Efficient energy-saving gasoline product

A high-efficiency, energy-saving, gasoline technology, applied in the field of gasoline additives, can solve the problems of increased engine compression ratio, increased engine fuel consumption, unsatisfactory efficiency, etc., and achieves the effects of reducing friction, reducing maintenance, and efficient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

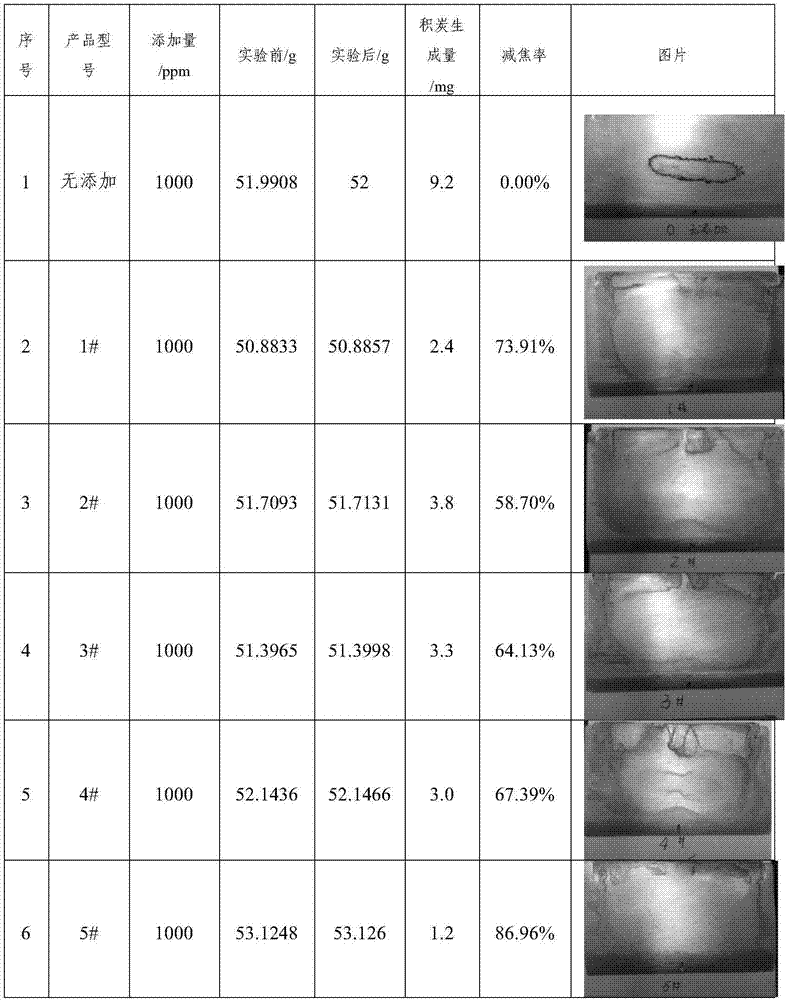

Examples

preparation example Construction

[0038] A kind of preparation method of high-efficiency and energy-saving gasoline product:

[0039] According to the selected weight ratio, the components are blended at room temperature to 60°C. First, catalytic gasoline, reformed gasoline, hydrogen gasoline, pentane oil, and alkylated gasoline are placed in the reactor and heated at a constant temperature with a steam jacket. Then add highly active polyisobutene amine and high active polyether amine in sequence. After fully stirring for 10-15 minutes, the viscosity of the product will not change. Then add carrier agent, anti-rust agent and friction agent in sequence, and stir for 15-20 minutes After mixing evenly, an emulsified product is obtained. Finally, the demulsification additive is added, and the product is stirred until the emulsification is eliminated and the phenomenon of complete stratification can appear after standing still to obtain the final product.

Embodiment 1

[0041] The content of each component is: catalytic gasoline 20%, reformed gasoline 12%, hydrogen gasoline 35%, pentane oil 10%, alkylated gasoline 15%, diamine polyisobutene amine 0.9%, pentaamine polyisobutene amine 1.6%, nonylphenol polyetheramine 1.5%, quaternized polyetheramine 2.57%, polyether 1.4%, mineral oil 1.4%, polyalphaolefin 0.3%, succinimide 0.17%, succinamide compound 0.05%, 0.08% fatty acid amine salt, 0.01% chlorate, 0.01% bromate, 0.01% persulfate, among which R 1 for CH 3 , R 2 for C 2 h 5 and R 3 for C 3 h 7 , n=10, m=3, the product prepared according to the preparation method is marked as 1#.

Embodiment 2

[0043] The content of each component is: diamine polyisobutene amine 1.1%, pentaamine polyisobutene amine 1.4%, nonylphenol polyetheramine 1.5%, quaternized polyetheramine 2.57%, polyether 1.4%, mineral oil 1.4% %, polyalphaolefin 0.3%, succinimide 0.17%, succinamide compound 0.05%, fatty acid amine salt 0.08%, chlorate 0.01%, bromate 0.01%, persulfate 0.01%, other conditions and examples 1 is the same, and the resulting product is marked as 2#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com