A method for determining niobium content in titanium-niobium alloy

A titanium-niobium alloy and content technology, applied in the field of chemical analysis, can solve the problems that the detection method cannot be applied, the niobium content cannot be detected, and the popularization and application of memory alloy materials are restricted, and the effect of clarification and stability of the sample solution is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

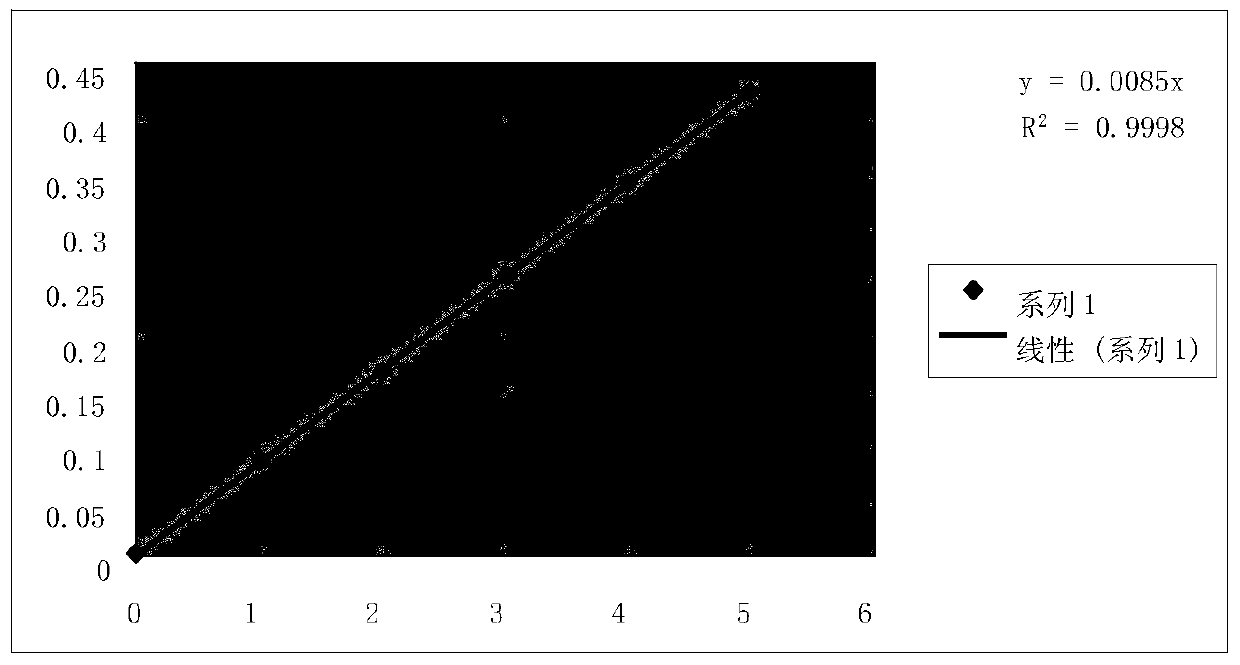

Embodiment 1

[0062] 3 sample test material

[0063] Weigh 0.0998g sample material, accurate to 0.0001g.

[0064] 4 Preparation of test solution

[0065] 4.1 Put the sample (3) in a 150 mL polytetrafluoroethylene beaker, add 5 mL of nitric acid (2.1), dropwise add 1 mL of hydrofluoric acid (2.3), heat at low temperature until the sample dissolves, cool slightly, add 20 mL of sulfuric acid (2.5), heat at low temperature until the volume of the solution is about 20mL, remove it, transfer it into a 250mL beaker, heat until sulfuric acid fumes are emitted, and heat until the first sulfuric acid fumes are emitted for about 3~4min, remove the beaker and cool slightly, and then pour into the beaker Blow in a small amount of water, heat until the second sulfuric acid fume is emitted for about 2~3 minutes, cool, add 20 mL tartaric acid solution (2.6), 5 mL ammonium fluoride solution (2.7), boil for 2~3 minutes, take it off, add 10 Continue to boil mL of saturated boric acid solution (2.8), cool to...

