Preparation method of zirconium silicate-coated black pigment

A technology of zirconium silicate and black material, applied in fibrous fillers and other directions, can solve the problems of unsuitability for industrial production, large production energy consumption, long preparation period, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

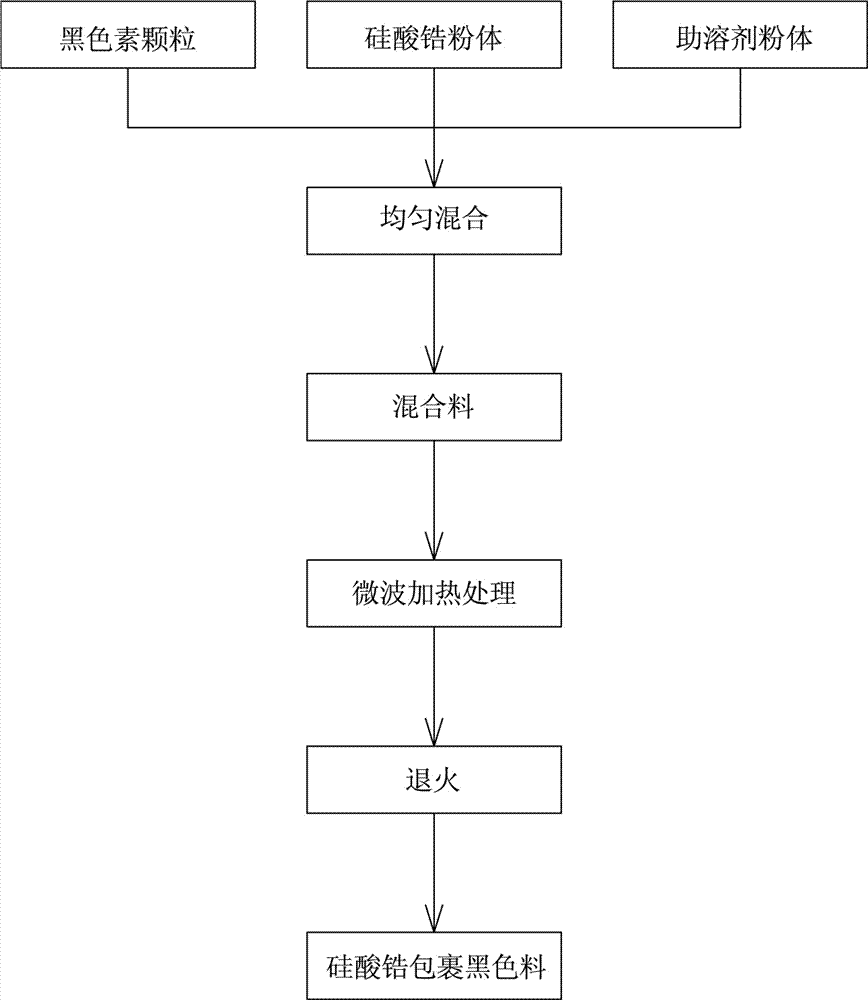

[0023] like figure 1 As shown, 20g of graphite powder, 1g of zirconium silicate powder, and 0.2g of lithium fluoride mineralizer were ground and mixed evenly to form a mixture. Then the mixture was placed in a microwave oven, treated with microwaves at a power of 500W for 10s, and then annealed to obtain a zirconium silicate-coated black material.

Embodiment 2

[0025] like figure 1 As shown, 20g of graphite powder, 5g of zirconium silicate powder, and 1g of lithium fluoride mineralizer were ground and mixed evenly to form a mixture. Then put the mixed material in a microwave oven, treat it with 80W microwave for 10min, and then anneal to prepare the zirconium silicate coated black material.

Embodiment 3

[0027] like figure 1 As shown, 20g of graphite powder, 10g of zirconium silicate powder, and 1.5g of lithium fluoride mineralizer were ground and mixed evenly to form a mixture. Then the mixture was placed in a microwave oven, treated with microwaves at 200W for 10 minutes, and then annealed to obtain a zirconium silicate-coated black material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com