Preparing method for ultrafine copper-aluminum alloy powder

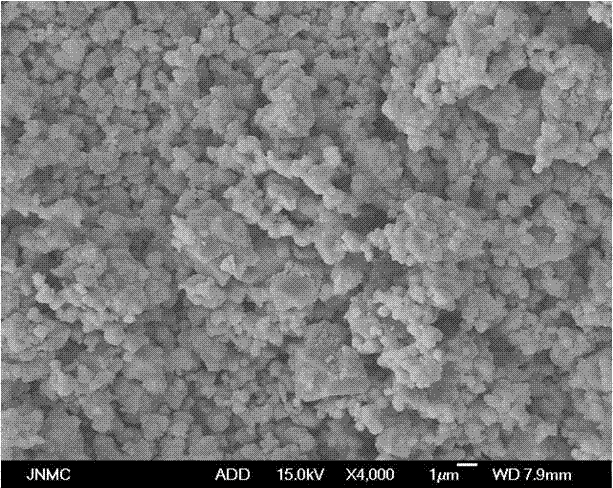

A copper-aluminum alloy and powder technology, which is applied in the field of preparation of ultra-fine copper-aluminum composite powder, can solve the problems of high energy consumption, large powder particle size, and application limitations, and achieve uniform particle size distribution, large specific surface area, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

