Process for preparing biological organic special composite fertilizer

A production process and organic technology, applied in the direction of organic fertilizers, fertilizers made from biological waste, inorganic fertilizers, etc., can solve the problems of wasting manpower and material resources, unable to supply fertilizer efficiency for a long time, etc., to reduce fertilizer use, inhibit breeding and reproduction, reduce Effects of using pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below with reference to the examples and figures, but the embodiments of the present invention are not limited thereto.

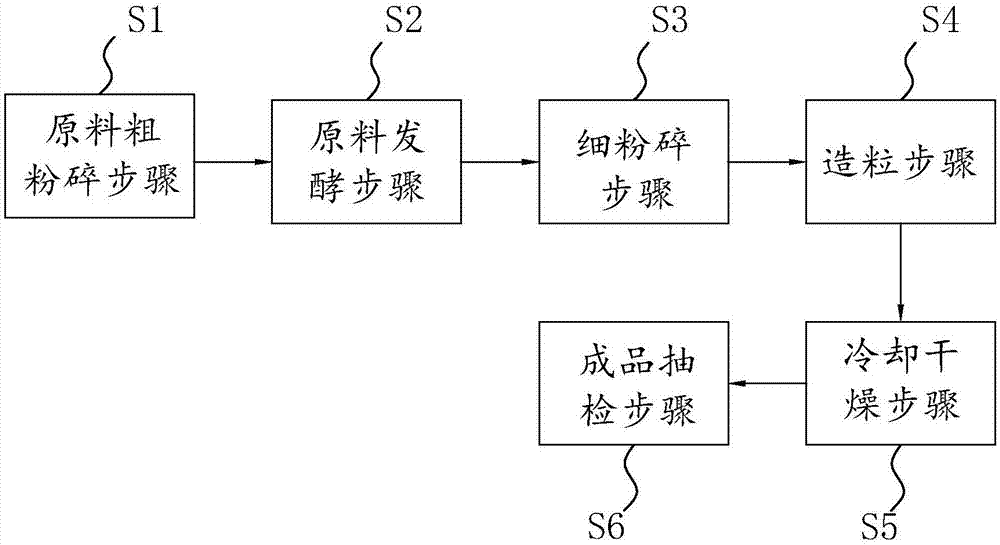

[0050] Such as figure 1 As shown, a kind of manufacturing process of bio-organic special compound fertilizer mainly goes through three processes of pulverization-mixing-granulation, and its specific process steps are as follows:

[0051] S1, raw material coarse crushing step, the straw ingredients are crushed, the length is controlled to 0.5-3.0CM, the livestock and poultry feces raw materials are crushed until they are not agglomerated, and impurities are screened out, wherein the weight ratio of livestock and poultry feces in the raw materials is 75-85 %, the ingredients are straw powder and / or waste fungus bud material, and the weight ratio is 15-25%;

[0052] S2, raw material fermentation step, adjust raw material moisture, add bacterial agent, deodorize fermentation, wherein, the moistur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com