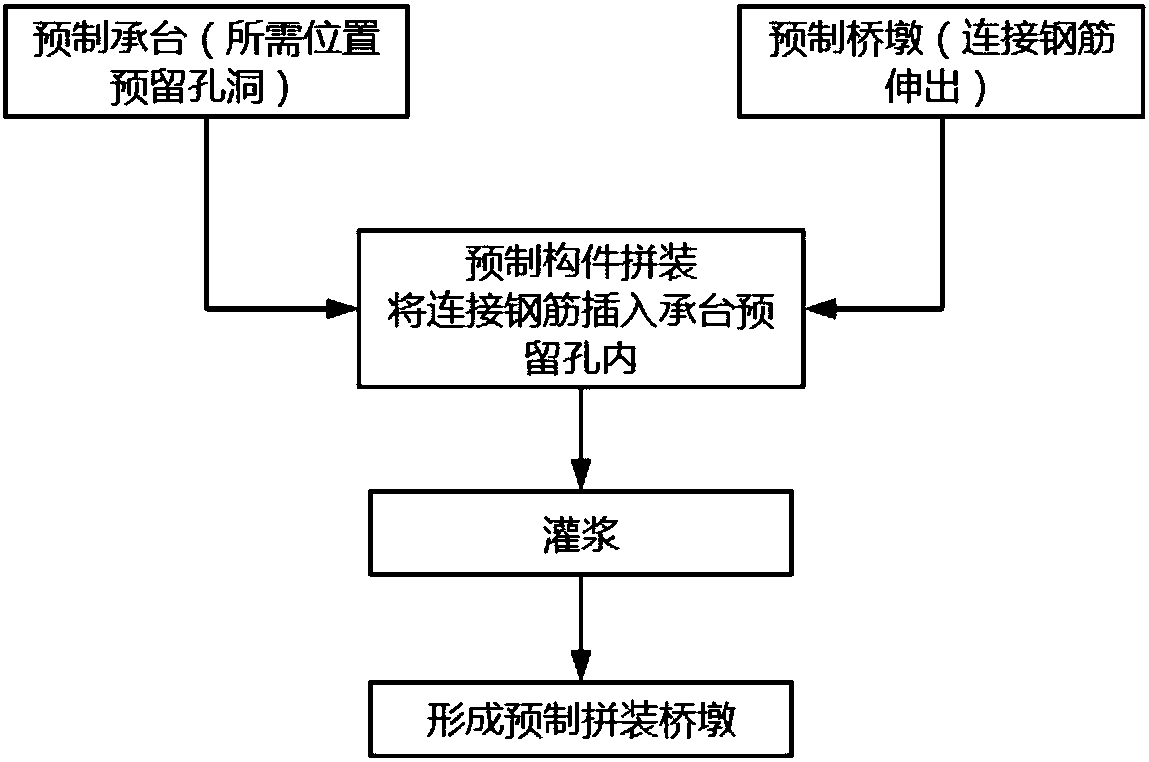

Connection method of reserved grouting holes for prefabricated assembled bridge piers

A technology of prefabricated assembly and connection method, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problem of high production cost of grouting sleeves or metal bellows, easy corrosion of grouting sleeves or metal bellows, and weakening of connecting steel bars. Anchoring ability and other issues, to overcome the corrosion problem, enhance the connection reliability, and the effect of strong connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

