Application of porous frame materials in masks

A porous frame and facial mask technology, which is applied in the fields of material chemistry and skin care products, can solve problems such as insufficient utilization of active substances, skin allergies and inflammation, and general cleaning ability, so as to avoid adverse effects, avoid deactivation, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of MIL-101 matrix:

[0031] Weigh 1.08 g of ferric chloride and 0.66 g of terephthalic acid into a 60 mL airtight glass bottle, and add 40 mL of N,N-diformamide to it for ultrasonication to dissolve the solid to obtain a brownish-yellow solution. The system was placed in an oven and heated at 110°C for 24 hours. After the reaction, the reaction mixture was centrifuged at high speed, and the brown supernatant was discarded to obtain an orange solid, which was washed several times with deionized water. Place in a desiccator and dry at room temperature for 24 hours.

[0032] The solid obtained above was solvent-exchanged with ethanol at a frequency of 4 times a day for three days, and the obtained solid was air-dried at room temperature. Grind and sieve to obtain the cleansing mask MIL-101 matrix.

[0033] Preparation of ZIF-11 preservative:

[0034] Weigh 0.12 g of benzimidazole and place it in a reaction flask, add 4.8 g of ethanol into the reaction flask...

Embodiment 2

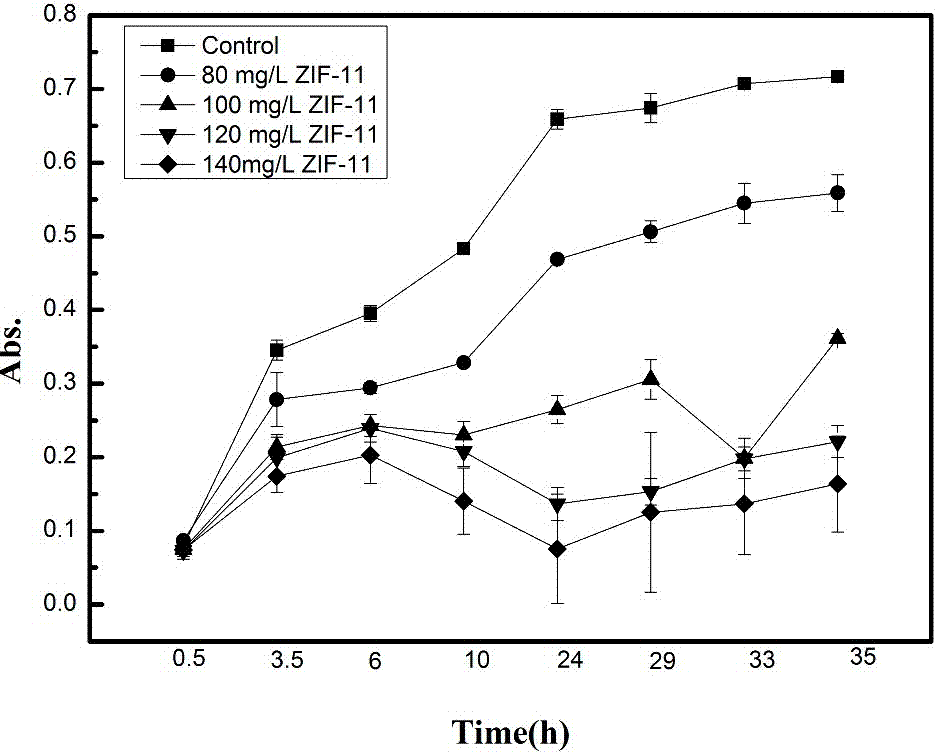

[0036] Cytotoxicity experiment of porous framework materials: Hela and 3T3 cells in exponential phase were collected, and the cell concentration was adjusted to 4×10 4 ~5×10 4 / mL. The experimental wells and control wells were 100 μL of cell suspension, and the blank control wells were the same volume of culture medium. After culturing overnight, the experimental wells were replaced with porous framework material solutions of different concentrations, with 5 to 6 replicate wells for each concentration, and the same volume of culture solution was added to the control wells and blank control wells, and placed in CO 2 After culturing in a constant temperature incubator for 4 hours, suck off the supernatant and wash with PBS 1-2 times. Add 100 μL of culture medium and 10 μL of MTT solution, and continue to incubate for 3 hours. After 3 hours, the supernatant was sucked away, 100 μL of DMSO was added to each well, and placed on a desktop constant temperature shaker at 37°C and 8...

