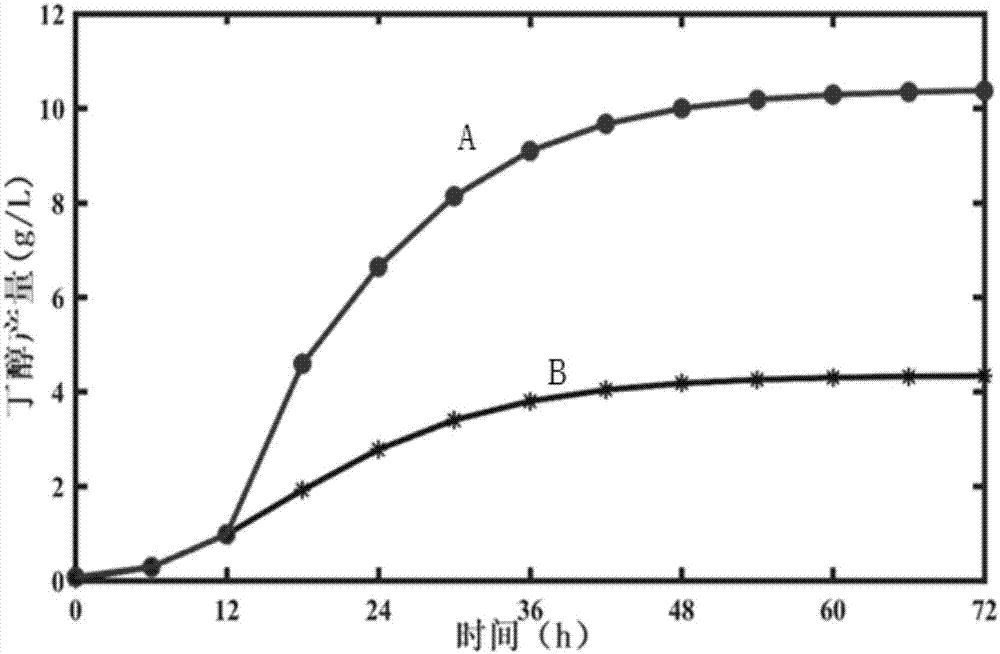

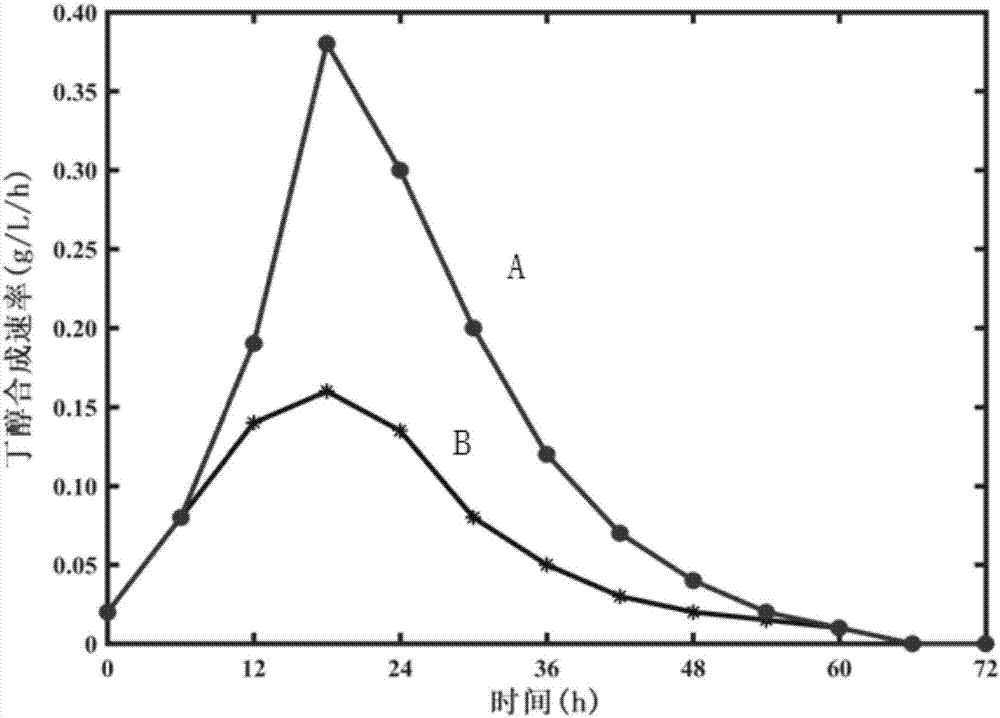

Method for improving activity of anaerobic bacteria for producing butanol

An anaerobic bacteria and butanol technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as yield reduction and acid collapse, reduce by-products, alleviate stress, and avoid rapid rise high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: a kind of method of improving anaerobic bacteria to produce butanol activity of the present embodiment, it is carried out according to the following steps:

[0022] 1. Inoculate the butanol-producing bacteria into the sterilized liquid anaerobic fermentation medium, and shake and cultivate it to the logarithmic phase under constant temperature conditions;

[0023] 2. After the bacterial growth reaches the logarithmic phase in step 1, add the butyric acid solution to the fermentation system of step 1, so that the concentration of the butyric acid solution in the fermentation system reaches 0.6 to 1.5 g / L;

[0024] 3. After adding the butyric acid solution, intermittently add the buffering agent to the fermentation system established in step 2, and continue to vibrate and cultivate under constant temperature conditions to obtain a butanol-based fermentation liquid, that is, to complete the described process of improving the fermentation system. Bu...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the liquid anaerobic fermentation medium described in step 1 contains a carbon source with a concentration of 40-60 g / L, 1-3 g / L yeast extract, 0.1~0.3g / L magnesium sulfate, 0.01~0.02g / L manganese sulfate, 0.01~0.02g / L ferrous sulfate, 0.01~0.02g / L sodium chloride, 0.001~0.002g / L vitamin B1, 0.3~0.7 g / L cysteine, 0.001-0.002g / L p-aminobenzoic acid, 0.0001g / L biotin and 0.1-0.2g / L resazurin. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the liquid anaerobic fermentation medium described in step one contains a carbon source with a concentration of 40-60 g / L, 2 g / L yeast extract, 0.2 g / L magnesium sulfate, 0.01g / L manganese sulfate, 0.01g / L ferrous sulfate, 0.01g / L sodium chloride, 0.001g / L vitamin B1, 0.5g / L cysteine, 0.001g / L p-amino Benzoic acid, 0.0001g / L biotin and 0.1g / L resazurin. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com