NCA@metal oxide/carbon nano-tubes (CNT) composite cathode material and preparation method and application thereof

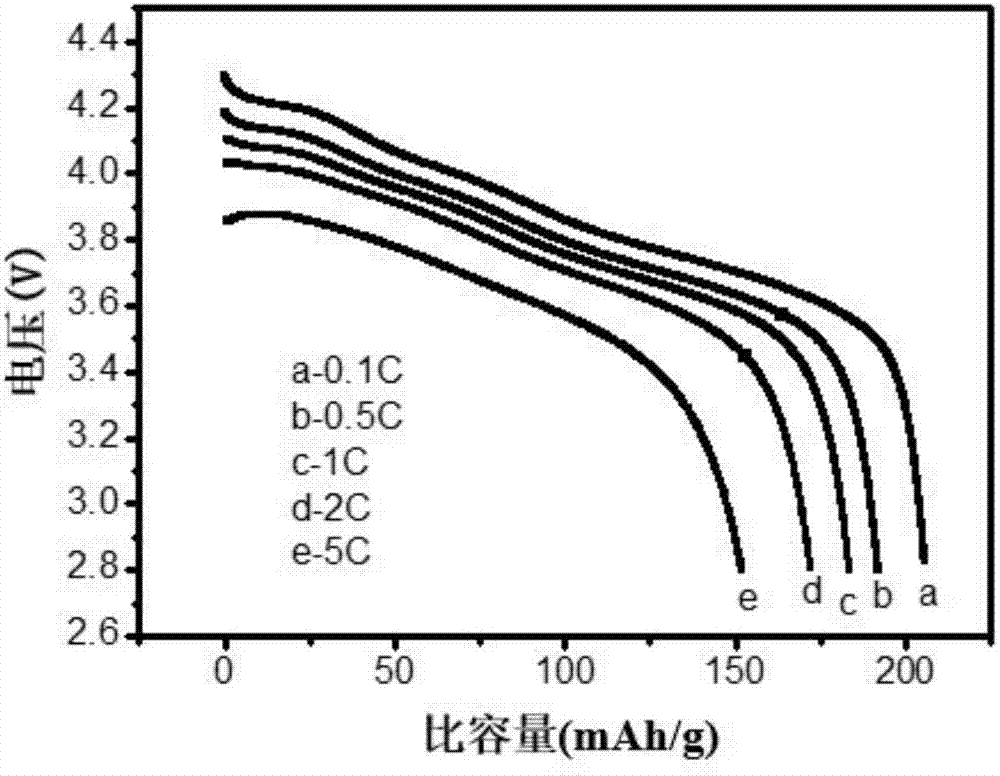

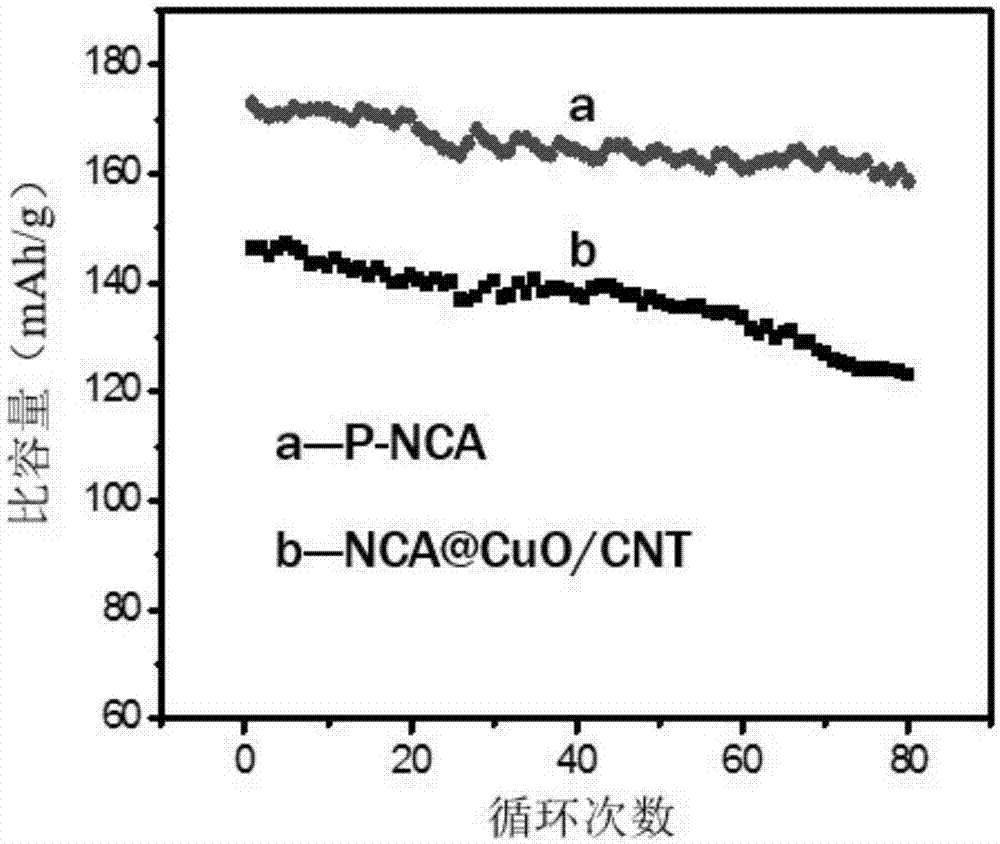

A carbon nanotube composite and composite positive electrode material technology, which is applied in the direction of positive electrodes, active material electrodes, battery electrodes, etc., can solve the problems of poor thermal stability, poor rate performance, and poor cycle performance of ternary positive electrode materials, and achieve improved electrochemical performance. And thermal stability, improve electrical conductivity, reduce the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Dissolve nickel nitrate, cobalt nitrate, and aluminum nitrate in deionized water at a molar ratio of 8:1.5:0.5, mix them evenly, inject them into a continuous mixer filled with argon, and then slowly drop them into the mixed lye of sodium hydroxide and ammonia water to control The pH value of the solution is 10, and as the reaction proceeds, a precursor of nickel-cobalt-lithium-aluminate cathode material is prepared.

