Preparation method of high-flavone selenium-enriched ampelopsis grossedentata granular beverage

A high-flavonoid and selenium-enriched technology, applied in the field of food processing, can solve the problems of backward processing technology, poor health care effect, loss of active ingredients, etc., and achieve the effects of long fragrance retention, reduced loss and transformation, and uniform quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

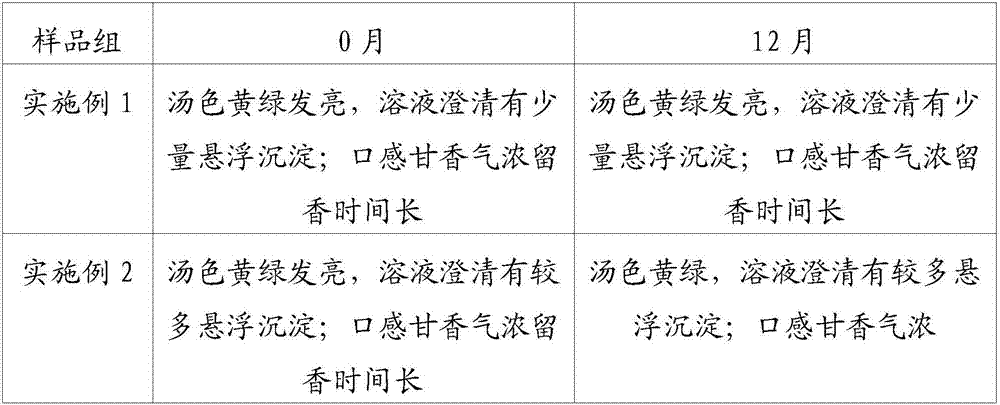

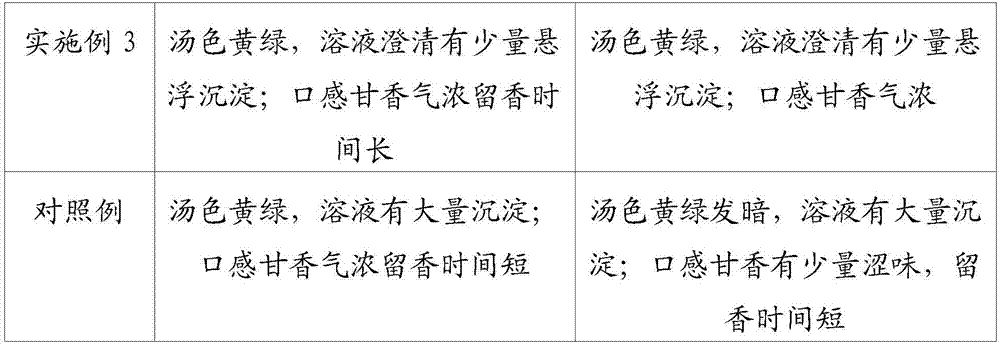

Examples

Embodiment 1

[0017] 1) Wash and mash the vine tea leaves, add 25 times of water and 0.025 times of cellulase according to the weight of the vine tea leaves, carry out microwave-assisted extraction at 60°C, microwave power 150W, extraction time 1h, then filter, and put the filtrate in Concentrate under reduced pressure below 50°C to a clear paste with a relative density of 1.2;

[0018] 2) Take another rattan tea leaf, wash it and grind it into a coarse powder, then mix it with the clear paste in step 1) in a weight ratio of 8:1, freeze-dry and grind it into a fine powder that can pass through a 300-mesh sieve;

[0019] The freeze-drying procedure is as follows: first place the mixed material in a freezer with a temperature of -30°C for rapid freezing; then place the material in a vacuum drying oven with a vacuum degree of 20 Pa, and increase the temperature of the material by 2 hours per hour. The temperature was raised to 30°C at a rate of °C, and kept at 30°C for 8 hours, and then remove...

Embodiment 2

[0023] 1) Wash and crush the rattan tea leaves, add 30 times of water and 0.02 times of cellulase according to the weight of the rattan tea leaves, carry out microwave-assisted extraction at 50°C, microwave power 200W, extraction time 0.5h, then filter, and the filtrate Concentrate under reduced pressure below 50°C to a clear paste with a relative density of 1.1;

[0024] 2) Take another rattan tea leaf, wash it and crush it into a coarse powder, then mix it with the clear paste in step 1) in a weight ratio of 3:1, freeze-dry and crush it into a fine powder that can pass through a 250-mesh sieve;

[0025] The freeze-drying procedure is as follows: first place the mixed material in a freezer with a temperature of -20°C for rapid freezing; then place the material in a vacuum drying oven with a vacuum degree of 10 Pa, and increase the temperature of the material by 1 hour per hour. The temperature was raised to 40°C at a rate of °C, and kept at 40°C for 5 hours, and then removed....

Embodiment 3

[0028] 1) Wash and mash the vine tea leaves, add 10 times water and 0.05 times cellulase according to the weight of the vine tea leaves, carry out microwave-assisted extraction at 70°C, microwave power 100W, extraction time 1h, then filter, and cool the filtrate Concentrated under reduced pressure to a clear paste with a relative density of 1.3;

[0029] 2) Another rattan tea leaf was taken, washed and crushed into a coarse powder, then mixed with the clear paste in step 1) in a weight ratio of 5:1, freeze-dried and crushed into a fine powder capable of passing through a 350-mesh sieve;

[0030] The freeze-drying procedure is as follows: first place the mixed material in a freezer with a temperature of -35°C for rapid freezing; then place the material in a vacuum drying oven with a vacuum degree of 15 Pa, and increase the temperature of the material by 1.5 degrees per hour. The temperature was raised to 25°C at a rate of °C, and kept at 25°C for 10 hours, and then removed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com