Box-type thin-walled part milling stability prediction method

A technology of stability prediction, thin-walled parts, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

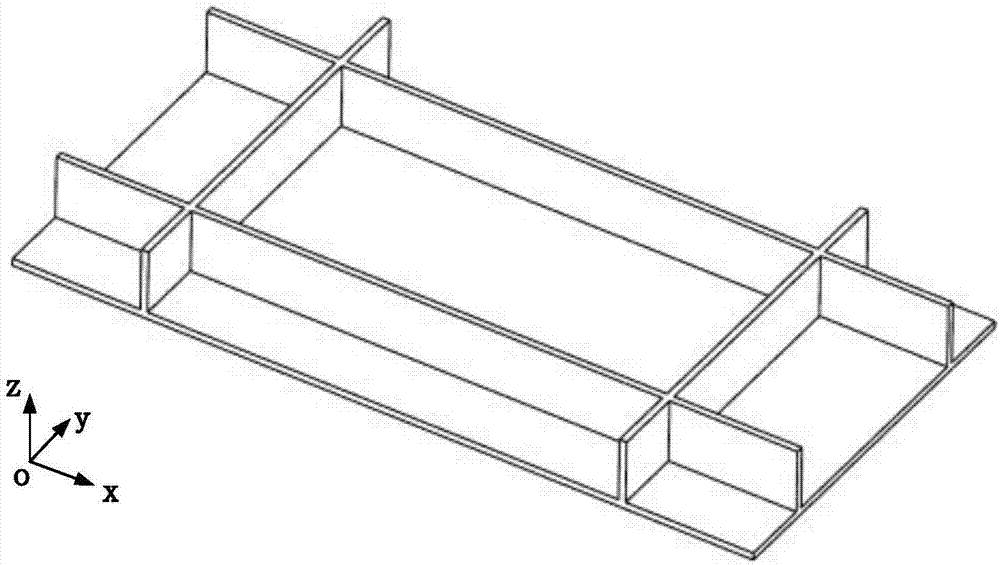

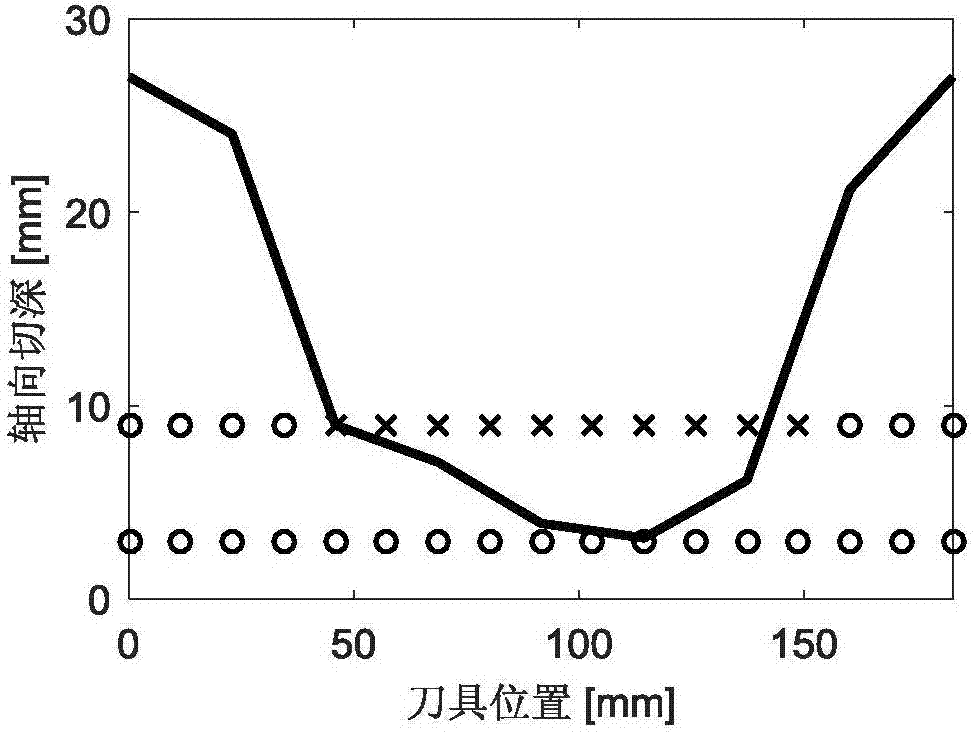

[0046] Embodiment 1: Adopt the present invention to carry out the prediction of the peripheral milling stability of the box-shaped thin-walled part that the side wall is all plane, wherein the box-shaped size is 200mm * 100mm * 27mm, the thickness of the bottom of the box is 3mm, the thickness of the side wall before milling is 3mm, and the diameter The depth of cut is 1mm, the material of the workpiece is aluminum alloy 7050, and the workpiece is clamped on the machine table by the pressure plate.

[0047] (1) Clamp a 3-tooth flat-end end mill with a diameter of 16mm on the spindle of the machine tool through a collet holder, the tool extension length is 50mm, and the tool material is cemented carbide; the tool-tool holder-spindle system is modal Hammering experiment, the frequency response function of three points along the tool axis is measured, and the tool-tool holder-spindle system is experimentally analyzed through the three-point frequency response function, and the nat...

