A tight oil reservoir anti-co 2 Gas channeling nanocomposite material and preparation method thereof

A nano-composite material and technology for tight oil reservoirs, which are applied in the fields of compounds of Group 4/14 elements of the periodic table, drilling compositions, organic chemical methods, etc., can solve the problems of insignificant application benefits of tight oil reservoirs and achieve The effect of good flow performance, low damage rate and good injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Anti-CO 2 The preparation of gas channeling nanocomposites, the steps are as follows:

[0059] (1) Preparation of nano silicon dioxide

[0060] Add 200ml absolute ethanol, 14.6g concentrated ammonia water (concentration 35%) and 3.4g distilled water successively in the 500ml three-necked flask, place the mixed solvent in a water bath with a magnetic stirrer, and stir rapidly for 30min to ensure that the solvent is evenly mixed; then , under the condition of rapid stirring, quickly add 74.6g of ethyl orthosilicate to the mixed solvent, and react at a constant temperature of 25°C for 24h; after cooling, centrifuge, dialyze, remove unreacted raw materials and solvents, purify multiple times, and dry dry to obtain nano-silica, referred to as SNPs, with a particle size of 20-40nm.

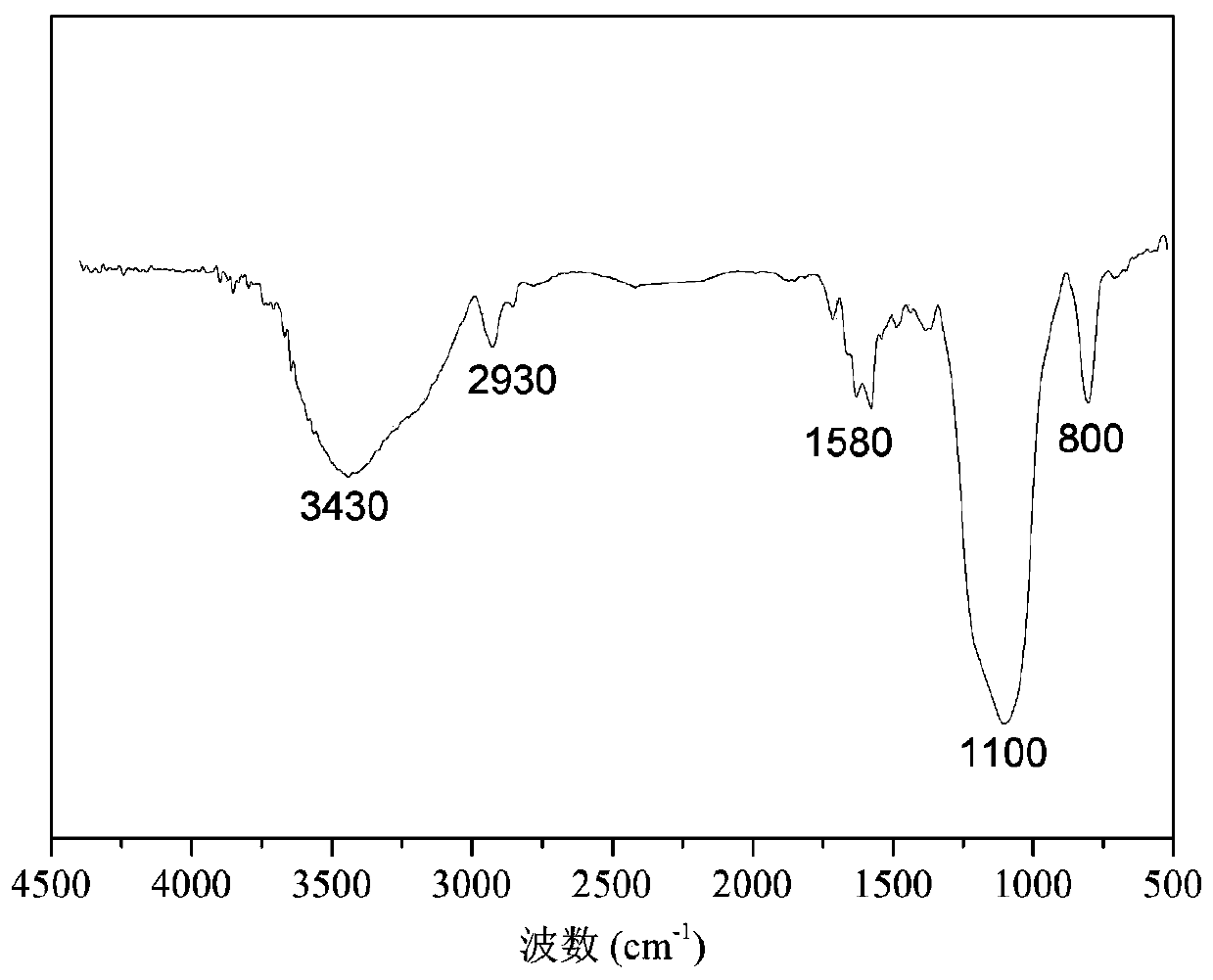

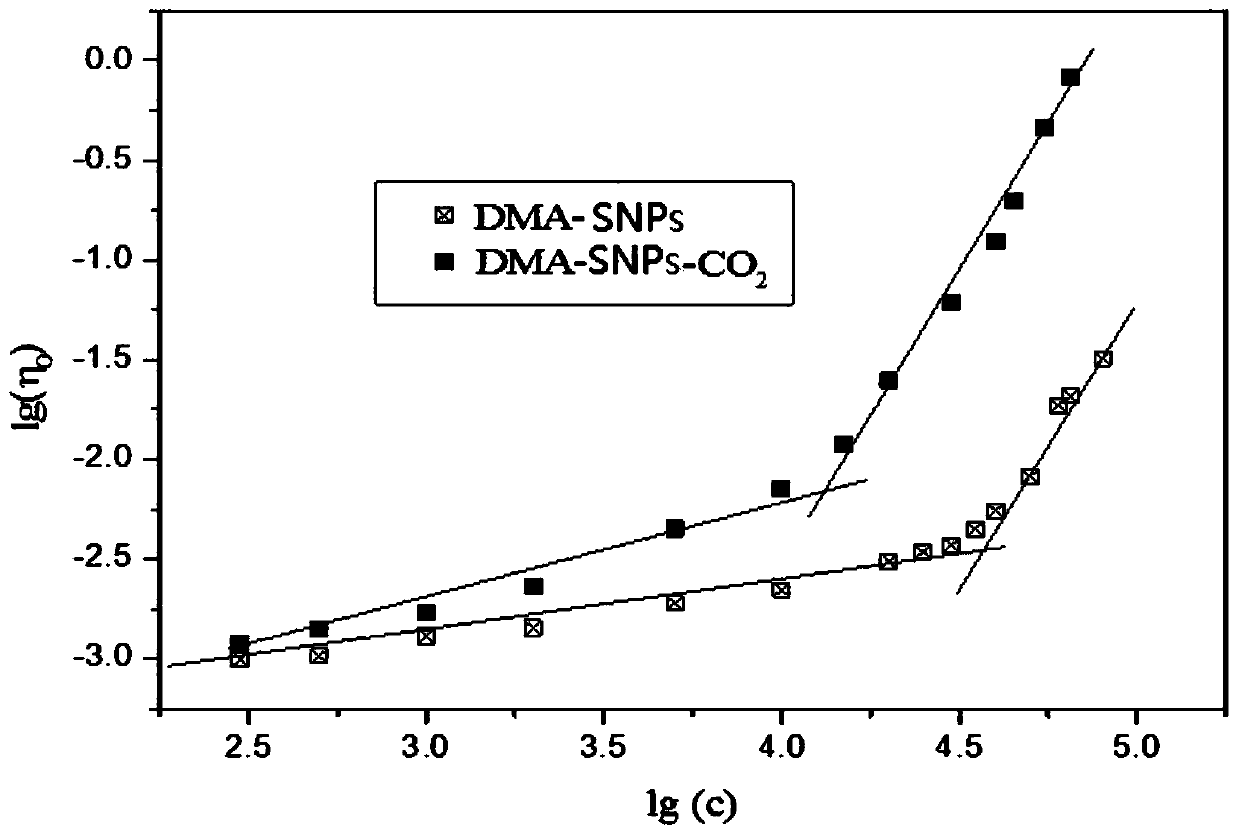

[0061] (2) Surface modification of nano-silica

[0062] Weigh 7.5g of SNPs and dry them under vacuum at 100°C for 24h, then disperse them in 150ml of toluene, and treat them with ultrasonic wa...

Embodiment 2

[0068] Anti-CO 2 The preparation of gas channeling nanocomposites, the steps are as follows:

[0069] (1) Preparation of nano silicon dioxide