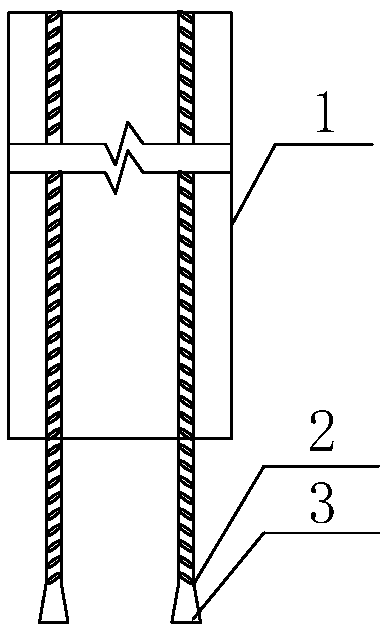

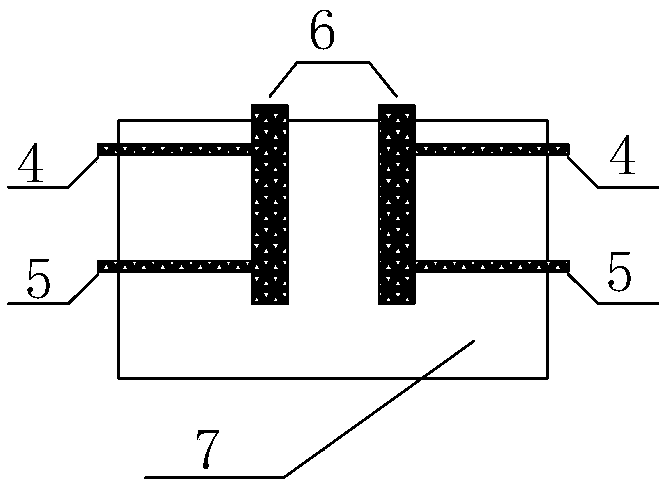

Examples

Embodiment 1

[0043] Among them, the raw material composition of the grouting material (special grouting material) is as follows:

[0044] Ordinary Portland cement: 52.5 ordinary Portland cement with a specific surface area greater than 300m 2 / Kg, 80um square hole sieve residue is less than 10%; sulphoaluminate cement: 42.5 sulphoaluminate cement, specific surface area greater than 350m 2 / Kg, the sieve residue of 80um square hole is less than 10%, the initial setting time is less than 25min, and the 1d compressive strength is greater than 30MPa; Quartz sand; fly ash: Class I fly ash; water reducer: polycarboxylate ether powder high-efficiency water reducer; composite expansion agent: concrete anti-seepage and anti-crack expansion agent UEA; activator: lithium hydroxide.

[0045] The distribution ratio of each component of the grouting material is: 45 parts of 52.5 ordinary portland cement; 15 parts of 42.5 sulfoaluminate cement; 30 parts of continuous graded quartz sand; 10 parts of grad...

Embodiment 2

[0054] The raw material composition of the grouting material (special grouting material) used is as follows:

[0055] 50 parts of 52.5 ordinary portland cement; 10 parts of 42.5 sulfoaluminate cement; 35 parts of continuous graded quartz sand; 15 parts of grade I fly ash; 0.2 parts of polycarboxylate ether powdery superplasticizer; 3 parts of agent; 0.2 parts of lithium hydroxide.

[0056] During construction, it is mixed on site according to the water-to-material ratio of 0.35, and it is used after stirring evenly.

[0057] According to the measurement method of GB / T 50448 "Technical Specifications for the Application of Cement-based Grouting Materials", the properties of the special grouting materials measured are as follows:

[0058] Initial fluidity: 350; 30min: 300;

[0059] Vertical free expansion rate (3d): 0.18;

[0060] Compressive strength 1d: 46MPa; 3d: 62MPa; 28d: 85MPa;

[0061] Grip strength (round steel) ≥ 5MPa.

Embodiment 3

[0063] The raw material composition of the grouting material (special grouting material) used is as follows:

[0064] 40 parts of 52.5 ordinary portland cement; 15 parts of 42.5 sulfoaluminate cement; 30 parts of continuous graded quartz sand; 15 parts of grade I fly ash; 2 parts of agent; 0.1 part of lithium hydroxide.

[0065] During construction, it is mixed on site according to the water-to-material ratio of 0.4, and it is used after stirring evenly.

[0066] According to the measurement method of GB / T 50448 "Technical Specifications for the Application of Cement-based Grouting Materials", the properties of the special grouting materials measured are as follows:

[0067] Initial fluidity: 360; 30min: 305;

[0068] Vertical free expansion rate (3d): 0.15;

[0069] Compressive strength 1d: 45MPa; 3d: 60MPa; 28d: 85MPa;

[0070] Grip strength (round steel) ≥ 5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com