Preparation method of thin film single thermal battery with central hole

A center hole and thin-film technology, which is applied in the manufacture of primary battery equipment, primary batteries, circuits, etc., can solve the problems of electrode material waste, short circuit, electrolyte diaphragm layer thickness, etc., to avoid battery failure, reduce manufacturing costs, simplify The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

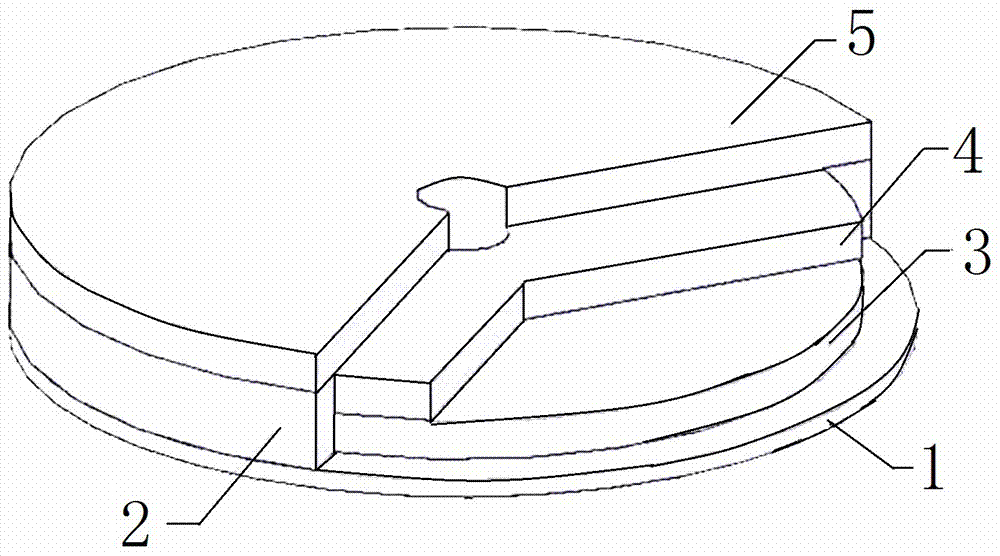

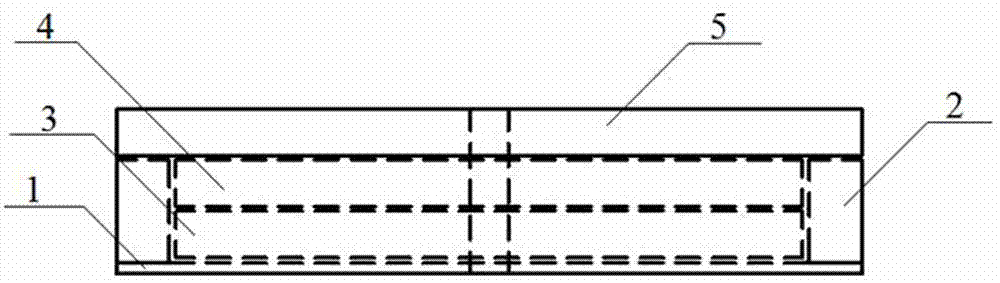

[0028] Such as figure 1 As shown, a method for preparing a thin-film monolithic thermal battery with a central hole includes a mold body. First, a collector sheet 1 with a central hole and an inert choke ring 2 are sequentially placed in the mold body from bottom to top. The negative electrode film and the electrolyte diaphragm are placed in the choke ring 2 sequentially, and finally the positive electrode film is placed on the upper end of the inert choke ring and moved to a hydraulic press for compression molding. (Placement order needs to be modified)

[0029] The current collector sheet 1, the negative electrode film sheet 3, the electrolyte diaphragm sheet 4 and the positive electrode film sheet 5 are all mesoporous sheet structures.

[0030] The material of the current collector sheet 1 is nickel sheet, stainless steel sheet, copper foil or graphite paper and the like.

[0031] The inert choke ring 2 is made of asbestos fiber and magnesium oxide, or is made by punching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com