Graphene impermeable agent, preparation method thereof and applications thereof

A graphene and anti-seepage agent technology, which is applied in the field of anti-seepage materials and anti-seepage agents containing graphene, can solve the problems of large amount of graphene nanosheets added, which is not conducive to the dispersion of graphene, and limits practical applications, etc., and achieves high Strength, high flexibility, and good complementary advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

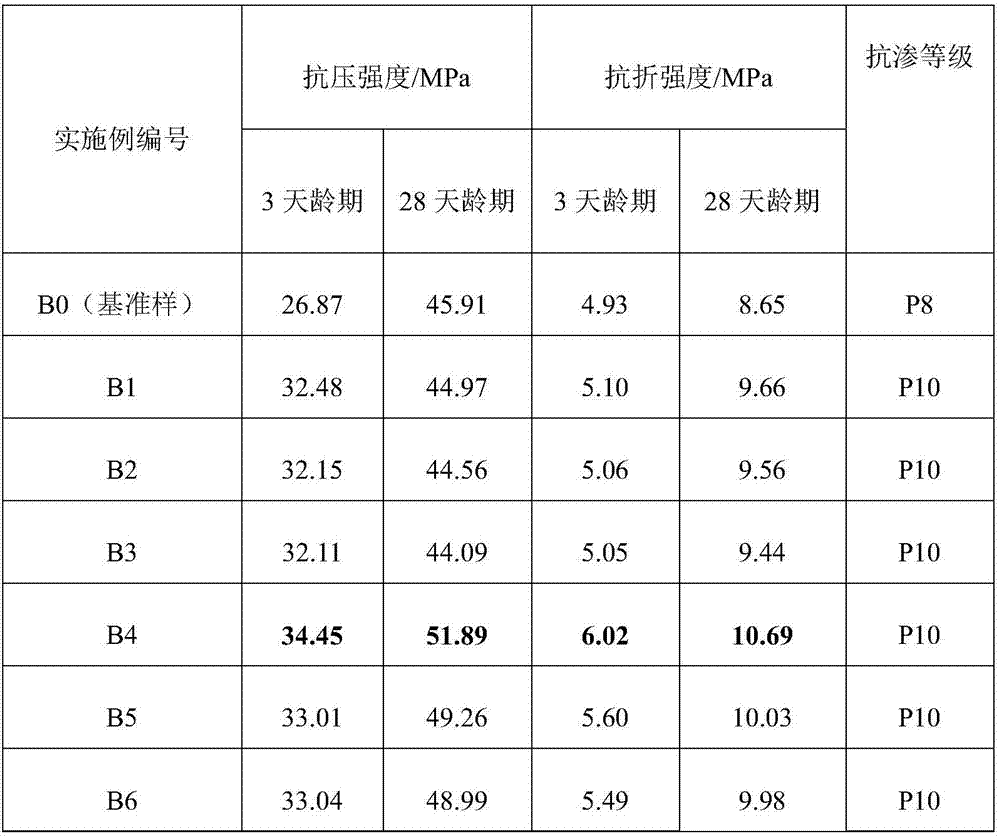

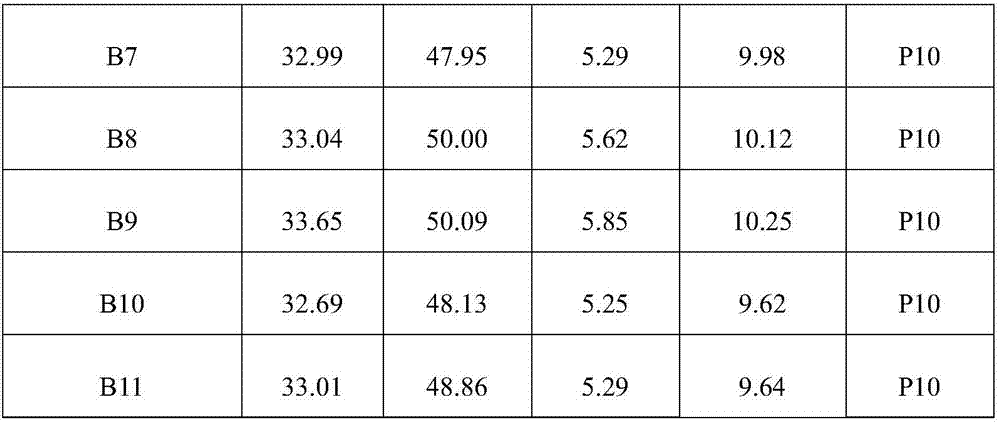

Examples

Embodiment 1

[0055] (1) Weigh 5g graphene and 250g water, after stirring evenly, add 15g triethanolamine in this graphene aqueous suspension, stir uniformly, obtain the mixed slurry of graphene, water and triethanolamine. Then, the above-mentioned mixed slurry was ground for 1 hour in a sand mill disperser with a rotation speed of 1500 rpm. After the grinding is completed, the above mixed slurry is reacted for 50 minutes at 45° C. and the rotation speed is 500 rpm. After the reaction is completed, the mixed slurry of graphene / triethanolamine is obtained.

[0056] (2) 40g fly ash (30g class I fly ash, 10g class II fly ash), 30g silicon powder (18g 12500 mesh silicon powder, 12g 5000 mesh silicon powder), 6g gypsum (calcined at a temperature of 120°C ) dry-mixed in a ball mill to obtain a mixed powder.

[0057] (3) Place the mixed slurry obtained in step (1) in a heated spray dryer at 100° C., and spray the mixed slurry evenly into the mixed powder obtained in step (2) to obtain a mixed pow...

Embodiment 2

