Anti-radiation shielding masterbatches, as well as preparation method and application thereof

A radiation protection and masterbatch technology, applied in the field of textile fabrics, can solve problems such as pollution, electromagnetic radiation, and human injury, and achieve the effects of enhancing radiation protection, increasing effective concentration, and improving radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

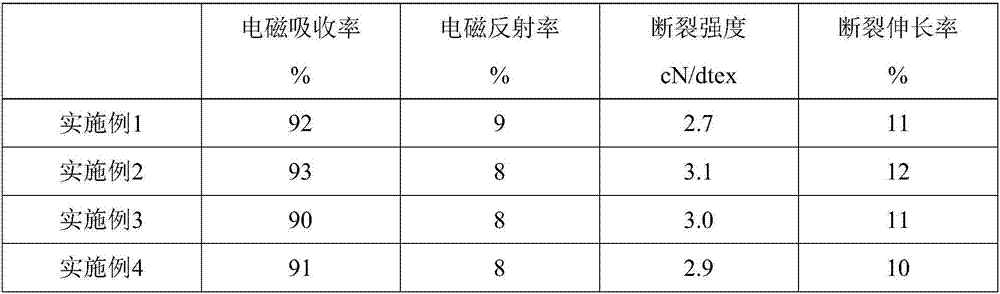

Examples

Embodiment 1

[0020] A kind of anti-radiation shielding masterbatch, raw materials include by weight: 20 parts of polyvinyl chloride, 5 parts of polypropylene, 3 parts of polycarbonate, 2 parts of compatibilizer, 1 part of coupling agent, 0.8 parts of emulsified silicone oil, dispersed 3 parts of agent, 2 parts of chitosan, 2 parts of boron carbide, 6 parts of micronized silica gel, 1.2 parts of glass fiber, and 0.5 part of plasticizer.

[0021] The compatibilizer is methyl methacrylate-butadiene-styrene terpolymer; the coupling agent is silane coupling agent KH-550; the dispersant is sodium metaphosphate; the plasticizer The agent is polyvinyl alcohol; the diameter of the glass fiber is 5 microns; the particle size of the micropowdered silica gel is 80 mesh.

[0022] The preparation method of above-mentioned radiation shielding masterbatch comprises the following steps:

[0023] Step 1, mixing polyvinyl chloride, polypropylene, polycarbonate, compatibilizer, coupling agent and emulsified ...

Embodiment 2

[0028] A kind of anti-radiation shielding masterbatch, raw materials include by weight: 23 parts of polyvinyl chloride, 7 parts of polypropylene, 5 parts of polycarbonate, 4 parts of compatibilizer, 2 parts of coupling agent, 1.1 parts of emulsified silicone oil, dispersed 5 parts of agent, 3 parts of chitosan, 4 parts of boron carbide, 7 parts of micronized silica gel, 1.8 parts of glass fiber, and 0.9 parts of plasticizer.

[0029] The compatibilizer is methyl methacrylate-butadiene-styrene terpolymer; the coupling agent is silane coupling agent KH-550; the dispersant is sodium metaphosphate; the plasticizer The agent is polyvinyl alcohol; the diameter of the glass fiber is 8 microns; the particle size of the micropowdered silica gel is 100 mesh.

[0030] The preparation method of above-mentioned radiation shielding masterbatch comprises the following steps:

[0031] Step 1, mixing polyvinyl chloride, polypropylene, polycarbonate, compatibilizer, coupling agent and emulsifi...

Embodiment 3

[0036] A kind of anti-radiation shielding masterbatch, raw materials include by weight: 27 parts of polyvinyl chloride, 8 parts of polypropylene, 5 parts of polycarbonate, 4 parts of compatibilizer, 3 parts of coupling agent, 1.3 parts of emulsified silicone oil, dispersed 5 parts of agent, 4 parts of chitosan, 4 parts of boron carbide, 8 parts of micronized silica gel, 1.9 parts of glass fiber, and 0.9 parts of plasticizer.

[0037] The compatibilizer is methyl methacrylate-butadiene-styrene terpolymer; the coupling agent is silane coupling agent KH-550; the dispersant is sodium metaphosphate; the plasticizer The agent is polyvinyl alcohol; the diameter of the glass fiber is 10 microns; the particle size of the micronized silica gel is 80 mesh.

[0038] The preparation method of above-mentioned radiation shielding masterbatch comprises the following steps:

[0039] Step 1, mixing polyvinyl chloride, polypropylene, polycarbonate, compatibilizer, coupling agent and emulsified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com