A formaldehyde purification device that uses flocculation yeast to absorb and degrade formaldehyde

A formaldehyde purification and flocculation technology, which is applied to gasification substances, chemical instruments and methods, separation methods, etc., can solve the problems of air purifier purification effect activated carbon purification effect is good, air purifier quality is uneven, and it is not suitable for air purification. Achieve the effect of improving efficiency, increasing contact area, and thorough process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

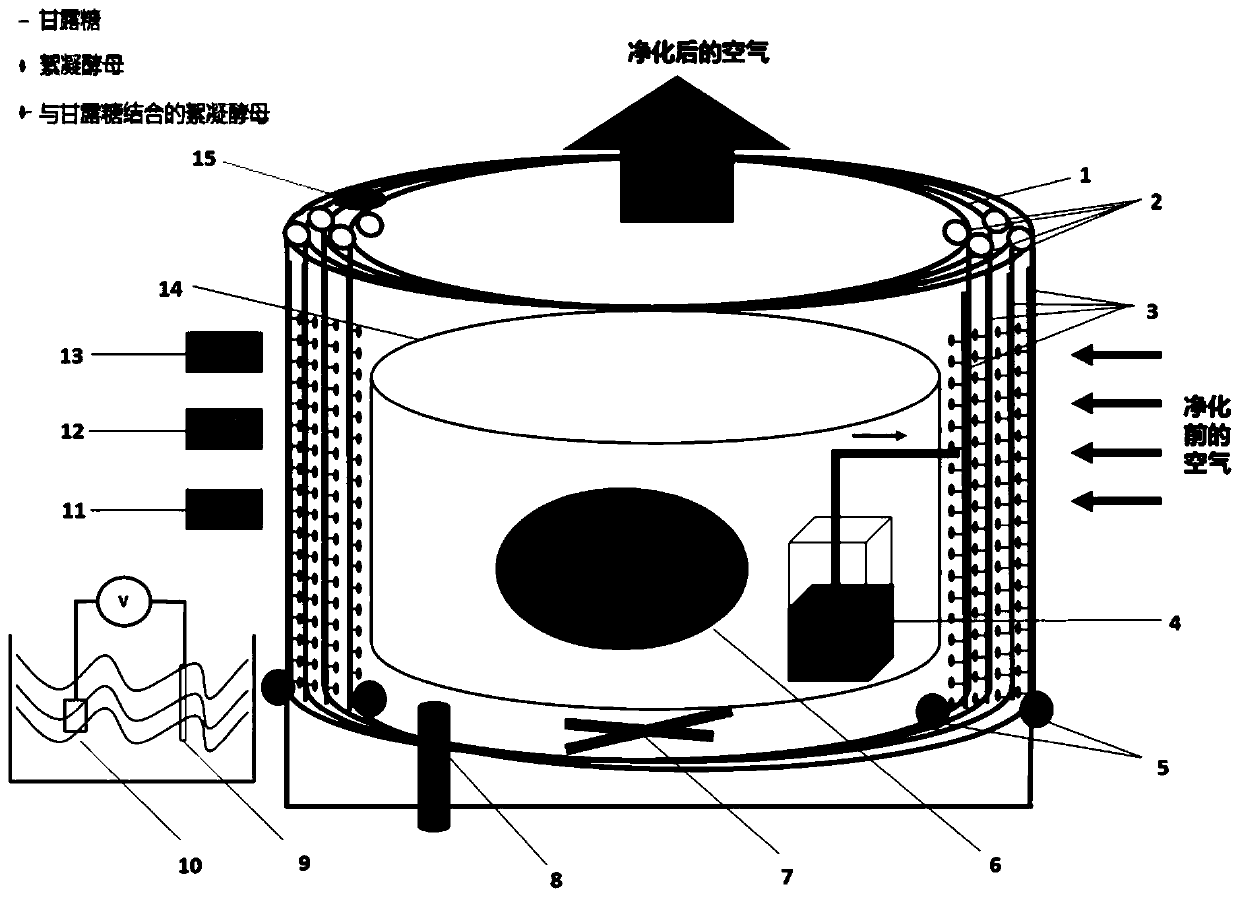

[0035] figure 1 A specific embodiment of the invention is shown. In this embodiment, the formaldehyde purification device using flocculation yeast to absorb and degrade formaldehyde includes a clean room, a real-time quantitative monitoring system for formaldehyde content, a spray system, a temperature control system, a pH control system, an ORP monitoring system and an air circulation system.

