Preparation method of polymer electrolyte membrane based on silicon-based negative electrode material

A silicon-based negative electrode material and electrolyte membrane technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of electrode material pulverization and shedding capacity, aggravating silicon corrosion and capacity decay, and restricting the application of silicon-based materials. The effect of reducing irreversible capacity, reducing direct contact and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0030] Embodiment 1~5 and comparative experiment

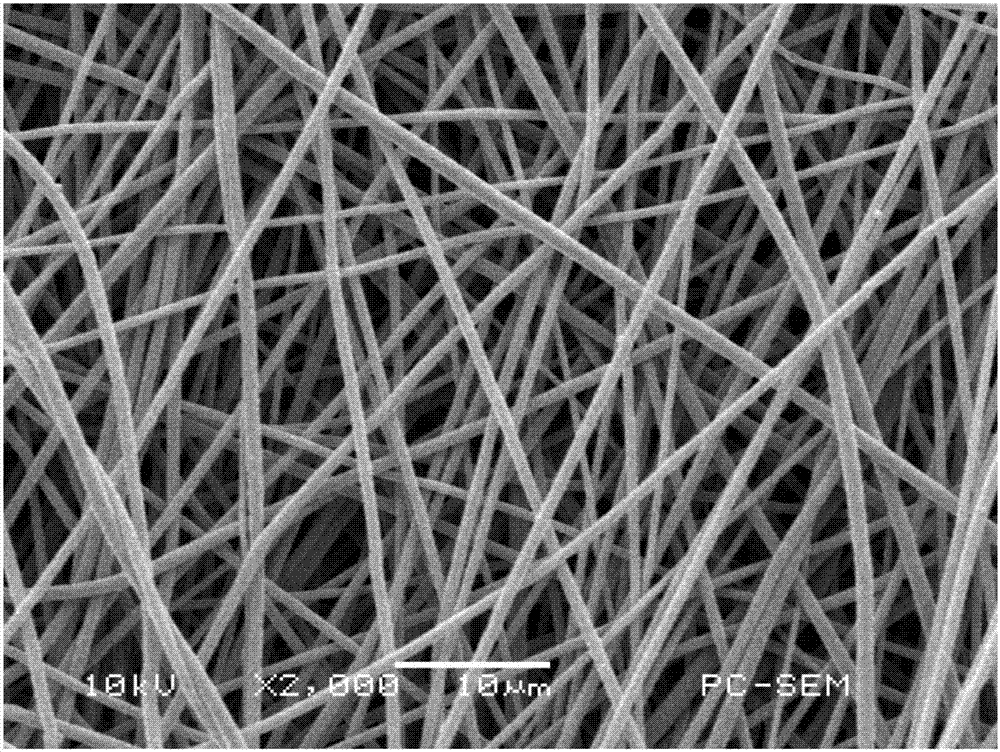

[0031] 1. According to the composition ratio of the spinning dope in Table 1, take by weighing PPC and polymers with polar groups (at least one of PMMA, PAN, TPU and PVdF), and add N,N-dimethylethyl ether Amide and acetone were magnetically stirred in a water bath at a constant temperature of 50° C. for 24 hours to obtain a spinning solution with a concentration of 12%. The obtained translucent solution was injected into a syringe, and spinning was performed at an injection volume of 0.5 ml / h according to the voltage in Table 1. The nanofiber composite polymer film was obtained after electrospinning for 10 h under constant temperature and humidity environment, and dried in a vacuum oven at 60° C. for 24 h. The composite gel polymer electrolyte is obtained after being activated by the electrolyte.

