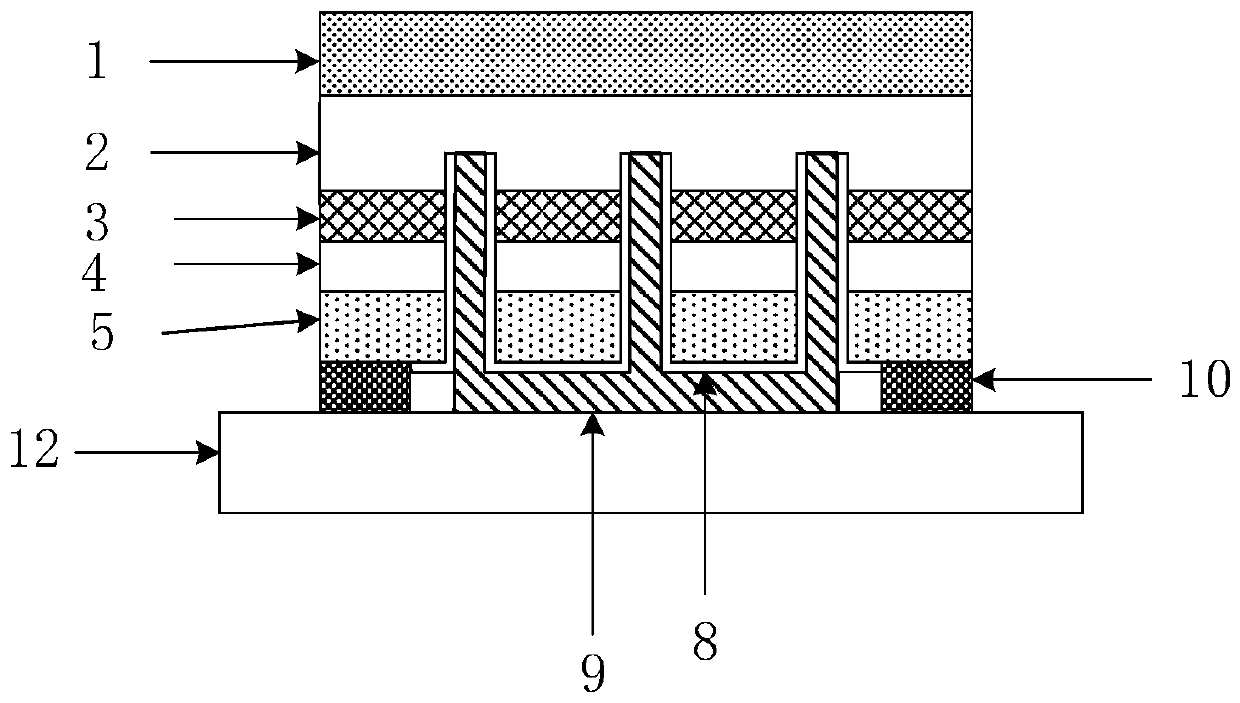

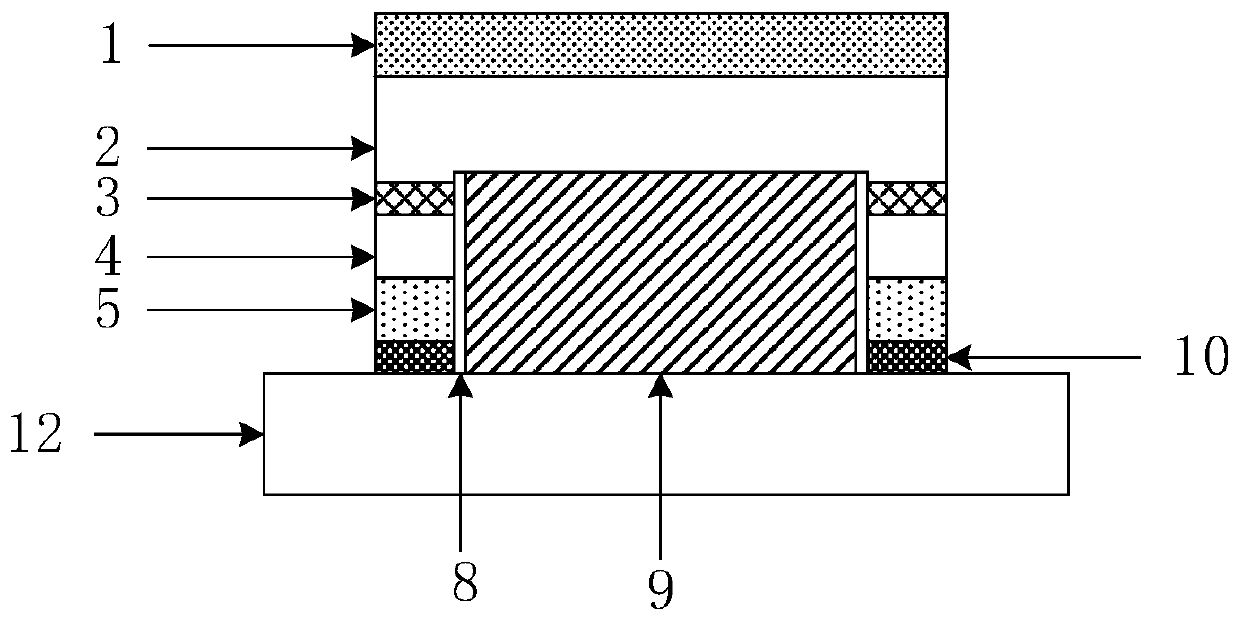

[0031] A LED chip structure based on flip-chip packaging, such as Figure 10 As shown, it includes a plurality of microcrystalline units, and the adjacent microcrystalline units are electrically isolated by a heat conduction channel 11 filled with high thermal conductivity insulating ceramics. Each microcrystalline unit includes a sapphire substrate 1, and the sapphire substrate N-type nitride layer 2, light-emitting layer (MQW) 3, P-type nitride layer 4, reflective layer 5, P-type electrode 10, N-type electrode 9 and passivation layer 8 grown sequentially on 1, each microcrystal The grain units are connected in series or / and in parallel through metal wires on the substrate 12; the N-type electrode 9 consists of a thin rectangular parallelepiped structure located on the substrate 12 and penetrates the reflective layer 5, the P-type nitride layer 4 and the light emitting The layer 3 is connected to the N-type nitride layer 2. It is composed of a broken-line strip structure. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com