Silver nanowire transparent conductive thin film and preparation method thereof

A technology of transparent conductive film and silver nanowires, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, conductive materials dispersed in non-conductive inorganic materials, etc. Over-rate, increase square resistance and other issues, to achieve the effect of reducing square resistance, tight contact, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

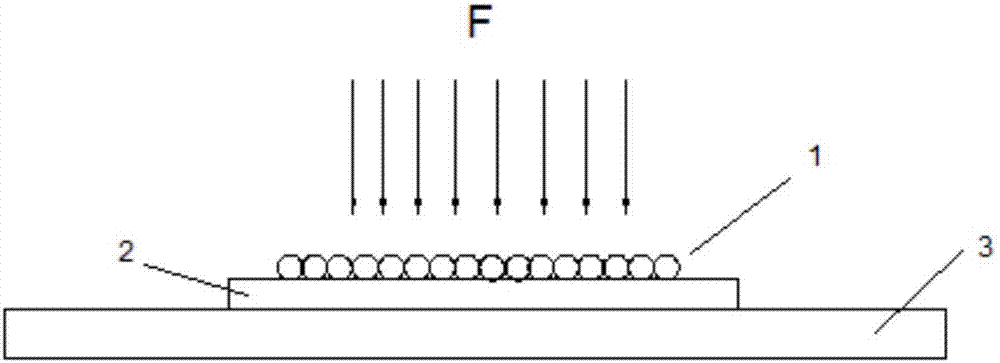

[0026] The embodiment of the present invention also provides a method for preparing the above-mentioned silver nanowire transparent conductive film, comprising the following steps:

[0027] Ultrasonic cleaning of flexible substrates;

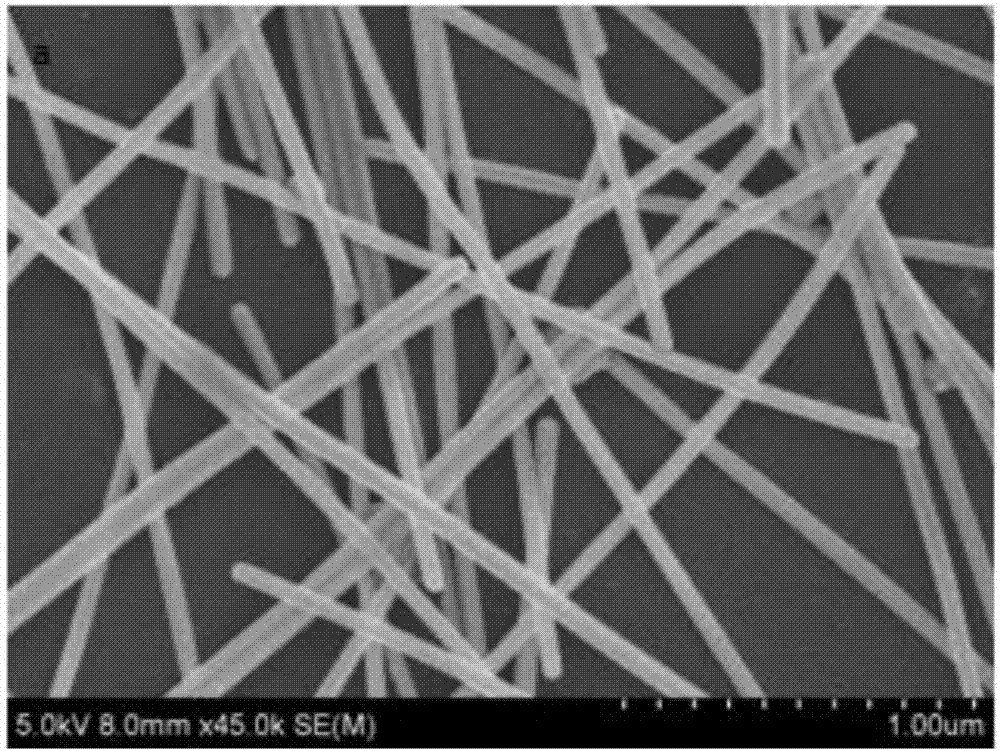

[0028] Dispersing the silver nanowires in a solvent to form a silver nanowire dispersion, uniformly coating the silver nanowire dispersion on a flexible substrate, and drying to obtain a silver nanowire conductive layer;

