Dyeing method for micro-arc treatment metal workpiece

A technology of metal workpieces and dyeing methods, applied in the field of dyeing, can solve the problems of affecting the assembly precision or reliability, losing the mechanical properties of ceramic texture of micro-arc oxidation layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

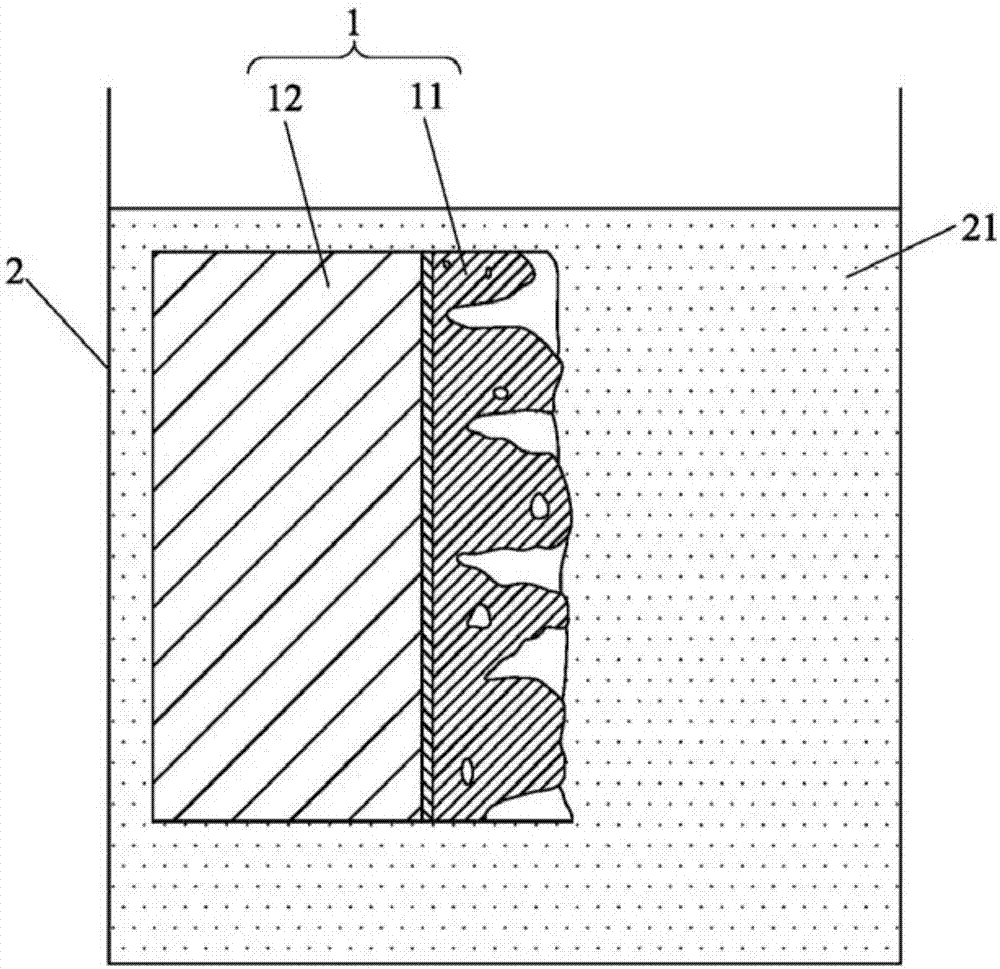

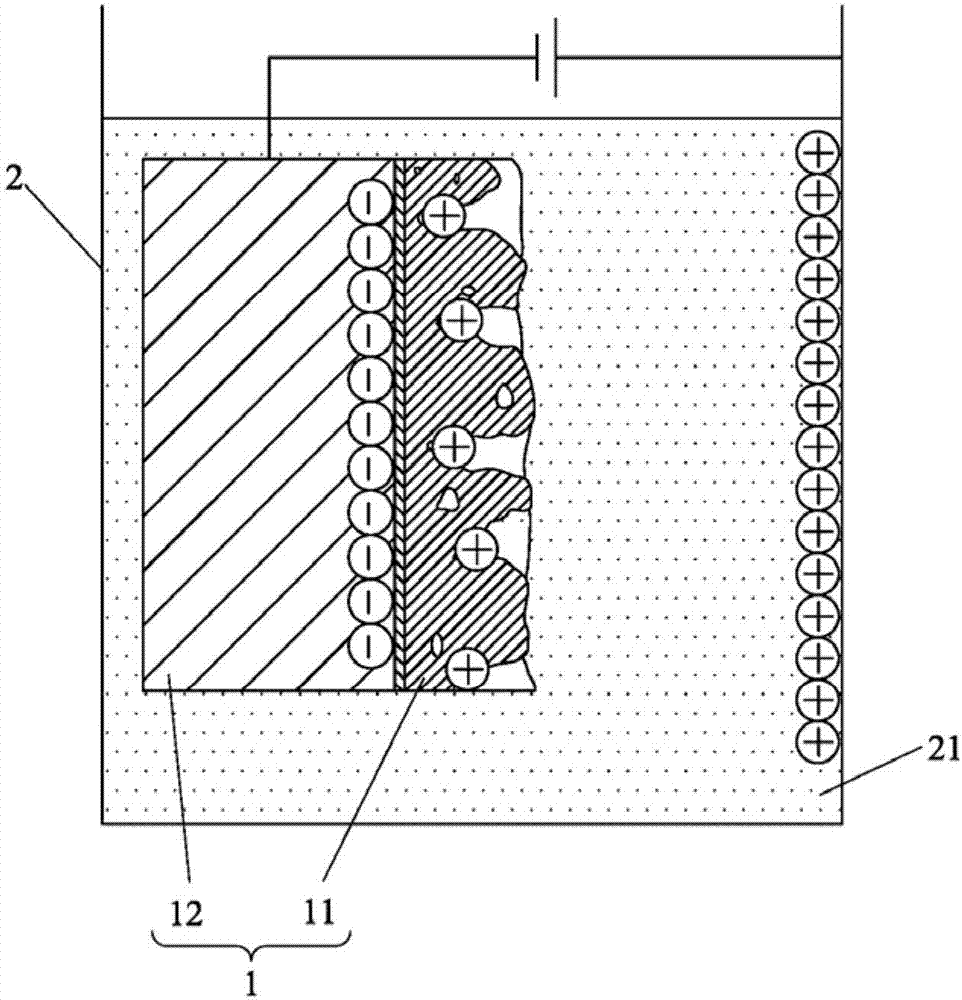

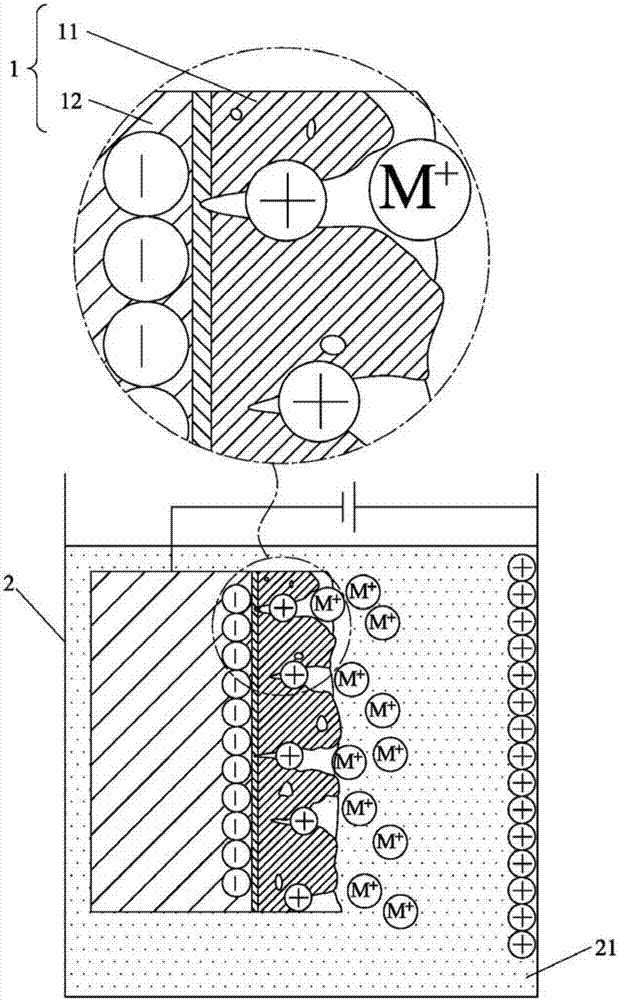

[0044] see Figure 1a to Figure 1d As shown, it is a schematic diagram of the pretreatment of the dyeing method of the micro-arc treatment metal workpiece of the present invention. see Figure 2a to Figure 2d Shown is a schematic diagram of the dyeing process of the dyeing method of the micro-arc treatment metal workpiece of the present invention.

[0045] The micro-arc treated metal workpiece 1 is composed of a metal substrate 12 and a micro-arc oxidation layer 11 obtained after micro-arc treatment, and has a first color, or uses other alloys as the metal substrate, but is not limited thereto. The micro-arc oxidation layer 11 is a membranous structure with a large number of open and closed pores in the micron scale.

[0046] A dyeing method for micro-arc processing metal workpieces, comprising the following steps:

[0047] (1) Pretreatment

[0048] (11) If Figure 1a As shown, first add the pretreatment solution 21 into the reaction tank 2, then put the micro-arc treated ...

specific Embodiment 2

[0068] Roughly the same as the specific example 1, the difference is only that the green anionic organic dye is used, and the dyeing of the metal workpiece by micro-arc treatment is carried out according to the method of the specific example 1, and the dyeing result is as follows Figure 4b And as shown in Table 1, the chromaticity value (L*a*b*)=(75.93,-2.59,35.63) of the micro-arc treated metal workpiece 1b treated with the green anionic organic dye.

specific Embodiment 3

[0069] Roughly the same as the specific example 1, the difference is only that the blue anionic organic dye is used, and the method for micro-arcing the metal workpiece is dyed according to the method of example 1, and the dyeing result is as follows Figure 4c As shown in Table 1, the chromaticity value of the micro-arc treated metal workpiece 1c treated with the blue anionic organic dye is (L*a*b*)=(52.48, 2.98, -36.48).

[0070] To sum up, the present invention proposes a dyeing method for micro-arc treatment of metal workpieces, hoping to provide a different way of thinking and practice for the industry to apply this coloring technology. The technical solution of the present invention includes pretreatment and dyeing treatment, through these two steps, the dyestuff can be effectively attached to the micro-arc oxidation layer to achieve the effect of dyeing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com