Embodiment 3

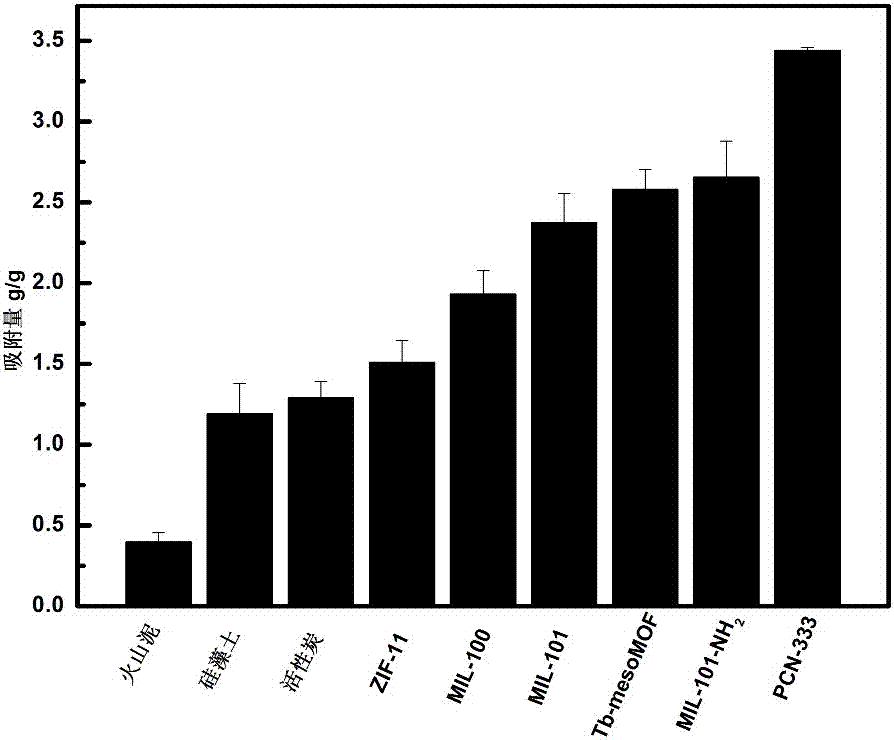

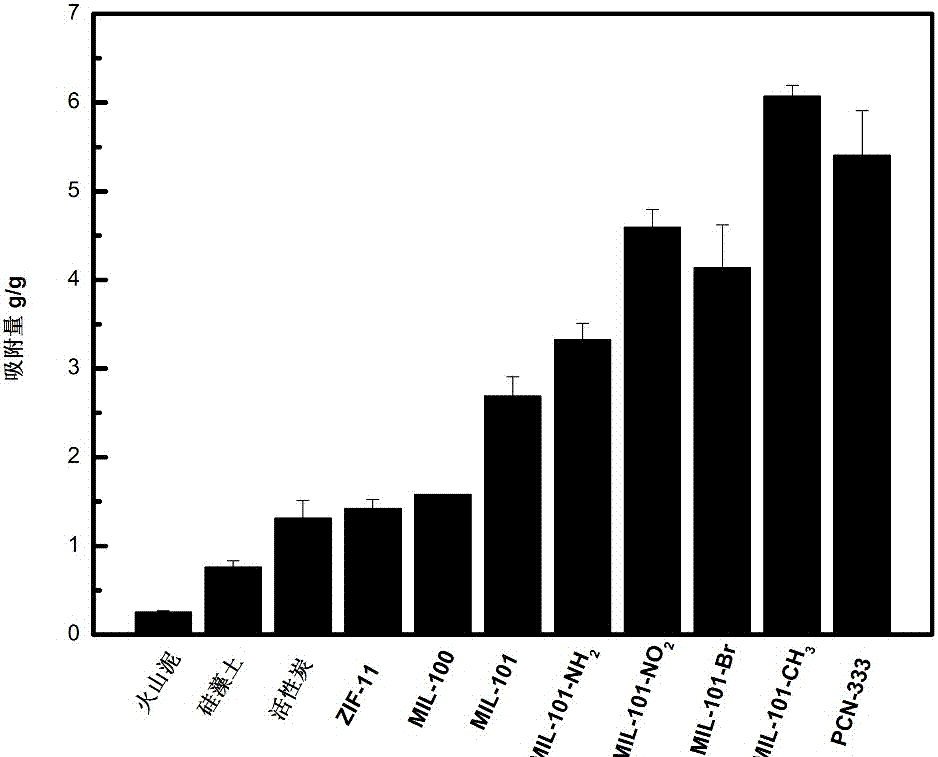

[0043] Test experiment of the adsorption performance of porous frame material on grease:

[0044] Weigh 0.2 g of dried porous framework material into a sealed sample bottle, and vacuumize for 7 hours at 110° C. to remove the solvent in the pores of the material. Add 10 mL of oil into the sample vial with a syringe, stir at room temperature for 20 minutes, filter and wash the adsorbed oil with a 0.22 μm hydrophobic needle filter, and quantitatively detect it. as attached figure 1 As shown, the grease adsorption performance of most porous framework materials is much greater than that of traditional porous materials. Among them, MIL-101-CH with larger specific surface area and larger pore size 3 、MIL-101-NH 2 , MIL-101 and PCN-333, showed stronger oil adsorption capacity than other porous frame materials. In addition, after the structural modification of MIL-101, because the newly introduced functional groups enhanced the interaction between the material and the oil, the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com