Nitrogen and phosphor-doped carbon-based nonmetallic oxygen reduction/separation double-effect catalyst and preparation method thereof

A co-doping, non-metallic technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of high cost, difficulty in large-scale promotion, poor stability, and low catalytic performance of secondary metal-air battery catalysts, and achieve high-efficiency oxygen Effects of precipitation reaction catalytic performance, mild synthesis conditions, and good double-effect electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

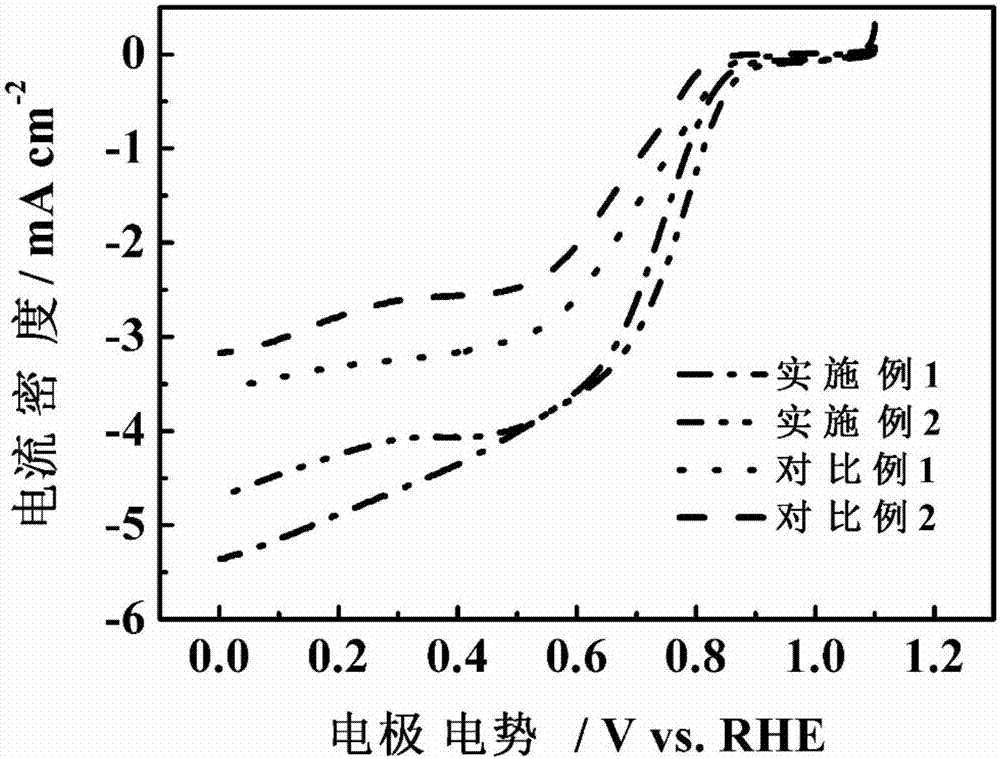

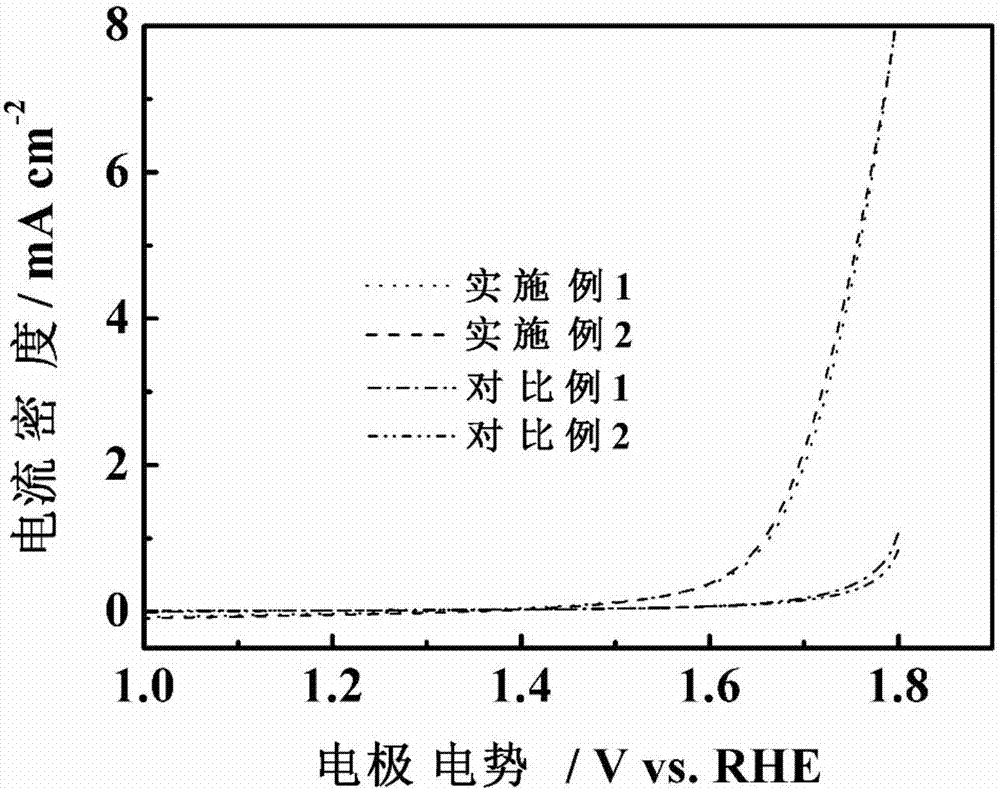

Embodiment 1

[0029] Weigh 0.238g (0.907mmol) of triphenylphosphine, 0.180g (1.428mmol) of melamine, and 0.060g of graphene oxide into 20ml of tetrahydrofuran, ultrasonically mix, then transfer to a 50ml reactor, heat up to 110°C, and react 24 hours.

[0030] The resulting product was washed with deionized water and ethanol for several times, and dried in an oven at 60°C for 12 hours. Carbon-based materials containing nitrogen and phosphorus are obtained. The synthesized nitrogen- and phosphorus-containing carbon-based materials were moved into a high-temperature furnace for calcination, with a flow rate of 100mL min -1 Argon gas, the high temperature furnace is heated up to 350°C at a rate of 5-10°C / min, held for 2 hours, then heated to 900°C, and then cooled naturally after holding for 2 hours to form a nitrogen-phosphorus co-doped carbon-based double-effect catalyst.

Embodiment 2

[0032] Weigh 0.190g (0.546mmol) of hexachlorotrimeric phosphazene, 0.200g (1.587mmol) of melamine, and 0.060g of carbon nanotubes into 20ml of tetrahydrofuran, mix well by ultrasonic, then transfer to a 50ml reaction kettle, and heat up to 120°C , reacted for 24 hours.

[0033] The resulting product was washed with deionized water and ethanol for several times, and dried in an oven at 70°C for 12 hours. Carbon-based materials containing nitrogen and phosphorus are obtained. The synthesized carbon-based materials containing nitrogen and phosphorus are moved into a high-temperature furnace for calcination, with a flow rate of 100mL min -1 Argon gas, the high temperature furnace is heated up to 350°C at a rate of 5-10°C / min, held for 3 hours, then heated to 950°C, and then cooled naturally after holding for 2 hours to form a nitrogen-phosphorus co-doped carbon-based double-effect catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com