Method for prolonging service life of wicker plaiting crafts

A technology of handicraft and age, applied in the field of willow handicrafts, can solve the problems of short life and fast replacement, and achieve the effect of improving the service life, preventing tissue damage and stabilizing the shape of handicrafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

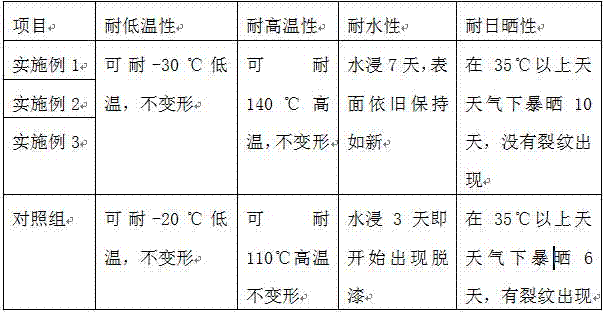

Examples

Embodiment 1

[0016] A method for prolonging the service life of wicker crafts, comprising the following steps:

[0017] (1) Soak the newly harvested willow in ice water for 1 hour, take it out, put it in a steam pot and heat it for 30 minutes, the temperature in the steam pot is 180°C, immerse in ice water again, peel off the willow skin, and then put in softener Soak in medium temperature for 20 minutes, the soaking temperature is 40°C, after soaking, put it into an oven at 80°C and dry until the water content is 10%, then it can be used for weaving;

[0018] (2) Wrap the woven willow handicrafts with plastic film and put them on a baking rack for baking. The baking furnace is equipped with a smoke removal device. By weight: mugwort leaves account for 20%, camphor leaves account for 15%, pomelo peel accounts for 10%, and the rest is cattail. After baking, cool down naturally and remove the plastic film;

[0019] (3) Use a sizing agent to spray wicker handicrafts. The amount of spraying s...

Embodiment 2

[0024] A method for prolonging the service life of wicker crafts, comprising the following steps:

[0025] (1) Soak the newly harvested willow in ice water for 1.5 hours, take it out, put it in a steam pot and heat it for 35 minutes, the temperature in the steam pot is 190°C, immerse it in ice water again, peel off the willow skin, and then put in softener Soak in medium temperature for 25 minutes, the soaking temperature is 42°C, after soaking, put it into an oven at 85°C and dry it until the water content is 12%, then it can be used for weaving;

[0026] (2) Wrap the woven willow handicrafts with plastic film and put them on a baking rack for baking. The baking furnace is equipped with a smoke removal device. By weight: mugwort leaves account for 22%, camphor leaves account for 18%, pomelo peel accounts for 12%, and the rest is cattail. After baking, cool down naturally and remove the plastic film;

[0027] (3) Use a sizing agent to spray wicker handicrafts. The amount of s...

Embodiment 3

[0032] A method for prolonging the service life of wicker crafts, comprising the following steps:

[0033] (1) Soak the newly harvested willow in ice water for 2 hours, take it out and heat it in a steam pot for 40 minutes, the temperature in the steam pot is 200°C, immerse in ice water again, peel off the willow skin, and then put in softener Soak in medium temperature for 30 minutes, the soaking temperature is 45°C, after soaking, put it in a 90°C oven and dry it until the water content is 10-15%, then it can be used for weaving;

[0034] (2) Wrap the woven willow handicrafts with plastic film and put them on a baking rack for baking. The baking furnace is equipped with a smoke removal device. By weight: mugwort leaves account for 25%, camphor leaves account for 20%, pomelo peel accounts for 15%, and the rest is cattail. After baking, cool down naturally and remove the plastic film;

[0035] (3) Use a sizing agent to spray wicker handicrafts. The amount of spraying should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com