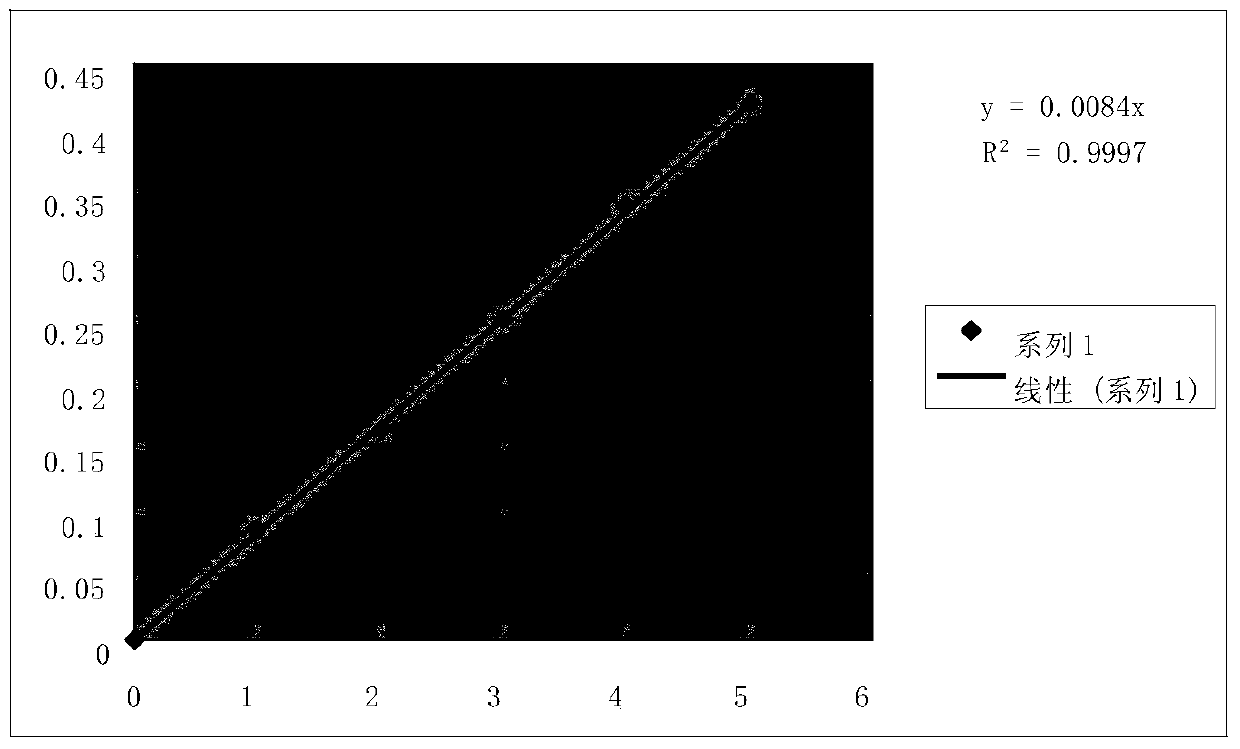

Embodiment 2

[0082] 3 sample test material

[0083] Weigh 0.1998 g sample material, accurate to 0.0001 g.

[0084] 4 Preparation of test solution

[0085]4.1 Put the sample (3) in a 150 mL polytetrafluoroethylene beaker, add 10 mL of nitric acid (2.1), dropwise add 2 mL of hydrofluoric acid (2.3), heat at low temperature until the sample dissolves, cool slightly, add 25 mL of sulfuric acid (2.5), heat at low temperature until the volume of the solution is about 20mL, remove it, transfer it into a 250mL beaker, heat until sulfuric acid fumes are emitted, and heat until the first sulfuric acid fumes are emitted for about 3~4min, remove the beaker and cool slightly, and then pour into the beaker Blow in a small amount of water, heat until the second sulfuric acid fume is emitted for about 2~3 minutes, cool, add 20 mL tartaric acid solution (2.6), 5 mL ammonium fluoride solution (2.7), boil for 2~3 minutes, take it off, add 10 Continue to boil mL of saturated boric acid solution (2.8), cool ...

