A wastewater treatment method for synchronous denitrification, phosphorus and ammonia nitrogen removal

A simultaneous nitrogen and phosphorus removal and wastewater treatment technology, applied in the direction of anaerobic digestion and treatment, can solve the problems of limited treatment efficiency, high treatment cost, single treatment object, etc., achieve strong phosphorus removal effect and increase the effect of utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A wastewater treatment method for synchronous denitrification, dephosphorization and ammonia nitrogen removal of the present invention, its implementation method is: (1) crush pyrrhotite until the particle size is 20-60 mesh, and expose the pyrrhotite by water washing or pickling The fresh surface is ready for use; (2) the magnesite with a particle size of 20-60 meshes is washed with water for use; (3) the pyrrhotite and magnesite are mixed and evenly added to the reaction vessel according to a certain mass ratio; (4) Add waste water containing ammonia nitrogen, nitrate nitrogen and phosphate into the reaction vessel; (5) Add a certain volume of sulfur autotrophic denitrifying bacteria culture solution into the reaction vessel; (6) Place the reaction vessel in anaerobic Or anoxic environment, after a few days of reaction, the wastewater treatment is completed.

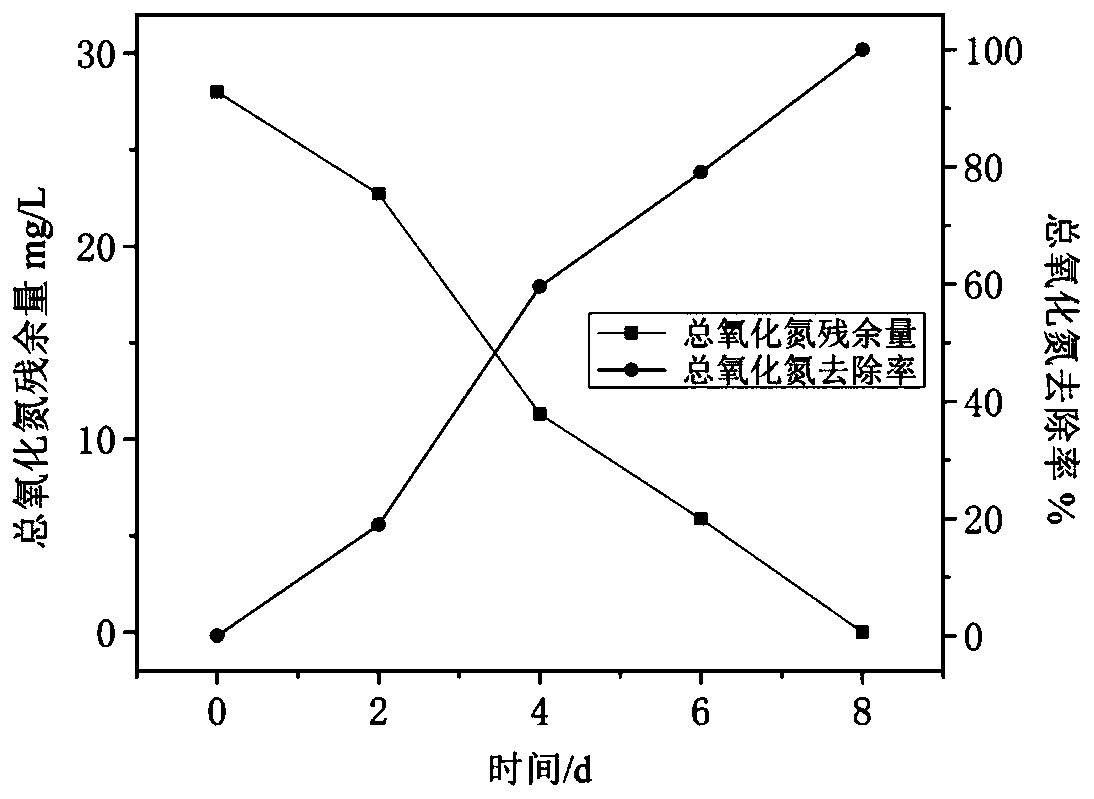

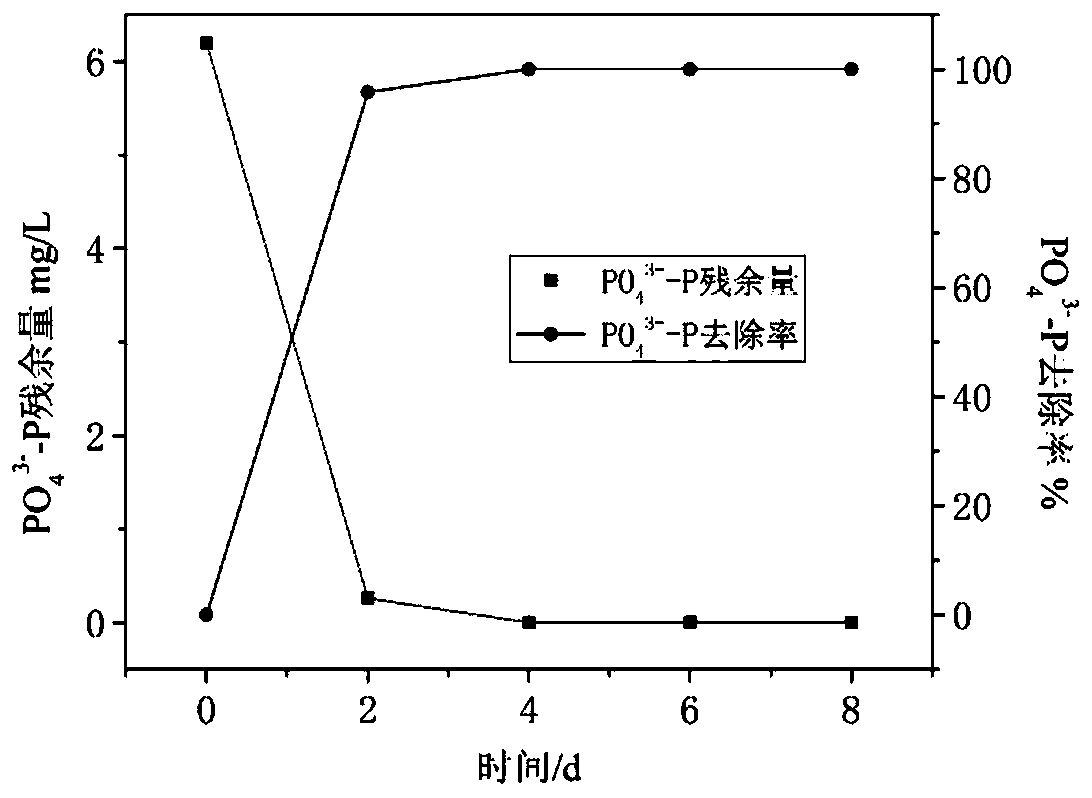

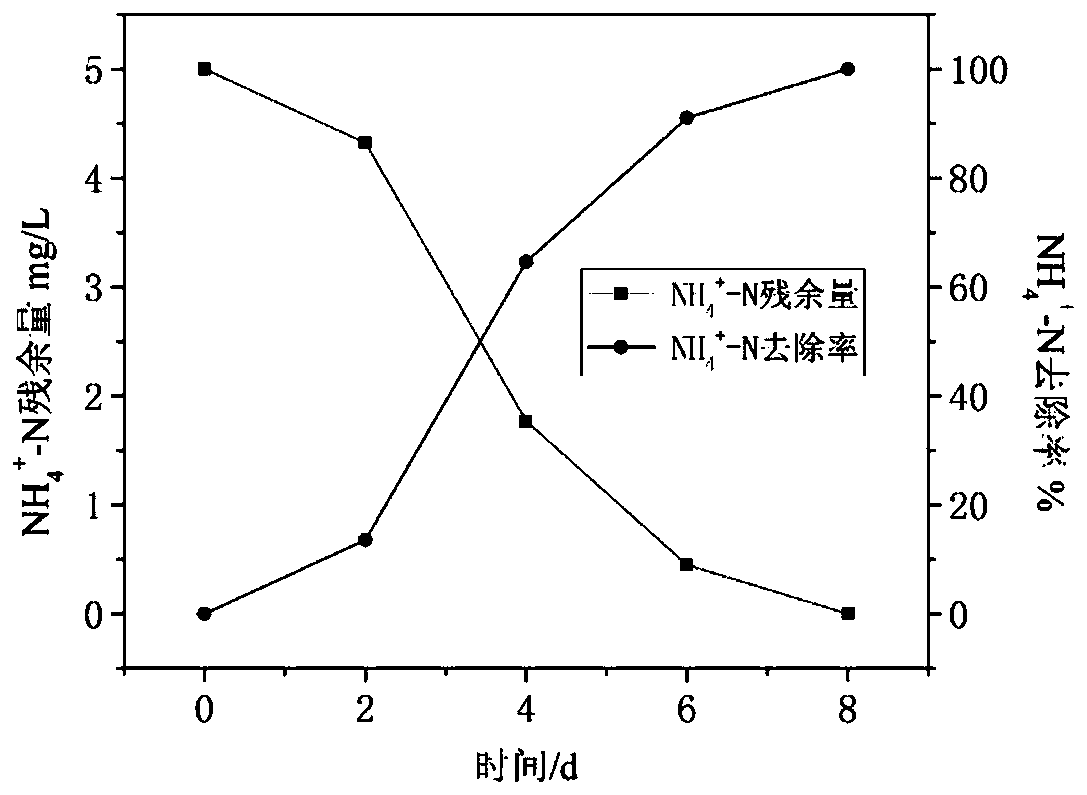

