Separation method for flake graphite based on air flow separation and flotation

A technology of airflow separation and flake graphite, which is applied in chemical instruments and methods, flotation, solid separation, etc., can solve the problems of reducing the yield of flake graphite, high management and production costs, and reducing enterprise profit margins, etc., to achieve economic benefits Significant, less environmental pollution, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

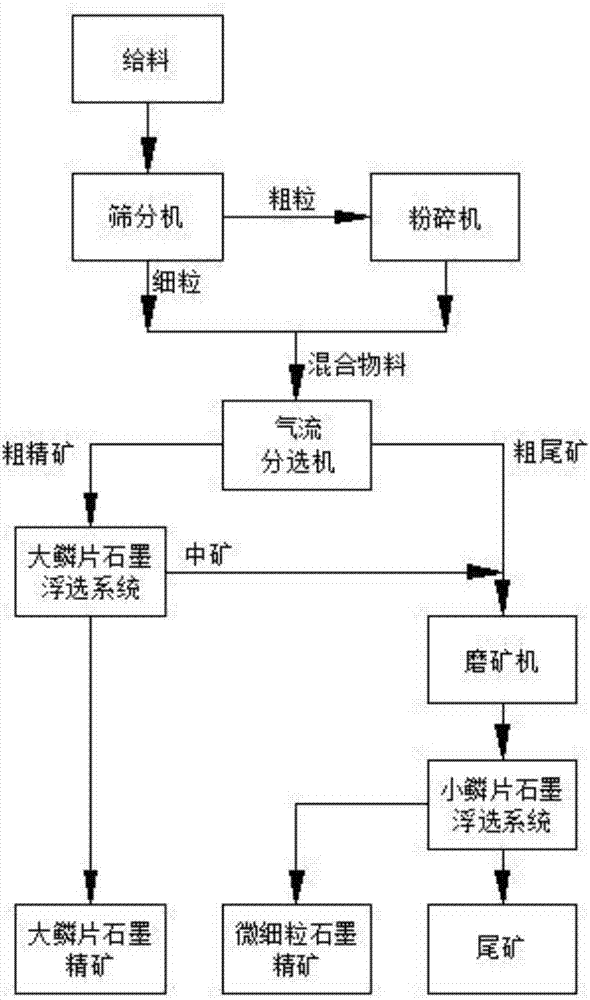

[0023] The present embodiment provides a kind of flake graphite ore sorting method, see attached figure 1 . The steps are as follows:

[0024] (1) Feed the graphite mineral material containing flake graphite into the sieving machine and classify, and separate the coarse-grained product on the sieve and the fine-grained product under the sieve;

[0025] (2) Feed the coarse-grained product on the sieve into the pulverizer for pulverization, and the pulverized material is discharged from the discharge port;

[0026] (3) mixing the pulverized material with the fine-grained product under the sieve to obtain a mixed material;

[0027] (4) The mixed material is fed into the airflow separator and sorted to obtain rough concentrate and rough tailings;

[0028] (5) Feed the rough concentrate into the large flake graphite flotation system for flotation, and sort out the large flake graphite concentrate product and medium ore product;

[0029] (6) After mixing the medium ore product a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com