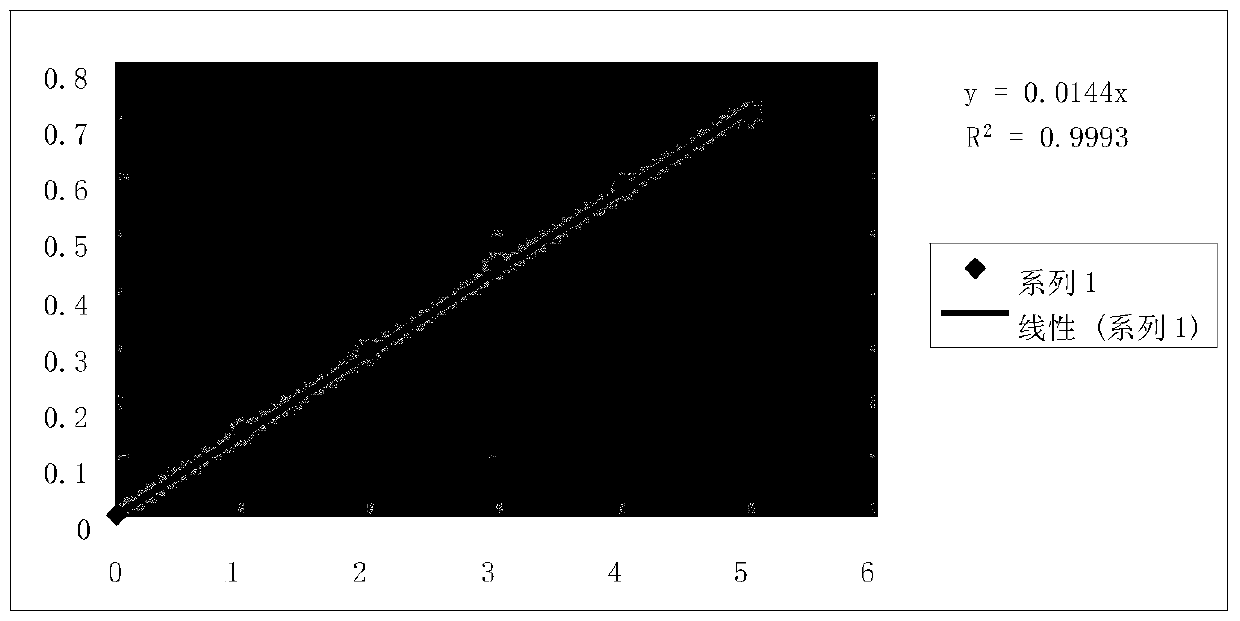

Embodiment 3

[0102] 3 samples

[0103] Weigh 0.1502g sample material, accurate to 0.0001g.

[0104] 4 Preparation of test solution

[0105] 4.1 Put the sample (3) in a 150 mL polytetrafluoroethylene beaker, add 8 mL of nitric acid (2.1), dropwise add 2 mL of hydrofluoric acid (2.3), heat at low temperature until the sample dissolves, cool slightly, add 23 mL of sulfuric acid (2.5), heat at low temperature until the volume of the solution is about 20mL, remove it, transfer it into a 250mL beaker, heat until sulfuric acid fumes are emitted, and heat until the first sulfuric acid fumes are emitted for about 3~4min, remove the beaker and cool slightly, and then pour into the beaker Blow in a small amount of water, heat until the second sulfuric acid fume is emitted for about 2~3 minutes, cool, add 20 mL tartaric acid solution (2.6), 5 mL ammonium fluoride solution (2.7), boil for 2~3 minutes, take it off, add 10 Continue to boil mL of saturated boric acid solution (2.8), cool to room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com