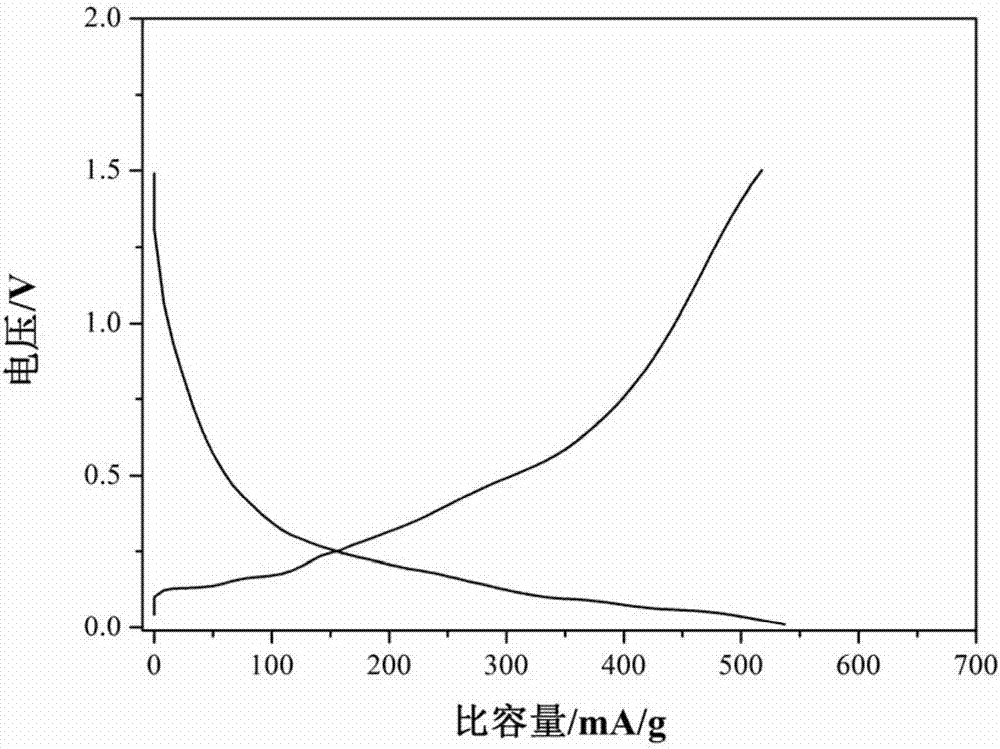

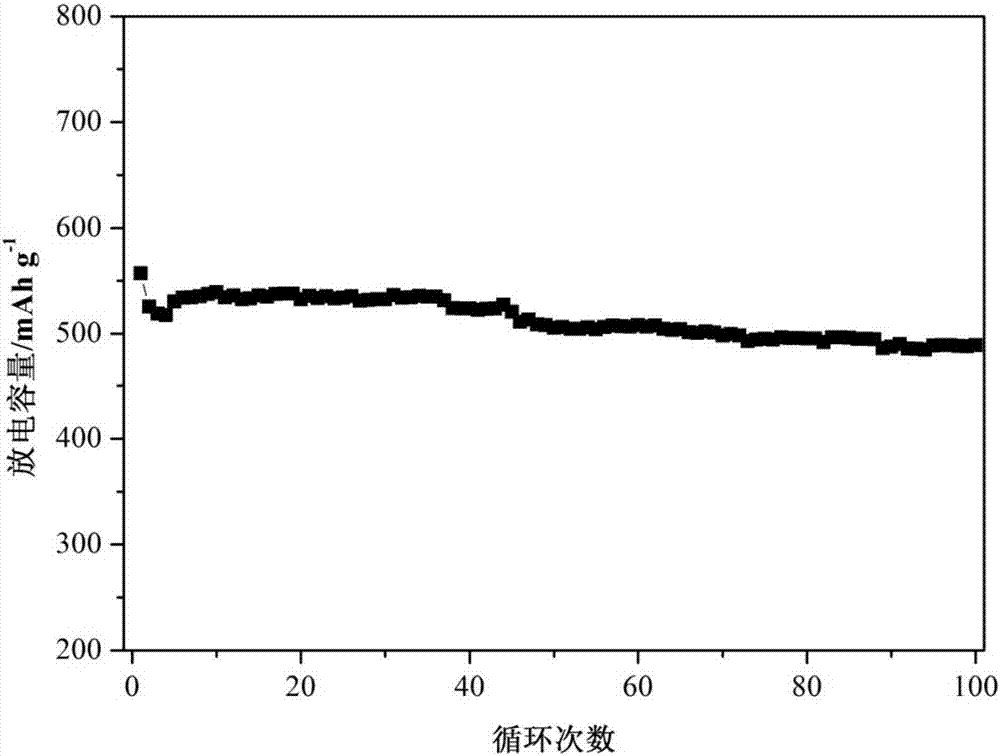

[0032] The ionic conductivity of composite polymer electrolytes was studied using AC impedance method. Mix the silicon carbon n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com