Modified polyisocyanate composition and preparation method thereof

A technology of polyisocyanate and isocyanurate, which is applied in the field of polyisocyanate, can solve the problems that leather cannot be applied, leather has no resilience, and performance is single, and achieve the effects of reducing personal injury, easy control of reaction, and high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

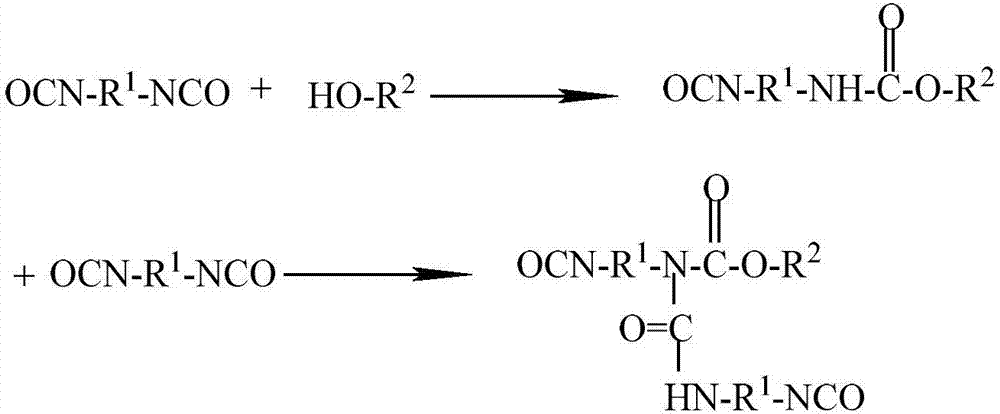

[0023] The invention provides a kind of preparation method of the modified polyisocyanate composition, comprises the following steps:

[0024] 1) reacting monohydric alcohol and polyisocyanate under heating conditions, heating while stirring, to obtain carbamate;

[0025] 2) Continue to add polyisocyanate, and carry out secondary reaction under the condition of catalyst and heating at 100°C-150°C to generate polyisocyanate composition.

[0026] Firstly, step 1) is carried out: react the monohydric alcohol and the polyisocyanate under heating conditions, and heat while stirring.

[0027] Polyisocyanate is one of the main raw materials of polyurethane resin. The polyisocyanate used in the manufacture of polyurethane resin includes diisocyanate, triisocyanate and their modified bodies. The polyisocyanate molecule contains two or more active sites, so when the polymerization reaction occurs, it can be extended to two ends or three directions to form a linear or cross-linked (body...

Embodiment 1

[0042] Weigh 62g (about 0.33mol) of analytically pure dodecanol in the reactor, weigh 75g (about 0.34mol) of isophorone diisocyanate (IPDI), slowly heat up to 80°C under stirring, and then keep at 80°C Reaction 2h. Add 0.5 g of zinc isooctanoate, weigh 296 g (about 1.33 mol) of IPDI, slowly add it into the reaction system, and finish adding in about 30 minutes. While adding IPDI, raise the temperature. After the addition, the temperature rises to 130° C. After the reaction is completed, the temperature is lowered immediately, and the polyisocyanate composition can be obtained by discharging at about 60°C.

[0043] The polyisocyanate composition contained 21.4% by weight of NCO groups, contained 52% by weight of IPDI monomer, 28% by weight of allophanate and 20% by weight of isocyanurate. polyisocyanate composition at 25°C and 200 sec -1 The viscosity at the shear rate is 675mPa / s.

Embodiment 2

[0045] Weigh 62g (about 0.33mol) of dodecanol and 58g (about 0.33mol) of toluene diisocyanate (TDI) in the reactor, slowly raise the temperature to 70°C under stirring, and then keep it at 70°C for 3h. Add 0.35g of dibutyltin dilaurate, raise the temperature to 120°C, weigh 348g (about 2.00mol) of TDI, slowly add it into the reaction system, add it in about 30 minutes, and keep it at 120°C for 4 hours after the addition. Immediately after the reaction, the temperature is lowered, and the polyisocyanate composition liquid can be obtained by discharging at about 80°C.

[0046] The polyisocyanate composition 100% liquid product contained 17.6% by weight of NCO groups, contained 58% by weight of TDI monomer, 26% by weight of allophanate and 16% by weight of isocyanurate. polyisocyanate composition at 25°C and 200 sec -1 The viscosity at the shear rate is 890mPa / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com