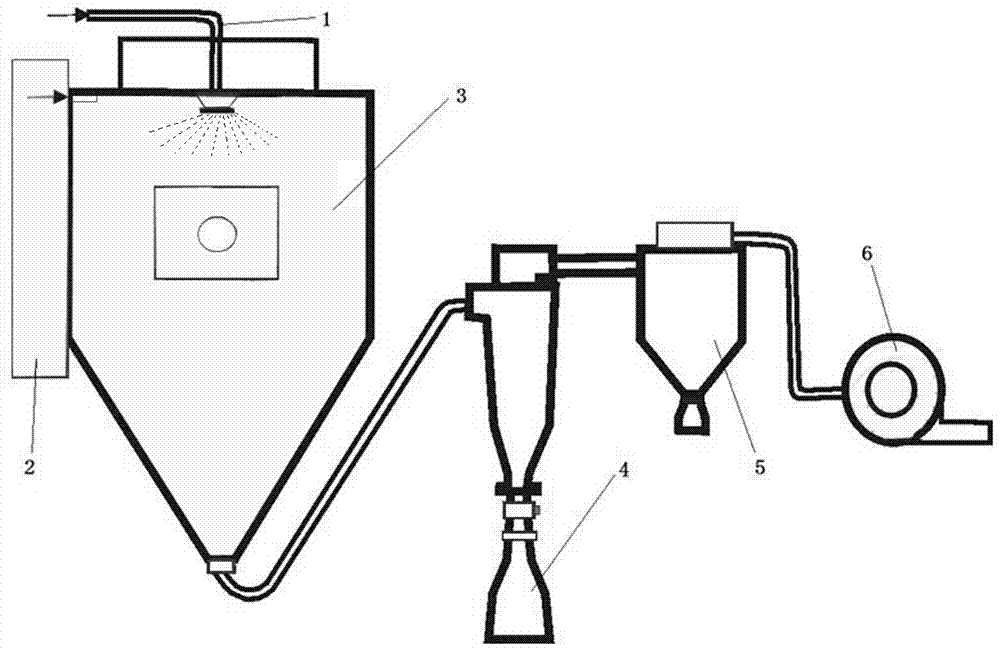

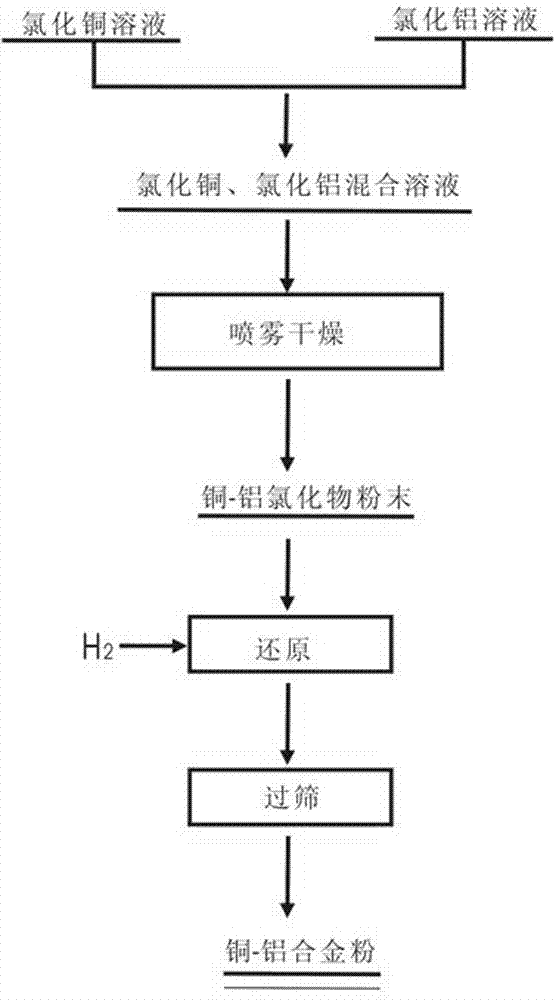

[0019] Prepare the solution with deionized water, in which CuCl in the solution 2 0.31mol / L, AlCl 3 It is 2.96mol / L, stir evenly. Put the mixed solution through the feeding system 1, and use a constant flow pump to control the appropriate flow rate to inject the solution into the high-speed spray device; the atomized solution enters the spray drying furnace; the hot air system 2 controls the spray drying temperature to 180 ° C; collect the initially synthesized Mix the metal chloride powder in the silo 4; control the wind force of the induced draft fan 6, and the bag dust collector 5 captures small particle products. Put the products collected by the silo 4 and the bag dust collector 5 into the reduction furnace, and put hydrogen into the furnace at a temperature of 450° C., and roast for 10 hours. The products obtained after roasting are collected and sieved to obtain superfine copper-aluminum alloy powder.

Embodiment 2

[0021] Prepare the solution with deionized water, in which CuCl in the solution 2 0.39mol / L, AlCl 3 It is 2.78mol / L, stir evenly. Put the mixed solution through the feeding system 1, and use a constant flow pump to control the appropriate flow rate to inject the solution into the high-speed spray device; the atomized solution enters the spray drying furnace; the hot air system 2 controls the spray drying temperature to 200 ° C; collect the initially synthesized Mix the metal chloride powder in the silo 4; control the wind force of the induced draft fan 6, and the bag dust collector 5 captures small particle products. Put the products collected by the silo 4 and the bag filter 5 into the reduction furnace, and put hydrogen into the furnace at a temperature of 470° C., and roast for 8 hours. The products obtained after roasting are collected and sieved to obtain superfine copper-aluminum alloy powder.

Embodiment 3

[0023] Prepare the solution with deionized water, in which CuCl in the solution 2 0.47mol / L, AlCl 3 It is 2.59mol / L, stir evenly. The mixed solution is passed through the feed system 1, and the constant flow pump is used to control the appropriate flow rate to inject the solution into the high-speed spray device; the atomized solution enters the spray drying furnace; the hot air system 2 controls the spray drying temperature to 230 °C; collects the initially synthesized Mix the metal chloride powder in the silo 4; control the wind force of the induced draft fan 6, and the bag dust collector 5 captures small particle products. Put the products collected by the silo 4 and the bag filter 5 into the reduction furnace, and put hydrogen into the furnace at a temperature of 500° C., and roast for 6 hours. The products obtained after roasting are collected and sieved to obtain superfine copper-aluminum alloy powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com