Performance additive used in leather working

A technology of modification and auxiliary agent, applied in the field of modification auxiliary agent, can solve the problems that leather auxiliary agent cannot meet the needs of tanning, and the quality of tanning is greatly affected, so as to achieve surface compaction, compact leather structure, and improve the quality of leather. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

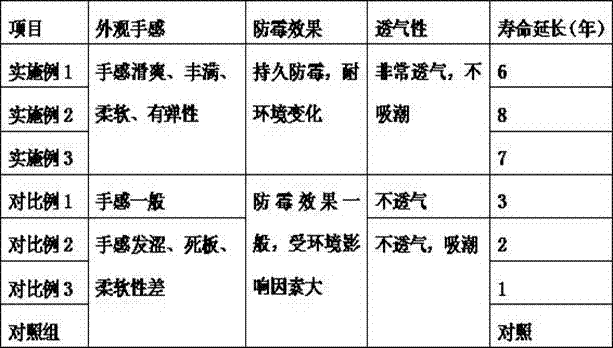

Examples

Embodiment 1

[0013] A modified auxiliary agent used in leather processing, adding rare earth compounds and vegetable syntans to the tanning agent, wherein the rare earth compound accounts for 1.0% of the tanning agent mass fraction, including lanthanum oxide, praseodymium oxide, holmium oxide, and europium oxide , the addition ratio is 4:2:1:0.3, and the mass fraction of vegetable syntans is 4.5%.

[0014] As a further description of the above scheme, the immersion aid used in the water immersion process is made of the following components in parts by weight: 15 parts of acetic acid, 10 parts of sodium sulfate, 5 parts of pulling powder BX, 12 parts of sodium petroleum sulfonate, Penetrant JFC 3 parts, penetrant M 2 parts, sodium methylene bis-naphthalene sulfonate 14 parts, OP-10 7 parts, AE0-9 20 parts.

[0015] As a further description of the above scheme, the preparation method of the vegetable syntan is as follows: take by weight 40 parts of black fern, 30 parts of sycamore, 25 parts ...

Embodiment 2

[0018] A modified auxiliary agent used in leather processing, adding rare earth compounds and vegetable syntans to the tanning agent, wherein the rare earth compound accounts for 1.3% of the tanning agent mass fraction, including lanthanum oxide, praseodymium oxide, holmium oxide, and europium oxide , the addition ratio is 5:2.5:1.5:0.4, and the mass fraction of vegetable syntans is 5.0%.

[0019] As a further description of the above scheme, the immersion aid used in the water immersion process is made of the following components in parts by weight: 16 parts of acetic acid, 11 parts of sodium sulfate, 6 parts of pulling powder BX, 13 parts of sodium petroleum sulfonate, Penetrant JFC 4 parts, penetrant M 3 parts, sodium methylene bis-naphthalene sulfonate 15 parts, OP-10 8 parts, AE0-9 22 parts.

[0020] As a further description of the above scheme, the preparation method of the vegetable syntan is as follows: take by weight 43 parts of black fern, 32 parts of phoenix tree, 3...

Embodiment 3

[0023] A modified auxiliary agent used in leather processing, adding rare earth compounds and vegetable syntans to the tanning agent, wherein the rare earth compound accounts for 1.5% of the tanning agent mass fraction, including lanthanum oxide, praseodymium oxide, holmium oxide, and europium oxide , the addition ratio is 6:3:2:0.5, and the mass fraction of vegetable syntans is 5.5%.

[0024] As a further description of the above scheme, the immersion aid used in the water immersion process is made of the following components in parts by weight: 18 parts of acetic acid, 12 parts of sodium sulfate, 8 parts of pulling powder BX, 14 parts of sodium petroleum sulfonate, Penetrant JFC 5 parts, penetrant M 4 parts, sodium methylene bis-naphthalene sulfonate 16 parts, OP-10 10 parts, AE0-9 25 parts.

[0025] As a further description of the above scheme, the preparation method of the vegetable syntan is as follows: take by weight 45 parts of black fern, 35 parts of phoenix tree, 35 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com