Preparation method of compound seaweed fertilizer

A fertilizer and seaweed technology, which is applied in the field of compound seaweed fertilizer preparation, can solve the problems of affecting the fertilizer effect and destroying the effective active ingredients of seaweed, and achieve the effect of reducing residue discharge, improving potency and lasting fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

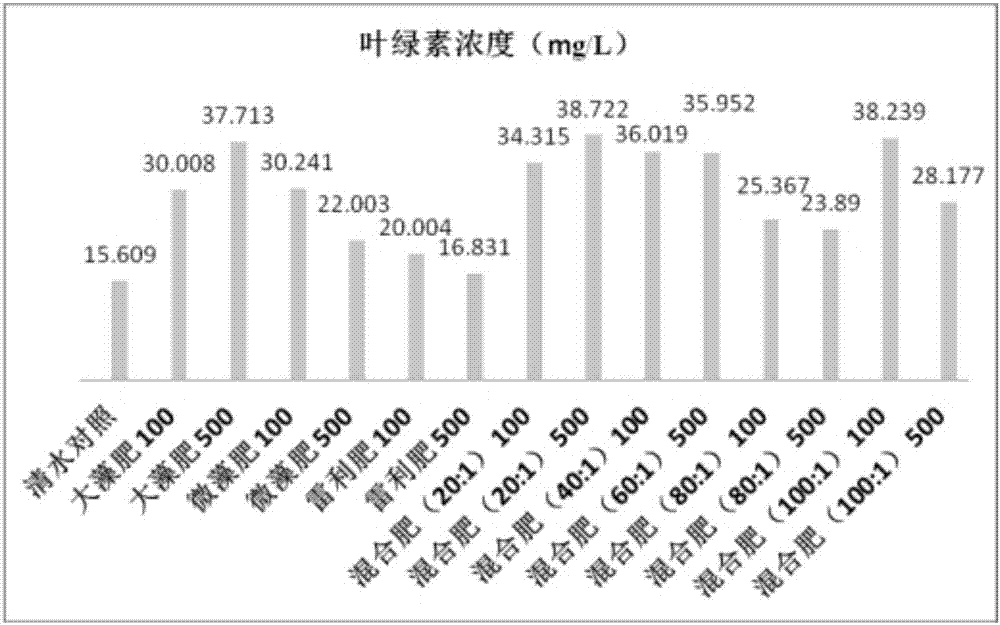

Image

Examples

Embodiment 1

[0032] In the present embodiment, the preparation method of compound seaweed fertilizer specifically comprises the following steps:

[0033] (1) Pretreatment: Fresh brown algae, red algae, green algae, sargassum, fucus, the mass ratio of brown algae, red algae, green algae, sargassum, and fucus is as follows: 70:10:10:5: 5. Wash repeatedly, filter out impurities, dehydrate until the water content is 45wt%, and freeze at -20°C for 6 hours; take it out and crush it with a tissue crusher until the particle size is 70 mesh, add water according to the mass ratio of material to liquid 1:0.8, and stir make a homogenate;

[0034] (2) Enzymolysis treatment: add β-1,4-glucanase, cellobiohydrolase, 1,4-β-mannuronate lyase, bromelain, glucoamylase to the obtained homogenate, ℃, pH 5, enzymatic hydrolysis for 10 hours, separate the enzymatic hydrolyzate and residue;

[0035] Among them, the amount of enzyme added is: β-1,4 glucanase 1.5g / L; cellobiohydrolase 2.2g / L; 1,4-β-mannuronate ly...

Embodiment 2

[0040] In the present embodiment, the preparation method of compound seaweed fertilizer specifically comprises the following steps:

[0041] (1) Pretreatment: Fresh brown algae, red algae, green algae, sargassum, fucus, the mass ratio of brown algae, red algae, green algae, sargassum, and fucus is as follows: 50:15:15:10: 10. Wash repeatedly, filter out impurities, dehydrate until the water content is 41wt%, and freeze at -16°C for 5 hours; take it out and crush it with a tissue crusher until the particle size is 60 mesh, add water according to the mass ratio of material to liquid 1:0.6, and stir make a homogenate;

[0042] (2) Enzymolysis treatment: add β-1,4 glucanase, cellobiohydrolase, 1,4-β-mannuronate lyase, bromelain, glucoamylase to the obtained homogenate, ℃, pH 4, enzymatic hydrolysis for 8 hours, and separate the enzymatic hydrolyzate and residue;

[0043] Among them, the amount of enzyme added is: β-1,4 glucanase 1.2g / L; cellobiohydrolase 2.1g / L; 1,4-β-mannuronate...

Embodiment 3

[0048] In the present embodiment, the preparation method of compound seaweed fertilizer specifically comprises the following steps:

[0049] (1) Pretreatment: Fresh brown algae, red algae, green algae, sargassum, fucus, the mass ratio of brown algae, red algae, green algae, sargassum, and fucus is as follows: 65:10:11:6: 8. Wash repeatedly, filter out impurities, dehydrate until the water content is 48wt%, and freeze at -22°C for 7 hours; take it out and crush it with a tissue crusher until the particle size is 80 mesh, add water according to the mass ratio of material to liquid 1:0.9, and stir make a homogenate;

[0050] (2) Enzymolysis treatment: add β-1,4-glucanase, cellobiohydrolase, 1,4-β-mannuronate lyase, bromelain, glucoamylase to the obtained homogenate, ℃, pH 6, enzymatic hydrolysis for 10 hours, separate the enzymatic hydrolyzate and residue;

[0051] Among them, the amount of enzyme added is: β-1,4 glucanase 2.4g / L; cellobiohydrolase 2.4g / L; 1,4-β-mannuronate ly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com