[0037] Such as Figure 1~3 Shown embodiment 1, present embodiment 1 gets pyrrhotite 9g, magnesite 3g and put...

Embodiment 2

[0040] The wastewater treatment steps of synchronous denitrification, dephosphorization, and ammonia nitrogen removal in Example 2 are basically the same as in Example 1, the only difference being: take 20 g of pyrrhotite and 7 g of magnesite into the reaction vessel, add NO 3 - -N 80mg / L, PO 4 3- -P 25mg / L, ammonia nitrogen 15mg / L wastewater 100mL, then add 4mL sulfur autotrophic denitrifying bacteria culture solution, blow nitrogen to deoxygenate, then cover and seal. The nitrate nitrogen was completely removed at 12 days, the phosphate phosphorus was completely removed at 6 days, and the ammonium nitrogen was completely removed at 11 days.

Embodiment 3

[0042] The waste water treatment steps of synchronous denitrification, dephosphorization and ammonia nitrogen removal of the present embodiment 3 are basically the same as those of the embodiment 1, the only difference being that the present embodiment 3 takes 7 g of pyrrhotite and 4 g of magnesite and puts them into the reaction vessel. Add NO 3 - -N 36mg / L, PO 4 3- - 40mL of waste water with P13mg / L and ammonia nitrogen 9mg / L, then add 3.4mL sulfur autotrophic denitrifying bacteria culture solution, blow nitrogen to remove oxygen, and then cover and seal. The nitrate nitrogen was completely removed at 7 days, the phosphate phosphorus was completely removed at 5 days, and the ammonia nitrogen was completely removed at 10 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com