Preparation and application of purple onion pigment

An onion and pigment technology, applied in the preparation and application of purple onion pigment, can solve the problems of waste water, waste environmental pollution, expensive indicators, unfavorable large-scale use, etc., achieve a wide range of raw material sources, prevent anthocyanin degradation, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation steps of purple onion pigment:

[0022] 1) Remove the inedible parts of fresh onions, rinse them repeatedly with tap water and distilled water, dry them under natural conditions, take 20g of purple onions, cut them into small pieces, and beat them into a homogenate at 4°C;

[0023] 2) Take the homogenate and add 60 mL of methanol containing 0.1% hydrochloric acid, and sonicate 3 times at room temperature, 10 min each time;

[0024] 3) Buchner funnel vacuum filtration;

[0025] 4) The filter residue was extracted twice with 40 mL of methanol solution containing 0.1% hydrochloric acid, and the filtrates were combined for three times;

[0026] 5) Concentrate in vacuo at 40°C to remove methanol, and dilute to 25 mL with deionized water containing 0.01% hydrochloric acid to obtain a purple onion pigment solution. After calculation, the anthocyanin content in the crude extract obtained in this example is 19.36 mg / g.

Embodiment 2

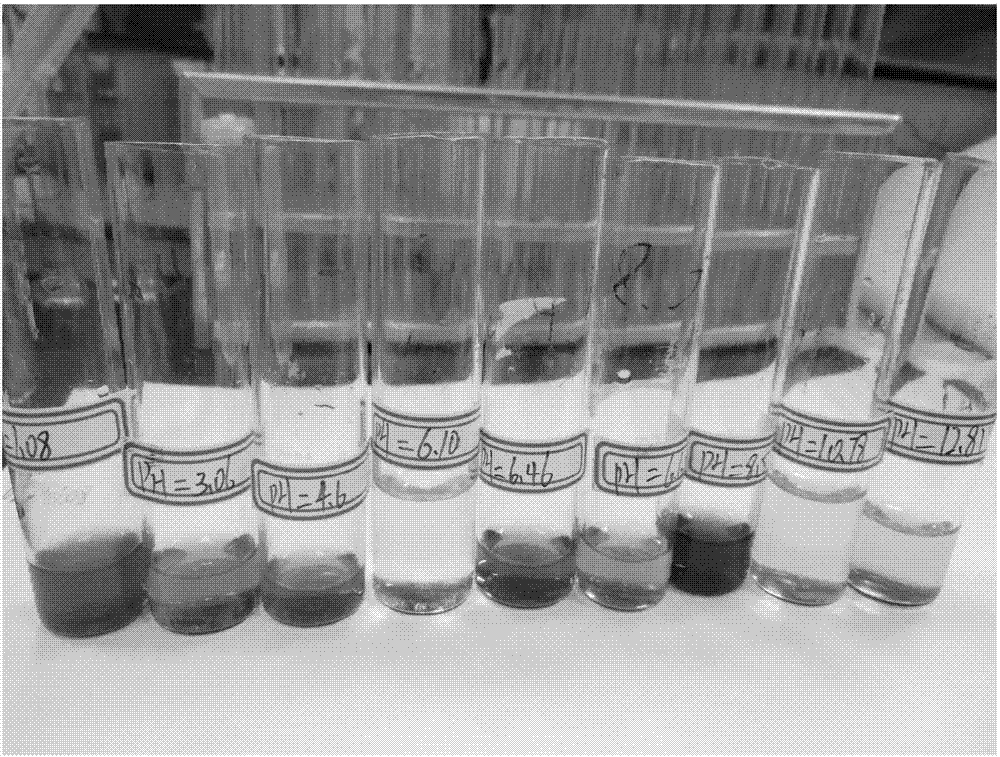

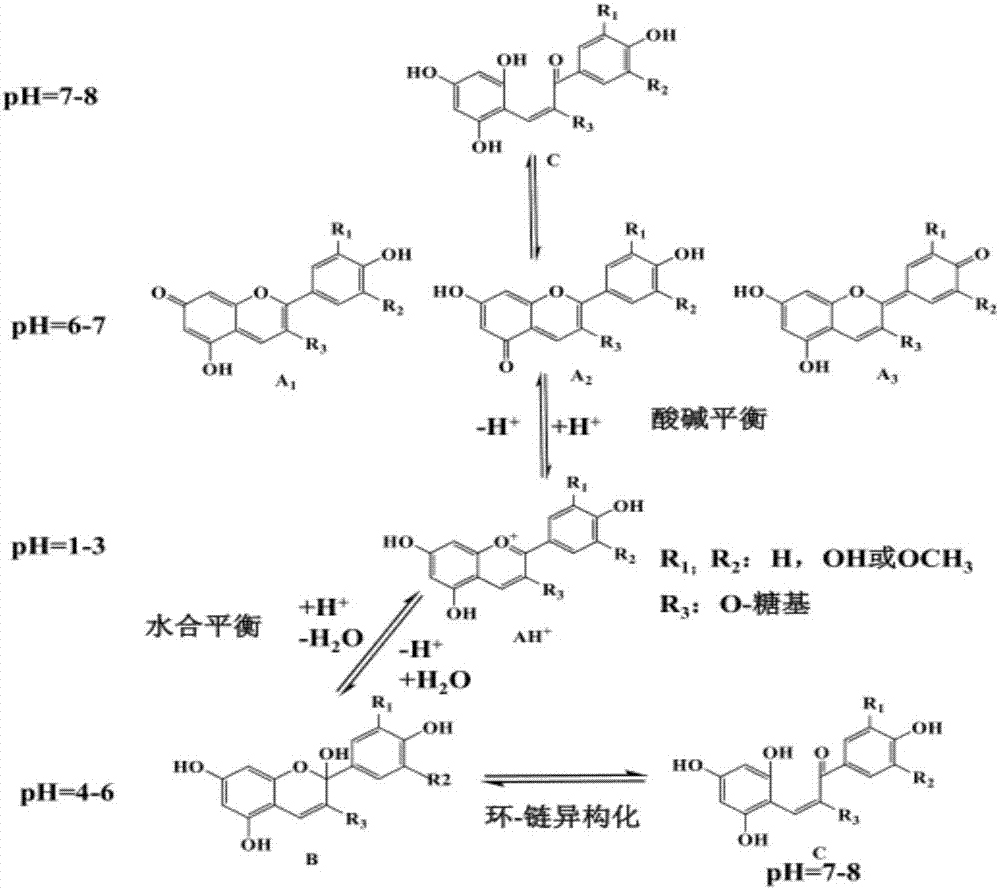

[0028] Get 1mL of the pigment solution of Example 1, use a pH meter to measure that the purple onion pigment is acidic, the pH is 1.87, and the color is bright red. Add 0.1mol / L NaH dropwise 2 PO 4 Solution, solution pH ≤ 3, showing bright red.

Embodiment 3

[0030] Take 1mL of the pigment solution of Example 1, add 1mol / L NaOH solution dropwise, use a pH meter to measure the pH value of the solution, and observe the color of the solution. The results are as follows: the pH of the solution is 3-5, showing purple and darker color ; Solution pH ≥ 6.5, it is green; solution pH ≥ 12, it is yellow. The color change is obvious and easy to judge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com