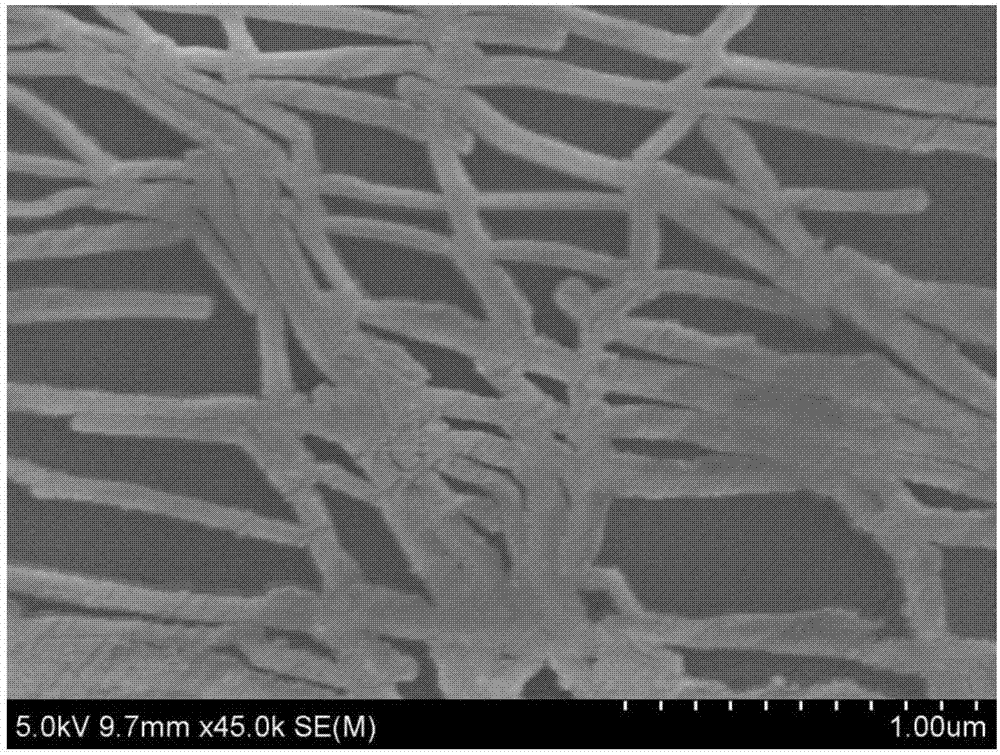

[0029] The obtained silver nanowire conductive layer is subjected to hot-pressing treatment, so that the nano silver wire is plastically deformed and welded, and a flattened and connected silver nanowire transparent conductive film is obtained.

[0030] In the preparation method of the silver nanowire transparent conductive film provided by the embodiment of the present invention, the silver nanowire conductive layer is mechanically embedded on the surface of the flexible substrate by hot pressing, so that the silver nanowire ...

Embodiment 1

[0041] Select polyethylene terephthalate as a flexible substrate, and dry it after hydrophilic treatment; uniformly disperse silver nanowires in ethanol solution, and prepare a silver nanowire solution with a concentration of 0.5g / L; The silver nanowire solution is uniformly coated on the flexible substrate by spin coating, the spin coating speed is 3500r / min, and the drying time is 30s to obtain the silver nanowire conductive layer; the flexible substrate after spin coating is placed on the heating plate for Hot press treatment, the temperature of the heating plate is 100°C, the applied pressure is 1.5 bar, and the time is 10s. The light transmittance of the silver transparent conductive film after hot pressing was 86.5%, the square resistance was 47.6Ω / square, and the haze was 7.2.

Embodiment 2

[0043] Select polyethylene terephthalate as a flexible substrate, carry out hydrophilic treatment on it and then dry it; uniformly disperse the silver nanowires in the ethanol solution, and prepare a silver nanowire solution with a concentration of 1.0g / L; The silver nanowire solution is uniformly coated on the flexible substrate by spin coating, the spin coating speed is 3500r / min, and the drying time is 30s to obtain the silver nanowire conductive layer; the flexible substrate after spin coating is placed on the heating plate for Hot press treatment, the temperature of the heating plate is 120°C, the applied pressure is 2.0 bar, and the time is 10s. The light transmittance of the silver transparent conductive film after hot pressing was 85.7%, the square resistance was 41.8Ω / square, and the haze was 10.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com