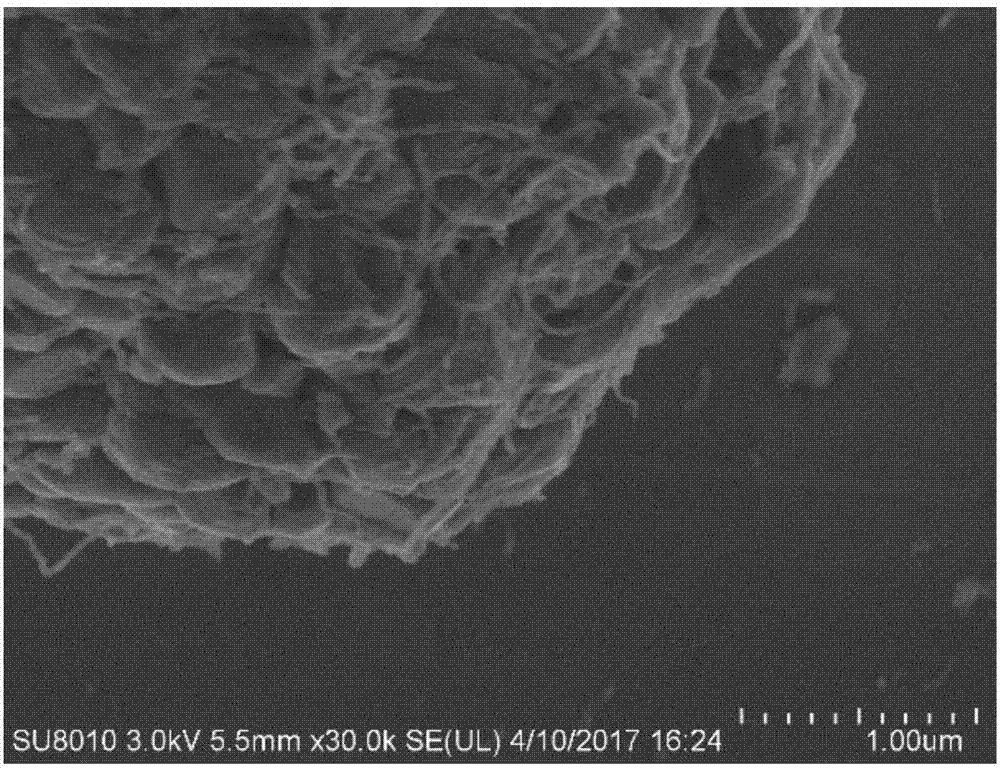

[0035] 2. Dissolve 1 mol of copper nitrate in absolute ethanol and stir until it is completely dissolved; then weigh the nickel-cobalt-lithium-aluminate cathode material precursor whose molar number is 99 times that of the metal salt, add it, and stir at room temperature for 1 hour at a speed of 300 rpm ; Finally, place the above-mentioned nickel-cobalt-lithium-aluminate cathode precursor / metal salt ethanol solution in a drying oven and dry it; and make a nickel-cobalt-lithium-aluminate cathode precursor / copper nitrate composite material.

[0036] 3. M...

Embodiment 2

[0040] 1. Dissolve nickel nitrate, cobalt nitrate, and aluminum nitrate in deionized water at a molar ratio of 8:1.5:0.5, mix them evenly, inject them into a continuous mixer filled with argon, and then slowly drop them into the mixed lye of sodium hydroxide and ammonia water to control The pH value of the solution is 11, and as the reaction progresses, a precursor of nickel-cobalt-lithium-aluminate cathode material is prepared.

[0041] 2. Dissolve 1 mol of magnesium nitrate in absolute ethanol and stir until completely dissolved; then weigh the nickel-cobalt-lithium-aluminate cathode material precursor whose molar number is 98 times that of the metal salt, add it, and stir at room temperature for 2 hours at a speed of 400 rpm ; Finally, place the above-mentioned nickel-cobalt-lithium-aluminate cathode precursor / metal salt ethanol solution in a drying oven and dry it; and make a nickel-cobalt-lithium-aluminate cathode precursor / magnesium nitrate composite material.

[0042] 3...

Embodiment 3

[0045] 1. Dissolve nickel nitrate, cobalt nitrate, and aluminum nitrate in deionized water at a molar ratio of 8:1.5:0.5, mix them evenly, inject them into a continuous mixer filled with argon, and then slowly drop them into the mixed lye of sodium hydroxide and ammonia water to control The pH value of the solution is 10, and as the reaction proceeds, a precursor of nickel-cobalt-lithium-aluminate cathode material is prepared.

[0046] 2. Dissolve 1 mol of copper nitrate in methanol and stir until it is completely dissolved; then weigh the nickel-cobalt-lithium-aluminate cathode material precursor whose molar number is 95 times that of the metal salt, add it, and stir at room temperature for 3 hours at a speed of 500 rpm; finally The above nickel-cobalt-lithium-aluminate cathode precursor / metal salt ethanol solution is placed in a drying oven and dried to prepare a nickel-cobalt-lithium-aluminate cathode precursor / copper nitrate composite material.

[0047] 3. Mix the nickel-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com