Embodiment 2

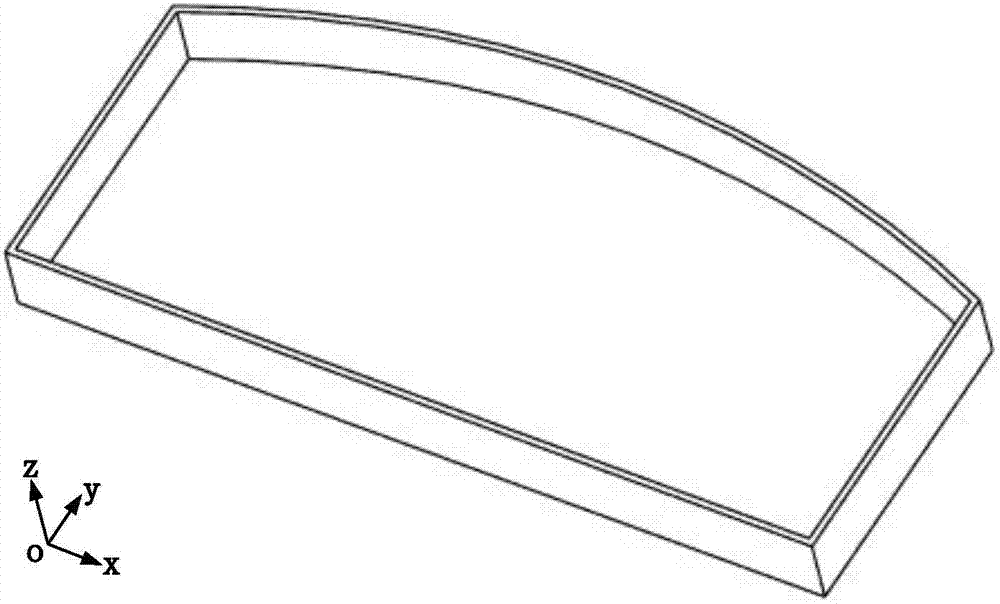

[0078] Embodiment 2: Adopt the present invention to carry out the prediction of the milling stability of the box-shaped thin-walled part with curved surface on the side wall, one side wall of this box-shaped part is a curved surface, and the surface equation is

[0079] x(u,v)=R W cos(θ W +(u-1)(2θ W -π))

[0080] y(u,v)=R W sin(θW +(u-1)(2θ W -π))+0.155-R W u,v∈[0,1]

[0081] z(u,v)=28v

[0082] Among them, θ W = 1.164705892287963 rad, R W =0.43035714285714m, the unit of x, y, z is m. The other 3 side walls are plane. The size of the box is 340mm×155mm×28mm, the thickness of the bottom of the box is 2mm, the wall thickness before milling is 2.8mm, the radial cutting depth is 1mm, the material of the workpiece is aluminum alloy 7050, and the workpiece is clamped on the machine table by the pressure plate.

[0083] (1) Clamp a 3-tooth flat-end end mill with a diameter of 16mm on the spindle of the machine tool through a collet holder, the tool extension length is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com