[0070] Add 300ml absolute ethanol, 21.9g concentrated ammonia water (concentration 35%) and 5.1g distilled water successively in the 500ml three-necked flask, place the mixed solvent in a water bath with a magnetic stirrer, and stir rapidly for 30min to ensure that the solvent is evenly mixed; then , under rapid stirring conditions, quickly add 89.6g orthosilicate ethyl ester to the mixed solvent, and react at a constant temperature of 25 °C for 24 hours; after cooling, centrifuge, dialyze, remove unreacted raw materials and solvents, purify multiple times, and dry dry to obtain nano-silica, referred to as SNPs, with a particle size of 20-40nm.

[0071] (2) Surface modification of nano-silica

[0072] Weigh 9.8g of SNPs, dry them under vacuum at 100°C for 24h, disperse them in 150ml of toluene, and treat them with ultrasonic waves f...

Embodiment 3

[0078] Anti-CO 2 The preparation of gas channeling nanocomposites, the steps are as follows:

[0079] (1) Preparation of nano silicon dioxide

[0080] In a 500ml three-necked flask, add 300ml of absolute ethanol, 7.3g of concentrated ammonia (concentration 35%) and 2.4g of distilled water successively, place the mixed solvent in a water bath with a magnetic stirrer, stir rapidly for 30min, and ensure that the solvent is evenly mixed; then , under the condition of rapid stirring, quickly add 52.3g ethyl orthosilicate to the mixed solvent, and react at a constant temperature at 25°C for 24h; after cooling, centrifuge, dialyze, remove unreacted raw materials and solvents, purify multiple times, and dry dry to obtain nano-silica, referred to as SNPs, with a particle size of 20-40nm.

[0081] (2) Surface modification of nano-silica

[0082] Weigh 6.0g of SNPs, dry in vacuum at 100°C for 24h, disperse in 150ml of toluene, and ultrasonically treat for 30min; then, transfer the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com