[0060] (1) Weigh 10g graphene and 1000g water, after stirring evenly, add 13g triethanolamine and 10g diethanolamine in this graphene aqueous suspension, stir evenly, obtain graphene mixed slurry. Then, the above-mentioned mixed slurry was ground for 1.5 hours in a sand mill disperser with a rotation speed of 1800 rpm. After the grinding is completed, the above mixed slurry is reacted for 45 minutes at 50° C. and the rotation speed is 800 rpm. After the reaction is completed, a mixed slurry of graphene / triethanolamine / diethanolamine is obtained.

[0061] (2) Dry-mix 30g of fly ash (15g of Class I fly ash, 15g of Class II fly ash), 10g of ultrafine slag powder, and 8g of gypsum (calcined at a temperature of 130°C) in a ball mill to obtain a mixed powder .

[0062] (3) Place the mixed slurry obtained in step (1) in a heated spray dryer at 115° C., and spray the mixed slurry evenly into the mixed powder obtained in step (2) to obtain a mixed powder with evenly dispersed graphene...

Embodiment 3

[0065] (1) take 8g graphene and 1100g water by weighing, after stirring, add 15g triethanolamine and 10g diethanol monoisopropanolamine in this graphene aqueous suspension, stir, obtain graphene and water and alcohol amine Mix slurry. Then, the above-mentioned mixed slurry was ground for 1 hour in a sand mill disperser with a rotation speed of 2000 rpm. After the grinding is completed, the above mixed slurry is reacted for 60 minutes under the conditions of 50° C. and a rotation speed of 900 rpm. After the reaction is completed, the mixed slurry of graphene / alcoholamine is obtained.

[0066] (2) 25g fly ash (22g I grade fly ash, 3g II grade fly ash), 20g silicon powder (15g 12500 mesh silicon powder, 5g 2000 mesh silicon powder), 10g ultrafine slag powder, 7g gypsum ( Calcined at a temperature of 150° C.) dry-mixed in a ball mill to obtain a mixed powder.

[0067] (3) Place the mixed slurry obtained in step (1) in a heated spray dryer at 120° C., and spray the mixed slurry e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com