High-refraction LED packaging silicone with high gas barrier property

A technology of LED encapsulation and gas barrier, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reduced thermal shock resistance and achieve excellent thermal shock resistance, Easy to operate, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

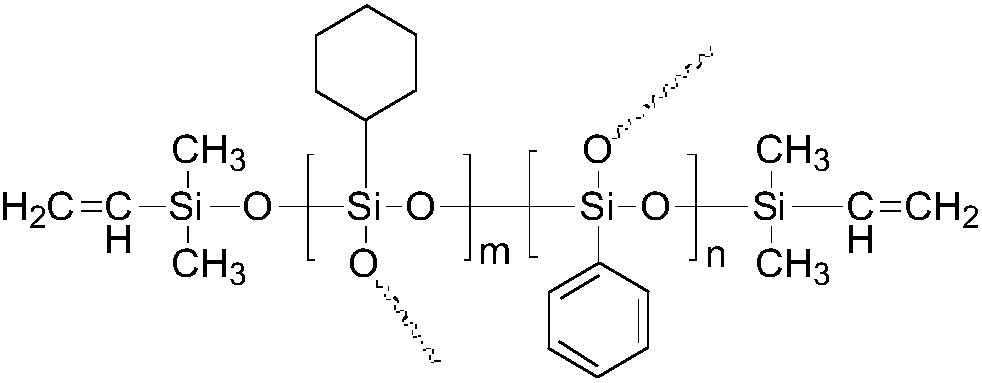

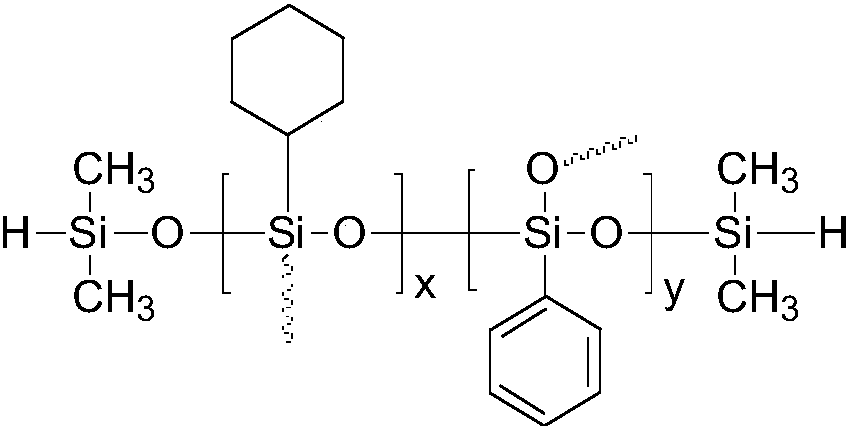

[0040] Preparation of component A: Weigh 24 g of cyclohexane-containing vinyl resin (m=6, n=0 in the structural formula), 17 g of the crosslinking agent (x=0, y=3.5 in the structural formula), ethynyl ring inhibitor 0.10 g of hexanol and 0.5 g of lanthanum oxide surface-modified by phenyltrimethoxysilane and vinyltrimethoxysilane were sequentially added into the mixer, flushed with nitrogen, mixed and stirred evenly, and the A component was obtained.

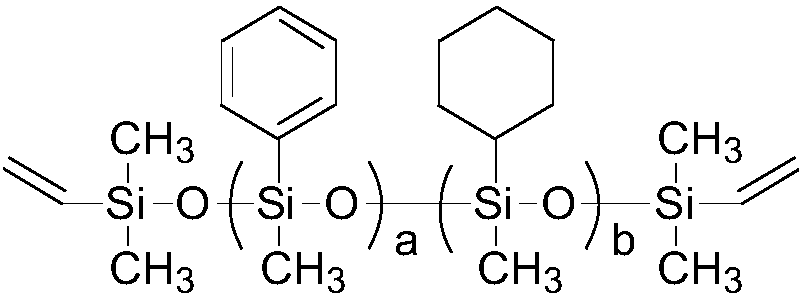

[0041] Preparation of component B: Weigh 6g of vinyl silicone oil (a=8, b=5 in the structural formula), 0.10g of platinum-vinylsiloxane complex (platinum content is 5000ppm), adhesive (coupling agent A The mass ratio to the adhesion promoter B is 1, wherein, for the coupling agent A structural formula n 1 = 2, n 2 =0,n 3 =2) 4g, put into the blender in turn, flush with nitrogen, mix and stir evenly to obtain the B component.

[0042] When in use, mix the above-mentioned components A and B evenly in a weight ratio of 10:1, rem...

Embodiment 2

[0045] Preparation of component A: Weigh 60 g of cyclohexane-containing vinyl resin (m=3, n=2 in the structural formula), 55 g of the crosslinking agent (x=1, y=2 in the structural formula), 55 g of the inhibitor ethynyl ring 0.15 g of hexanol and 5 g of cerium-containing polymethylphenylsiloxane complex were sequentially added into the mixer, flushed with nitrogen gas, and mixed and stirred evenly to obtain the component A.

[0046] Preparation of component B: Weigh 15g of vinyl silicone oil (a=10, b=10 in the structural formula), 0.20g of platinum-vinylsiloxane complex (platinum content is 3000ppm), adhesive (coupling agent A The mass ratio to the adhesion promoter B is 0.5, wherein, for the coupling agent A structural formula n 1 = 2, n 2 =0,n 3 =2) 3g, put into the mixer in sequence, flush with nitrogen, mix and stir evenly, and obtain the B component.

[0047] When in use, mix the above-mentioned components A and B evenly in a weight ratio of 10:1, remove the air bubbl...

Embodiment 3

[0050] Preparation of component A: Weigh 38g of cyclohexane-containing vinyl resin (m=8, n=0 in the structural formula), 15g of the crosslinking agent (x=1.5, y=0.5 in the structural formula), ethynyl ring inhibitor 0.10 g of hexanol and 0.2 g of cerium oxide were sequentially added into the mixer, flushed with nitrogen, mixed and stirred evenly, and the A component was obtained.

[0051] Preparation of component B: Weigh 6g of vinyl silicone oil (a=20, b=15 in the structural formula), 0.10g of platinum-vinylsiloxane complex (platinum content is 5000ppm), adhesive (coupling agent A The mass ratio to the adhesion promoter B is 8, wherein, for the coupling agent A structural formula n 1 = 2, n 2 =0,n 3 =0) 2g, added into the mixer in turn, flushed with nitrogen, mixed and stirred evenly, to obtain the B component.

[0052] When in use, mix the above-mentioned components A and B evenly in a weight ratio of 10:1, remove the air bubbles in the glue in a vacuum, dispense or pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com