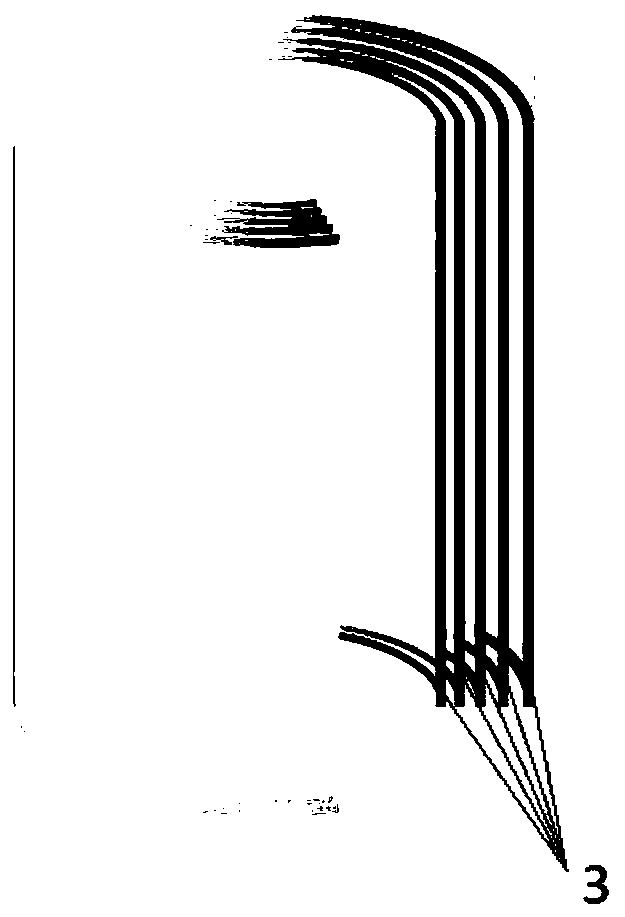

[0036] The clean room includes a culture room 1 and an inner room 14 . The inner chamber 14 is wrapped in the cultivation chamber 1 . The culture chamber 1 is a multi-layer sandwich structure, that is, a plurality of interlayer spaces are separated by multi-layer porous films 3, here are 4 layers, but not limited to 4 layers. figure 2 The multi-layer sandwich structure is shown, in which 5 layers of porous films 3 form a 4-layer sandwich space. The function of the porous film 3 is to fix mannose. After the flocculated yeast is cross-linked with the mannose on the porous film 3 , i...

Embodiment 2

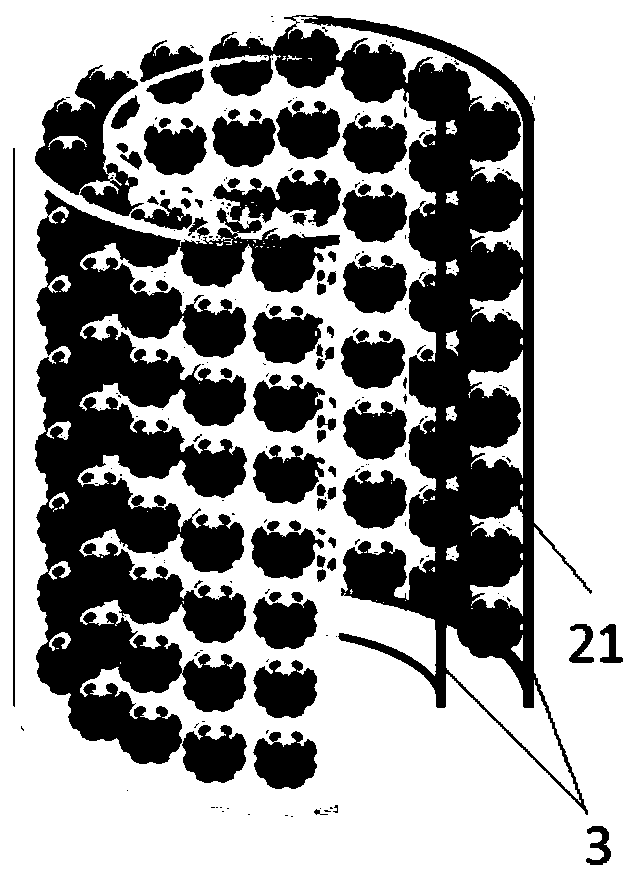

[0050] This embodiment is basically the same as Embodiment 1, except that the culture chamber is a packing structure. That is, the fixing method of the flocculated yeast is to utilize the porous filler 21 (such as Figure 4 shown) was filled in culture chamber 1. After the flocculated yeast cells are activated, the flocculated proteins are cross-linked and fixed with the mannose on the surface of the porous filler 21. The multi-attachment sites provided by the porous filler 21 for the flocculated yeast cells increase the contact area between the indoor formaldehyde and the flocculated yeast cells.

Embodiment 3

[0052] This embodiment is basically the same as that of Embodiment 1, except that the culture chamber is a structure combining packing and multiple interlayers. That is, the fixing method of the flocculated yeast is to utilize the porous filler 21 (such as Figure 4 shown) is filled in the interlayer structure formed by the porous film 3 (the number of interlayers is determined according to needs, generally 1-10 layers, image 3 Only one layer of structure is shown). After the flocculated yeast cells are activated, the flocculated protein is cross-linked and fixed with mannose on the surface of the porous filler 21. On the basis of the sandwich structure (especially the multi-layer sandwich structure) formed by the porous film 3, the porous filler 21 is the flocculated yeast cell. The multiple attachment sites provided further increase the contact area between indoor formaldehyde and flocculated yeast cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com